Ethernet-APL: the Final Push

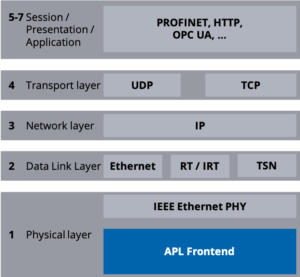

The development of a two-wire-based advanced physical layer (APL) for Ethernet is running at full speed. It is intended for the fields of process automation and process instrumentation in order to deploy field devices with additional functions and without protocol translations at remote and explosion-hazardous locations.

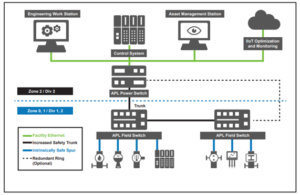

“Ethernet down to the field level” is an enabling technology for new technological developments such as the Industrial Internet of Things (IIoT) and the German Industry 4.0 initiative. Both have introduced new paradigms to facilitate applications based on the digital real-time presentation of almost any object. Furthermore, automation manufacturers are facing the challenge of creating simple, efficient, and yet secure access to the field level, through concepts such as NAMUR Open Architecture (NOA).

“Ethernet down to the field level” is an enabling technology for new technological developments such as the Industrial Internet of Things (IIoT) and the German Industry 4.0 initiative. Both have introduced new paradigms to facilitate applications based on the digital real-time presentation of almost any object. Furthermore, automation manufacturers are facing the challenge of creating simple, efficient, and yet secure access to the field level, through concepts such as NAMUR Open Architecture (NOA).

The limits of today’s communication interfaces are quickly reached in the realization of new data-intensive applications. Thus, the process industry of the future needs a networking standard that can transmit process data from devices via communication systems with the speed and flexibility of standard Ethernet and of the communication protocols that are built upon it.

A project team consisting of specialists representing three organizations and eleven automation vendors has already been working cooperatively since 2017 on the implementation of a suitable communication interface for the future. The interface also incorporates the specifications outlined in NAMUR Recommendation NE168 (“Requirements for a field level Ethernet communication system”), which was just published in November of last year.

The future IEEE 802.3cg (10BASE-T1L) standard forms the basis of Ethernet-APL. The working group is in the process of releasing a specification for a two-wire Ethernet for cable lengths of up to 1000 m at a transmission rate of 10 Mbps full duplex. The project is on schedule, with completion expected by the fourth quarter of 2019. This will allow manufacturers of 10BASE-T1L PHYs (Communication ASICS) to finalize their product development. Besides the process industry, there are countless businesses in other segments (e.g. building automation) that have big plans with this new communication standard.

The requirement for explosion protection remains a special feature in the process industry. Ethernet-APL will support essentially all relevant types of ignition protection. In order to support the widely popular protection method “intrinsic safety”, suitable parameters have been specified. As a next step, these parameters shall be included in an IEC technical specification (TS). The IEC issued a call for interest for an IEC-TS that was met with a very positive response from many countries. This IEC-TS defines an intrinsically safe Ethernet-APL both for product development and for field application – as simple as it was under the term FISCO at Profibus PA. This new technical specification is currently being developed under the name 2WISE (“2-wire intrinsically safe Ethernet”).

The requirement for explosion protection remains a special feature in the process industry. Ethernet-APL will support essentially all relevant types of ignition protection. In order to support the widely popular protection method “intrinsic safety”, suitable parameters have been specified. As a next step, these parameters shall be included in an IEC technical specification (TS). The IEC issued a call for interest for an IEC-TS that was met with a very positive response from many countries. This IEC-TS defines an intrinsically safe Ethernet-APL both for product development and for field application – as simple as it was under the term FISCO at Profibus PA. This new technical specification is currently being developed under the name 2WISE (“2-wire intrinsically safe Ethernet”).

An important core task of the APL project team is to ensure the interoperability of APL components. This includes the specification of intrinsically safe communication and power supply, as well as the associated profiles so that industrial Ethernet field devices can be used in explosion-hazardous areas up to zone 0 or class 1/division 1. The team also places a high priority on the topic of ensuring the conformity, and thus interoperability, of the devices. The functional conformity of future Ethernet-APL devices will be tested and certified by licensed certification bodies at the organizations PI, FieldComm Group, and ODVA.

A Step Ahead

APL@10Mbps is becoming the core technology for Ethernet down to the field. However, there are certain applications that seem to need an even higher data rate. That is why the feasibility of a 100 Mbs solution – known as APL Phase 2 – is already being studied. Ongoing tests have revealed that a technological solution is indeed possible. However, experiences have made one thing clear: a 100 Mbps solution on the market is only possible via an IEEE standardization. That is why all industrial sectors are currently being scoured for further supporters – that is, those who also need a solution with 100 Mbps, 200–500 m segment length via two-wire communication.

Ethernet-APL is an important investment on the part of manufacturers of field devices, vendors of automation systems and suppliers of infrastructure components. All of these stakeholders share the same vision of a single, common, and transparent physical layer for Ethernet in the field of process automation. If Ethernet-APL communication is based on established IEEE and IEC standards and is certified in every region of the world, we can expect it to experience widespread market acceptance.

Technology Outlook

Ethernet-APL is a fundamental technology that enables broad and innovative product development. From engineering firms to module and plant manufacturers, from service providers and data suppliers to consumers – everyone stands to benefit from the digitalization of process industries. The ability to transmit Ethernet communication with power supply via a single, two-wire cable will result in a new, easy-to-use physical layer and thus an entirely new generation of field devices and infrastructure components. This will simplify process technology and allow for completely new applications. The possibilities here appear to be practically limitless.

APL Project Team