With the growing focus on digitalization, sustainability, and worker safety, PROFINET is seeing a resurgence in the use of Application Profiles. In this three-part series, we will look at the three application profiles fueling this resurgence – PROFIsafe, PROFIenergy, and PROFIdrive.

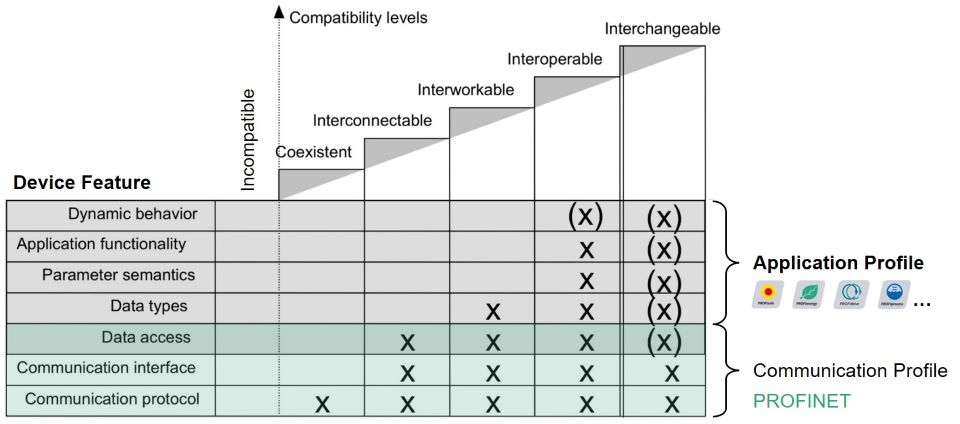

For those unfamiliar with Application Profiles, what we’re talking about, when we talk about Application Profiles, is increasing the level of compatibility between devices in a network. As can be seen in the figure below, the PROFINET specification provides the first level of compatibility by standardizing the protocol, interfaces, and data access. Here, we can achieve co-existence and interconnectability at the communication level. Application Profiles take it a step further by standardizing data types, semantics, and functionality. Here, we can achieve not only interoperability but even device interchangeability. Each Application Profile is specified and written by PI, just like the PROFINET protocol.

Application Profiles work by structuring data in a consistent object format for a family of devices. In other words, a family of devices always has its data modeled the same way. For just about every step in a manufacturing process, there is an Application Profile. In PI we have roughly two dozen in total. There are Application Profiles for low voltage switch gear, one for RFIDs, one for drives, for encoders, and so on. The way it works is this: if a device’s description file is written to its Application Profile, then independent of vendor or type, parameters like voltage, or position, or RPM always come into your engineering tool the same way for easy integration. And while Application Profiles are extremely useful, they are optional –a device manufacturer doesn’t need to make their product compatible, it’s just that most do because of market demand. Let’s take a look at the first of three application profiles gaining momentum with this latest market demand: PROFIsafe.

PROFIsafe

We start with the application profile having to do with functional safety. Functional safety is exactly that: it protects people and things from incorrect functioning. But that’s only part of the overall safety of a system or a machine – we’re not talking about protecting ourselves from things like fire, or radiation. We are focused specifically on protection from – for example – a robot coming around and hitting someone or something and causing damage. For that we have an Application Profile called PROFIsafe. PROFIsafe provides functional safety over the network by ensuring the reliable transmission of safety messages – and that’s all that it does – but this is significant in what it enables.

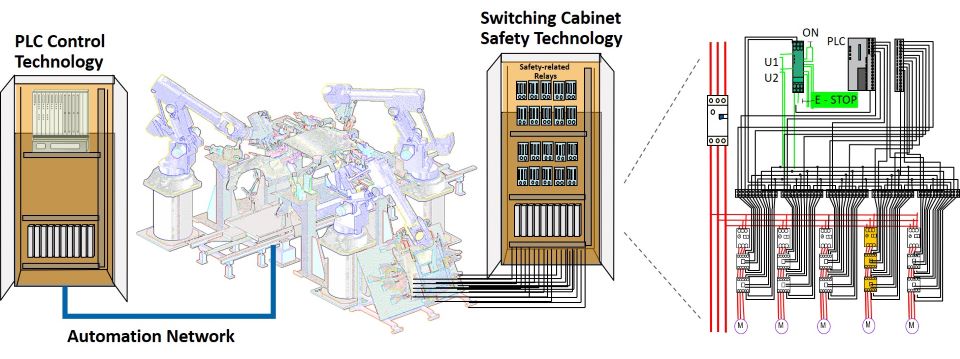

It’s not a new idea. It’s just that in the past when you wanted to wire up an e-stop button, for example, it required lots of wires, terminal strips, marshalling racks, and relays all inside a large cabinet as shown in the figure below. When the e-stop button is pressed, whatever is programmed in the relays actually happens – maybe like turning off a robot or a conveyor belt. If we look back in time before PROFIsafe, there was a dedicated network for automation – back then, in those days, it was PROFIBUS – and an entirely separate network for functional safety.

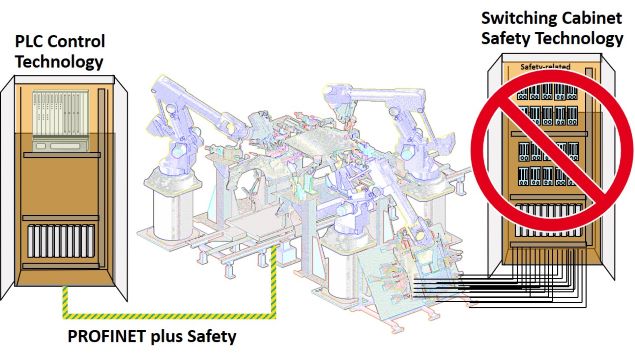

But with PROFIsafe, instead of hardwiring and home running all of your safety sensors and safety actuators back to the cabinet, you connect them to PROFINET. These connected devices send and receive safety messages over the same PROFINET network as the automation traffic. And then instead of doing safety in hard relays, safety is programmed into a controller. Or as we say: ‘Safety-in-Logic’. This allows you to get rid of all of those terminal strips, marshalling racks, and relays, saving power, space, and time – especially when things change down the road.

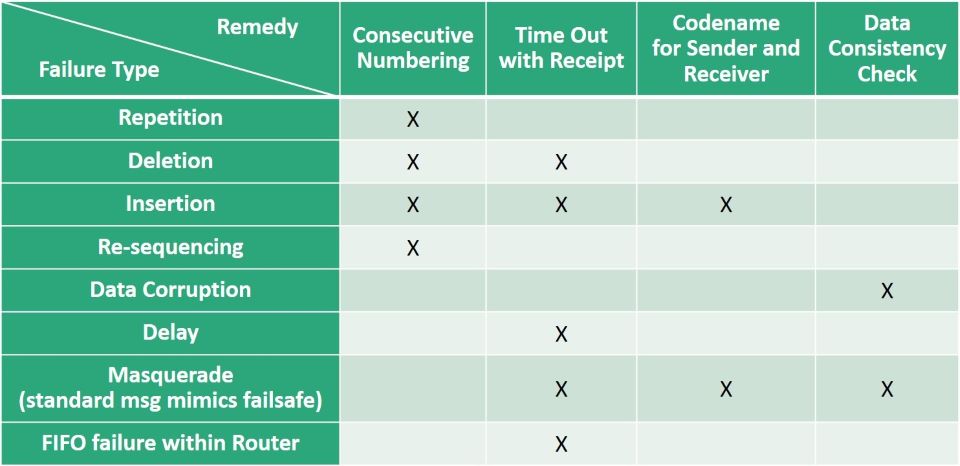

Now, if that emergency-stop is hardwired back to a relay, you know in your heart of hearts, that when the e-stop button is pressed, the relay will flip. But what happens now, if we are sending safety messages over our PROFINET network? Of course things can go wrong – like, a message could be repeated or deleted, or it could get out of sequence. It could become corrupted or delayed, or an Ethernet switch or router could even cause first-in-first out failures. So, PROFIsafe uses 4 remedies to mitigate any possible failure type as shown in the table below. First, we number every PROFIsafe message consecutively. Second, we use a timeout, or watchdog timer. Third, we use unique codenames between PROFIsafe message senders and receivers. And finally, we do a data consistency check, or CRC. With these four remedies we are able to ensure the reliable transmission of safety messages over the network.

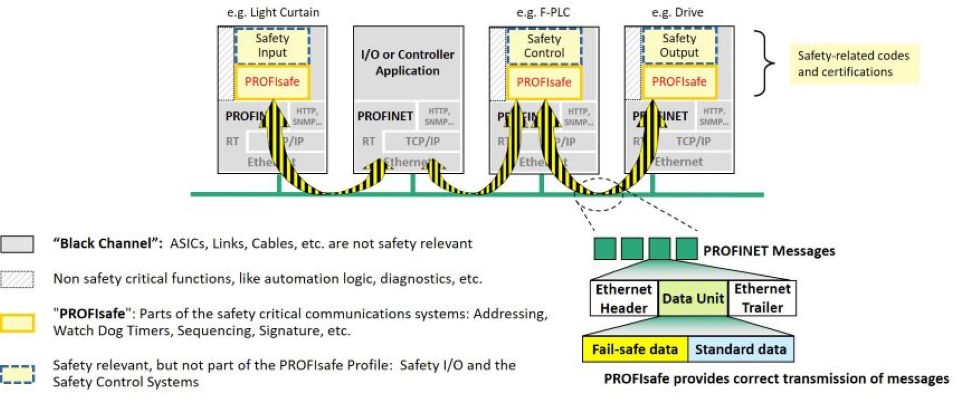

The way it works is this: PROFIsafe messages are just regular PROFINET messages but with some extra fail-safe data added to support the four remedies defined in the table above. And then, PROFIsafe uses the black channel principle to send safety messages from one end of the network to the other end. The black channel principle means, we don’t care about the underlying transport or physical layer. All we care about is that PROFIsafe messages get from Point A to Point B. So, for example, it’s like we are showing in the figure below where we are sending safety data from the light curtain to the safety PLC, and then from the safety PLC to the drive. Notice that PROFIsafe messages can travel through non-safety related devices like a remote I/O or Ethernet switch, and it is still safe because of the black channel principle. PROFIsafe messages can also travel over any physical layer. The physical layer can be copper, it can be fiber, it can even be wireless. And just to be clear, about the the safety hardware itself – like the safety inputs, safety control, and safety outputs – this hardware must still undergo their own system reliability testing, but this is outside of the scope of PROFIsafe.

To dig deeper into the technical details and inner workings of PROFIsafe, download the PROFIsafe System Description here: System Description – PROFIsafe Technology and Application

In the next issue of PROFInews, we will look at Part 2, the second application profile gaining momentum: PROFIenergy.