Snijders Intelligent Automation designs and manufactures electrical panels for many industrial and commercial sectors, including maritime. The Barwon Water biosolids drying facility is a fully enclosed thermal drying operation in Australia. Both are using PROFIBUS to maximize transparency and uptime.

Snijder’s monitors PROFIBUS in hazardous environments

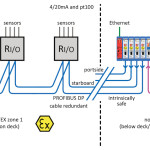

Snijders Intelligent Automation designs and manufactures electrical panels for many industrial and commercial sectors, including maritime. Snijders is responsible for designing, constructing, installation and commissioning of a finished system. Snijders recently fully automated and installed PROFIBUS in four newly built tankers. These tankers have various potentially explosive atmospheres for which ATEX directives apply. That is why Snijders used the ComBricks RS 485 Intrinsic Safety barrier modules by PROCENTEC. This allows for 24/7 remote monitoring of the PROFIBUS installation from a safe zone.

Click an image to view gallery

Read the Application Story here.

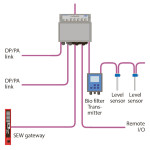

Barwon Water increases PROFIBUS network reliability and robustness

The Barwon Water biosolids drying facility is a fully enclosed thermal drying operation in Australia. The facility provides an environmentally sustainable, long-term solution for reclamation of 100% of the biosolids produced at the Barwon Water’s Black Rock and smaller regional water treatment facilities. In order to keep the PROFIBUS system going, Barwon Water uses PROCENTEC ProfiHubs. By using these multi-functional network components the facility is continually assured of the most reliable, high quality and robust PROFIBUS network with the highest uptime.

Click an image to view gallery