Instead of milk, the small dairy simply processes water. The finished product is not going to be used for anything at all, but will just go down the drain once it has been through the process. And what is the point of that? Well, whether the dairy processes water or milk, the process is exactly the same, and this dairy has been established solely for the purpose of training the company’s customers, so it is actually quite logical.

The automation of dairies is our main competence

The new ‘dairy’ has been built at Automate, a company that specializes in the automation of dairy and other process-oriented plants in the food industry.

In addition to supplying automation, Automate also offers to lead projects. And now there is an additional skill on offer, namely training at the Automate Academy as the mini-dairy is called. A room next to the dairy has been set up as a classroom for 10 students, each with their own PC screen.

In addition to supplying automation, Automate also offers to lead projects. And now there is an additional skill on offer, namely training at the Automate Academy as the mini-dairy is called. A room next to the dairy has been set up as a classroom for 10 students, each with their own PC screen.

The need for customer training

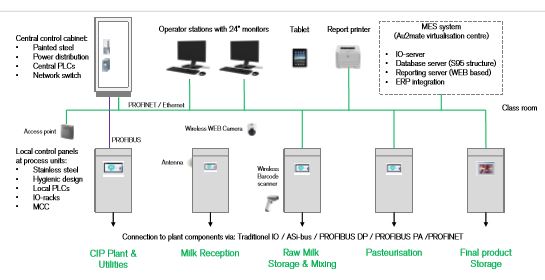

The processing facility incorporating line control consists of raw material reception, storage, pasteurization, buffer tanks, delivery/filling, and clean-in-place (CIP) system. The facility has been built in mini-scale, but to full industrial standards, and all instrumentation (PLC, SCADA & MES) is up to industry standards and best practice, e.g. S88 and S95.

Technical director, Carsten G. Jensen, explains, “The management of a dairy has three requirements that must be met: reliability, reliability, and reliability! And that is where our courses come into the picture. Because we can train the dairy operators how to use the equipment correctly, and at this facility the consequences of an operator error are not so serious. In the event of a fault, the dairy’s service technicians must be familiar with the equipment and be able to use the diagnostic tools effectively to find and fix the fault. That is why a training facility like this must be able to relate to the real world”.

The technical side

Carsten G. Jensen continues, “The automation of the training dairy has been designed in exactly the same way as we do it at real production dairies. We have a Wonderware SCADA-system platform, Siemens and Allen Bradley PLC controllers, HMI panels and IO slaves, and frequency transformers from Danfoss, Siemens, and Allen Bradley. The processing instrumentation is also from several different suppliers, because we make a point of training customers on the very same equipment as they have at their own dairy.”

Communication

Fieldbuses and communication nets are becoming more and more important in any large system. It is particularly important that networks are robust and reliable. They can and must help maintain a high uptime in the system. A modern network must be able to use any relevant medium: copper cable, optical fiber, wireless, or radio.

These requirements are met by the fieldbuses and network used at the training facility and by Automate in automation projects.

The fieldbuses used at the training facility are PROFINET, PROFIBUS DP, and PROFIBUS PA. AS-i buses are also used, for example to control on/off valves.

Communication between the five independent modules that make up the dairy and the user stations and HMI panels is carried out by PROFINET copper cable or PROFINET wireless.

Many-sided use of the dairy

Carsten G. Jensen adds, “We have trained a lot of people from our customers at home and abroad since we opened the Automate Academy in the spring of 2016. But we also use the dairy in sales presentations, where we can simply show a customer a complex function, which might otherwise take a lot of explaining and still be difficult for the customer to understand.”

“We also use the dairy to train our own employees, of course, and it has been used by students from Aarhus University School of Engineering for examination projects in regulating machinery. It has been a significant investment to construct such a dairy for training, but it has already shown itself to have been a good investment.”