It has been quite a road for the Working Groups of PI these past couple of years. Working Groups are where all of the technical advancements are made on the PROFIBUS, PROFINET, and IO-Link specifications. Working Groups are staffed by some of the smartest engineers in the industry from companies big and small. These folks volunteer their time to help drive our technologies forward, and one Working Group has been particularly busy.

Industrie 4.0 Working Group

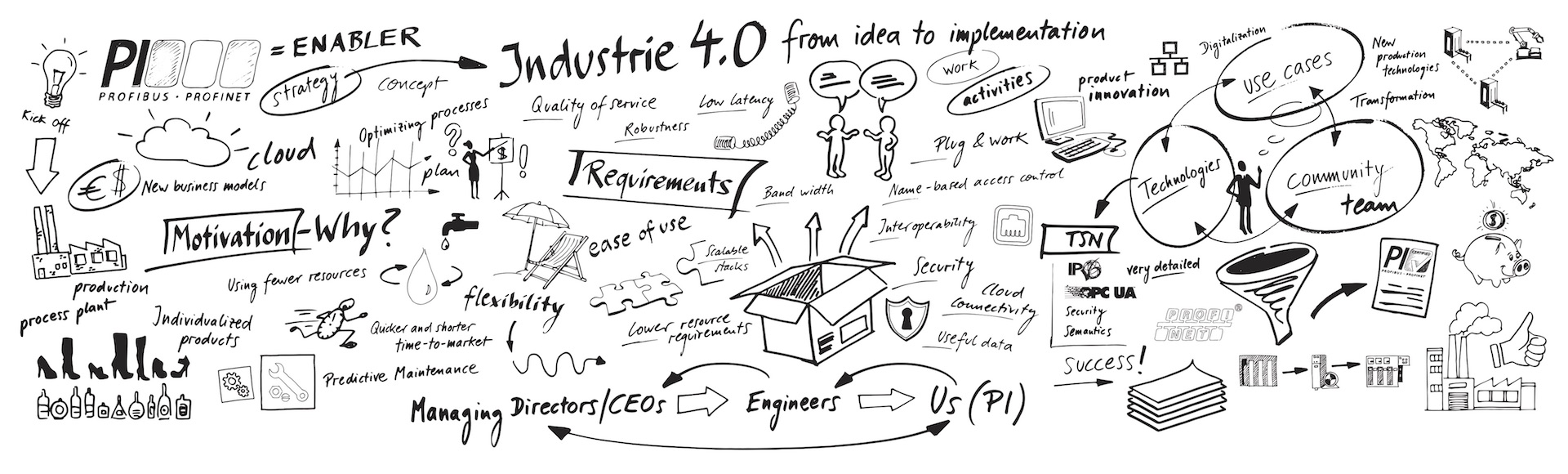

The Industrie 4.0 Working Group (I4.0 WG) was initially convened in 2015 when trends like the Industrial Internet of Things were first gaining traction. At the time, the group was tasked with turning concepts into reality. Instead of blindly adopting new technologies for technology’s sake, a different approach was taken. The group first came up with a long list of requirements in collaboration with input from end-users across vertical markets. These were then prioritized and the I4.0 WG became a ‘meta-group’ of sorts. Sub-topics were assigned where new solutions could address the requirements collected previously. Three main areas were highlighted.

Let’s Simplify

The first topic you need to familiarize yourself with for 2019 is Time Sensitive Networking (TSN). It’s all about making life less complicated. Deterministic networking is fundamental in factory automation. With PROFIBUS, determinism was achieved via a closed fieldbus. Since PROFINET runs on standard open Ethernet, which is not deterministic by design, some additional functions were built into the PROFINET protocol to achieve this determinism. Namely, the protocol skips Layers 3-4 of the ISO/OSI Model and goes straight from Layer 2 to Layer 7. Furthermore, PROFINET Isochronous Real Time (IRT) adds features like bandwidth reservation, synchronization, and scheduling to go even faster for high-speed motion control.

Now that other industries outside of factory automation are interested in deterministic Ethernet, the features we’ve built into PROFINET for 15 years are becoming IEEE standards known as TSN. This simplifies networking, as determinism can be taken for granted via TSN mechanisms. While it may sound trivial on the surface to bring the TSN tools into the PROFINET specification, in fact it has taken a few years of continuous effort within the I4.0 WG. Come mid-2019 however, PI will release its PROFINET@TSN spec, and we expect first products to hit the market in 2020. This is no small feat, so if you haven’t familiarized yourself with TSN yet, now is the time.

Let’s Integrate

The second main topic highlighted was that of horizontal/vertical integration. In other words, how can we reduce the effort spent in gaining access to data. The ROI of any integration project quickly diminishes the more difficult it is to access, sanitize and (most importantly) harmonize data from manufacturing lines. To that end, by mid-2019 PI plans to release its PROFINET / OPC UA Companion Specification. OPC UA has become the de-facto standard for interoperable information exchange from the shop floor to the top floor. With its robust object-oriented information model and platform independence, OPC UA is proving to be the most efficient way to move semantic information around a plant.

The concept of machine-to-machine (horizontal) integration is nothing new for PROFINET. In fact, the very first version of the protocol was used in this fashion before being expanded to I/O data exchange. So instead of reinventing the wheel, the I4.0 WG made the decision to adopt OPC UA as the best way to integrate PROFINET from Controller to Controller. In combination with TSN, OPC UA allows best in class machines from various vendors to communicate deterministically.

For vertical integration, the Companion Specification will begin with a mapping of the following acyclic PROFINET services to OPC UA objects: diagnostics and Asset Management Records. With such data made available via OPC UA, it can more easily be accessed by higher level systems. For example, with diagnostics mapping, the Alarms & Conditions functionality of OPC UA could be leveraged. Regarding Asset Management Records, the goal is to further advance the concept of the Administration Shell within the context of digitalization. The ability to gather detailed Asset Management Records from PROFINET devices via OPC UA will help in the creation of a digital twin for a given machine.

Let’s Process

The final topic to familiarize yourself over the coming years is that of the Advanced Physical Layer (APL). If the advancements for Ethernet known as TSN will be felt most in discrete manufacturing, then the advancements to Ethernet known as APL will be felt most in continuous process control applications. But where TSN mechanisms operate at Layer 2 of the ISO/OSI Model, APL operates at Layer 1. The goal here is to bring Ethernet down to field level instruments in hazardous areas.

As instruments get more complex and more data becomes available, the need for increased bandwidth to access this data is becoming apparent. Ethernet provides this, with the added benefit of being a well-known standard. The forthcoming Advanced Physical Layer will be based on single pair cabling, already familiar from the PROFIBUS PA world. Similarly, both power and communication will be transmitted via these wires. Finally, APL will exceed the 100m limit currently imposed on common 100BASE-TX Ethernet networks.

Since this is an advancement of Ethernet itself, and not just PROFINET, PI is collaborating with other fieldbus organizations on this work. Therefore, the timeline for APL is a bit longer than that of TSN implementation or the OPC UA Companion Specification. Work on APL is not expected to be completed before the year 2020 or 2021.

We all know that in manufacturing markets, things don’t happen quickly, but in reality, these technologies will be here before we know it. Other technologies we are keeping our eye on include IPv6 and how best to address security. Stay tuned to this space to keep yourself updated as to the latest.

Michael Bowne

Deputy Chairman, PI