PROFIdrive in Machines and Models

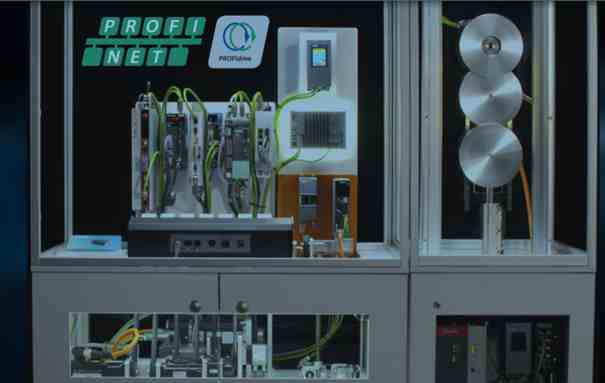

A new demo model at the joint PI booth at the 2023 Hanover Fair vividly shows both the smooth interaction between different drive manufacturers and the added value of PROFIdrive standardization for simulation.

Products from eleven different manufacturers work together smoothly in a demanding drive application on a single machine. This application is based on synchronous communication using PROFINET IRT with the addition of the PROFIdrive profile Application Class 4 (AC4). The profile provides an interoperable interface for multi-axis motion control applications. These and other drives with IRT can be seen on the PI website at this link: https://www.profibus.com/technology/profidrive/profinet-irt-drive-vendors. The wide variety of drives gives machine builders the ability to find the right drive to easily handle their motion application..

In addition to the expanding selection of motion products that support PROFIdrive, there is the emerging requirement for simulation prior to physical construction. Easy commissioning is also becoming increasingly important. However, the effort required – especially in creating the models – may not outweigh the benefits. This is where PROFIdrive plays a critical role – the advantage of high standardization with PROFIdrive, including the state machines it contains, can be seen here:

- Easy and convenient commissioning of drives from different manufacturers using technology objects

- Virtual commissioning before the physical machine is built, resulting in higher quality and efficiency

- PROFIdrive integration enables existing simulation models to be used.

The specific process and advantages can be seen at a dialog station at the model. All in all, the large variety of drives with PROFINET IRT and PROFIdrive along with the additional advantage of support for simulation and planning provide both for manufacturers and users a comprehensive and complete solution.

PROFIsafe Integration into the World of Drives

The integration of PROFIsafe into the world of drives is making great strides and further completing the PROFINET/PROFIsafe ecosystem. The options for safety-related automation solutions with PROFIsafe – a leading failsafe communication protocol – are becoming increasingly more comprehensive as a result.

In addition to the well-known and previously common safety-related components like emergency-stop buttons, safety I/Os, laser scanners and door closers, the advancing integration of PROFIsafe into the world of drives opens up a large selection of manufacturers of different drive components. This means a machine builder can assemble an effective system solution with integrated safety functions. This is also reflected in the growing number of drive manufacturers actively participating in the newly designed PROFIsafe live demo, which can be seen at the joint PI stand at the Hanover Fair. Stöber and KEB, in addition to SEW and others, are now represented with their PROFIsafe safety-related converters as well.

Device variety is not the only thing continuing to develop, though, as the technology is also advancing. The PI (PROFIBUS & PROFINET International) Working Group recently expanded the specification enabling the simplification of safety addressing, primarily in flexible and large systems.