Introduction

Preventive fire protection systems are of central importance in industrial production – not only to protect people and systems, but also to avoid production downtimes. With the GreCon PROTECTOR, Fagus-GreCon and MESCO Engineering have created an innovative, highly integrated system that sets standards in terms of safety, decentralization and communication capability. Honored with the iF DESIGN AWARD 2025 in gold, the GreCon PROTECTOR combines practice-oriented design with functional safety in accordance with current standards.

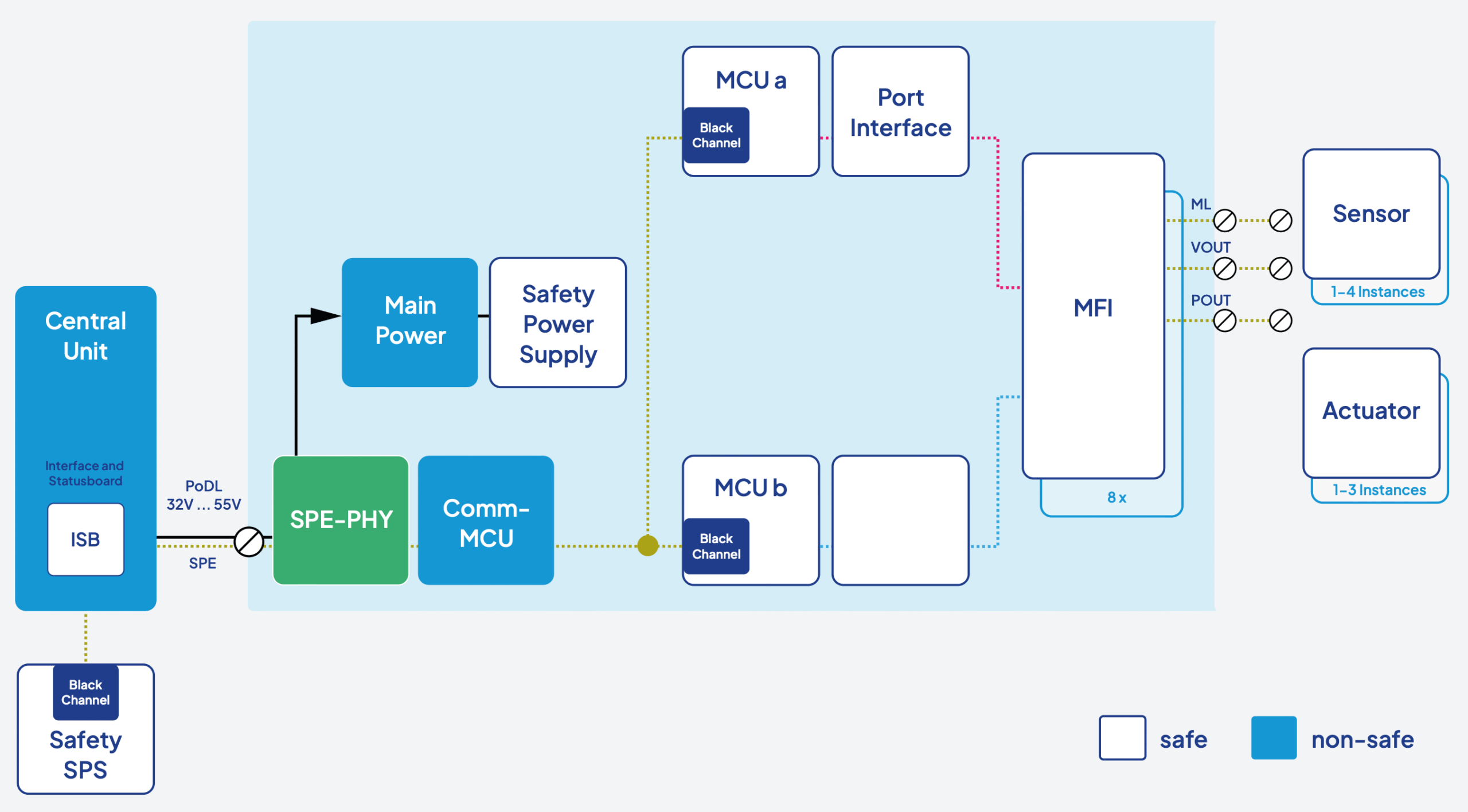

Intelligent System Architecture: the Ranger Control Module

Decentralized Control

The core component of the system is the Ranger control module, which is installed directly in the vicinity of the system area to be monitored. This decentralized architecture reduces the need for central control cabinets and increases the modularity and scalability of the system.

Energy and Data Transmission via SPE

The Ranger communicates with the system centre via Single Pair Ethernet (SPE). This technology enables both full-duplex data transmission and Power over Data Line (PoDL) via a single twisted pair of wires.

- Transmission power: up to 50 W

- Data rate: 10 Mbit/s

- Range: up to 1,000 m

- Basis for standardization:

- IEEE 802.3cg (10BASE-T1L)

- IEEE 802.3bu (PoDL)

SPE was selected as the communication medium as it saves cabling costs. In addition, an electrically isolated power supply increases operational reliability.

Secure Communication: PROFINET and PROFIsafe in Use

The system uses PROFINET, a widely used industrial Ethernet protocol that is optimized for cyclical, deterministic data exchange between control systems and field devices. (IEC 61158 / IEC 61784-3-3 PROFIsafe). PROFIsafe – a safety protocol based on PROFINET – is used to transmit safety-related data. This enables the safe shutdown of machines in the event of a fault, which is essential for machine protection.

The Safety-Relevant Hardware and Software Architecture

Hardware Architecture:

The safety of the system is realized by a 1oo2 safety architecture, developed with the MESCO Safety Design Package, which uses the STM32F745/746 microcontroller as a core component as the hardware basis. This achieves a redundancy level HFT = 1 (Hardware Fault Tolerance) and safety level SIL2 in accordance with IEC 61508 and Category 3, Performance Level d (PL d) according to ISO 13849. In these fire protection applications, additional special requirements must be met in order to fulfill the explosion protection guidelines (such as ATEX, IECEx). These include, for example, protection against sparking, the choice of certain materials and compliance with strict safety standards. As the GreCon PROTECTOR is designed to detect and extinguish sparks, it has been tested in accordance with the relevant standards for hazardous areas in accordance with z. IEC 60079 (for explosion protection) and IECEx (ATEX Zone 2). With over 30 years of experience in the field of Ex hardware development, MESCO was able to fully contribute its expertise and prepare the documents for the approvals and defend them before the approval body.

Software Architecture:

The software architecture comprises the following core parts:

- Synchronization and mutual monitoring of the two CPUs

- Self-tests and memory tests

- Secure task switching

- Use of secure black channel communication via UART

Conclusion

The Ranger sets new standards in preventive fire protection technology: it combines modern communication technologies (SPE, PROFINET), high functional safety (SIL2, PL d) and a decentralised, easily scalable system architecture. The close and successful collaboration between Fagus-GreCon and MESCO, as well as the modular, agile development strategy, make the Ranger a future-proof solution for modern fire protection. Thanks to its highly reliable products and many years of experience in fire protection, Fagus-GreCon had all the necessary prerequisites to develop an outstanding, innovative new product. MESCO was able to fully contribute its expertise in hardware and software development for the areas of industrial communication, explosion protection and functional safety. This resulted in a successful development with a deservedly award-winning result!