The following article is adapted from an interview with David Booth, the Accretech SBS software engineer who independently developed and completed the stack implementation described below.

Background and Business Context

Company Overview

Company Overview

Accretech SBS specializes in developing precision process control devices primarily for grinding machines. The company’s product portfolio includes advanced acoustic emission sensors and automated balancing solutions, which necessitate precise, time-critical signal processing. These products are critical for applications such as workpiece touch-off detection and grinding wheel balance automation, where microsecond timing can significantly impact manufacturing quality and efficiency.

Project Genesis

The initial strategy for Accretech SBS’s next-generation product platform, the 6500-series, was to center communication around OPC UA with support for PROFINET planned for the future. A traditional CNC interface was also included to handle simple, time-critical GPIO-type operations. Over time, it became increasingly clear that PROFINET integration was not merely a helpful future addition but a critical requirement for many key customers. This customer-driven necessity initiated a search for a PROFINET implementation that could meet several demanding criteria: it had to offer full control over the codebase for unrestricted development and customer-specific adaptations; maintain cost-effective, unrestrictive licensing; ensure minimal dependency on external support; and allow for complete flexibility in its architecture.

System Architecture

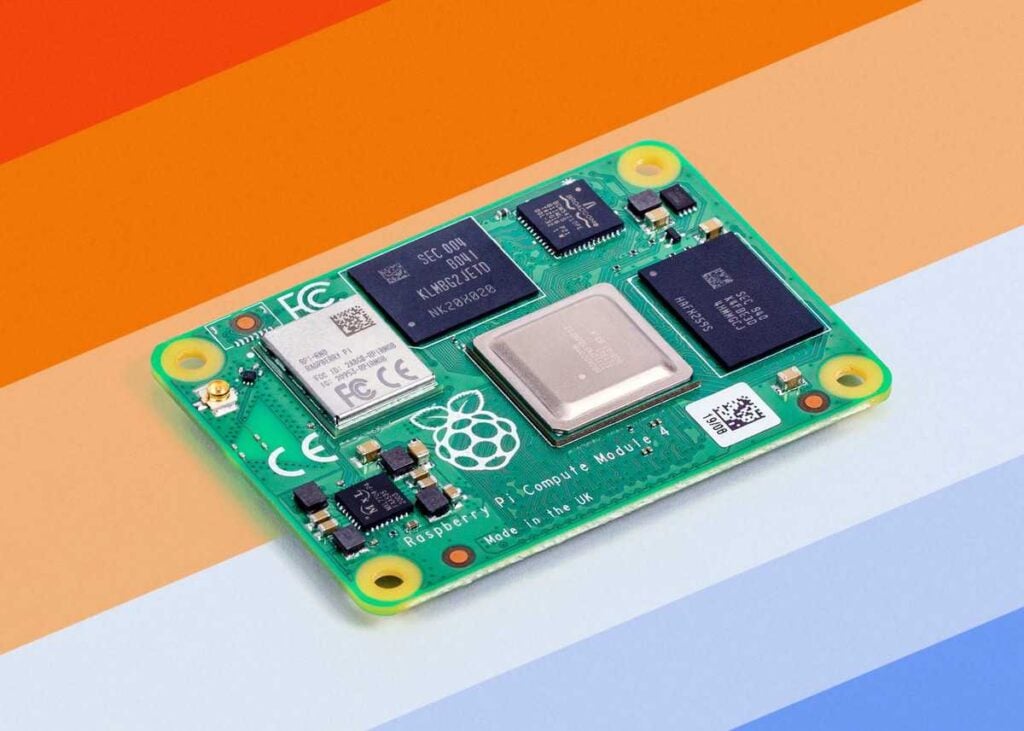

Accretech SBS selected the Raspberry Pi Compute Module 4 (CM4) System-on-Module (SOM) as the hardware platform for its new 6500-series. This provided a robust and well-supported base running Linux with standard networking capabilities. Luckily, the PROFINET Community Stack version 1.0 release included a Raspberry Pi 4 Linux reference implementation, which significantly accelerated the initial development phase.

Solution Selection Process

Solution Selection Process

The Accretech SBS team undertook a thorough evaluation of commercially available PROFINET stacks on the market—of which there are many. The Community Stack was ultimately selected based on several decisive factors. It provided complete internal control over the stack, which can be either a blessing or a curse, depending on an engineering team’s goals and capabilities. For Accretech SBS however, this control was critical for facilitating cross-team collaboration between development groups in the US and Japan, as it eliminated the need for complex, time-consuming technology/stack supplier interactions.

Implementation Journey

Phase 1: Initial Exploration (Week 1)

The PROFINET Community Stack’s Raspberry Pi example accelerated initial development, allowing the team to achieve significant milestones within the first week alone. Successful AR (Application Relationship) establishment, basic signal reading and device control, and a complete proof-of-concept were done rapidly.

Phase 2: Certification Preparation (Months 1-2)

During validation using the PROFINET Automated Real-Time Tester (ART), the team encountered their first major hurdle: a set of test failures, visually represented as a “wall of red.” This required an intense, iterative debugging effort and extensive adjustments to the Linux adaptation layer. Most failures were related to edge-case behaviors, I&M (Identification and Maintenance) record reads, or Linux networking eccentricities.

Phase 3: Advanced Features and Testing (Month 3)

The final implementation phase focused on incorporating features and performance optimization. The team successfully integrated capabilities such as custom Asynchronous Record Handling. Architecturally, the team refined the system by implementing core pinning—dedicating one CPU core exclusively to handling PROFINET communications—and switching to a real-time process scheduler (PREEMPT_RT).

Testing and Certification Process

The decision to utilize the pre-test service offered by the PROFI Interface Center, a certified PI Test Lab in Johnson City, TN, proved invaluable. This service was critical in identifying several key issues prior to formal certification.

Final certification testing successfully surpassed initial expectations. The device achieved full Conformance Class A certification with a Netload Class 3 rating—the highest network load rating. All tests, including those beyond the capabilities of the ART, were passed.

Architectural Benefits and Lessons Learned

The team created a robust design by separating the PROFINET communication into its own program (necessary due to the Community Stack’s requisite 32-bit architecture), which then talks with the main Accretech SBS application using inter-process communication, IPC. This in turn forced a very distinct separation between the PROFINET networking layer and the application logic; changes to the application code have absolutely no effect on the networking layer. Furthermore, this process isolation significantly enhanced overall system stability and made the core pinning process much simpler.

Conclusion

Accretech SBS’s successful implementation of PROFINET using the Community Stack demonstrates that community-supported solutions can meet the basic requirements for inclusion in the expansive PROFINET ecosystem. Can the PROFINET Community Stack also be utilized for expanded feature-sets, higher Conformance Classes, or different architectures? Absolutely, yes: it is capable of the full breadth of PROFINET features. Can this be achieved in a relatively short period or with limited developer resources? Absolutely not. But in the case of Accretech SBS, and for organizations with similar minimal requirements—single-port devices, Conformance Class A, and a willingness to invest in internal expertise—the PROFINET Community Stack presents a viable, cost-effective path to PROFINET certification.