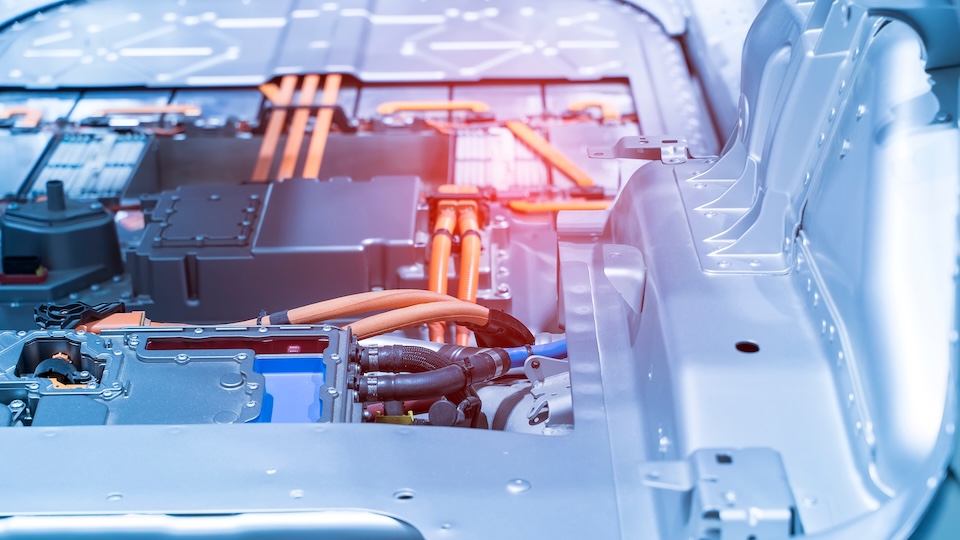

Battery Cell Manufacturing

The global demand for lithium-ion batteries is rising inexorably, presenting manufacturers with enormous challenges. To keep pace with the increasing demand, all process steps – from coating the electrode foils, through calendaring, cutting, stacking, and winding to drying – must be perfectly coordinated.

This requires extreme timing accuracy, real-time communication, and highly precise motion coordination, especially of the axes and drives in the systems. These are ideal tasks for the highly accurate isochronous real-time synchronization method of PROFINET IRT, which enables cyclic real-time transmission with deterministic latency.

PROFINET IRT achieves this by reserving exclusive time slots – up to 50 percent of the communication cycle, depending on the system configuration – which is the basis for highly precise communication. This reservation takes place during the engineering phase, allowing the network load and system performance to be evaluated early on – long before the system is physically implemented. Time synchronization in PROFINET IRT enables a highly accurate, common time base for all participants within a sync domain.

The transmission of setpoint and actual values takes place at a precisely defined time within the update cycle – with a time deviation of less than one microsecond. This enables synchronized motion sequences and minimizes control deviations in demanding automation processes.

Even with high network load and numerous participants – such as cameras, sensors, or servo drives in line topologies – the communication remains completely deterministic. The Dynamic Frame Packing (DFP) function also ensures efficient bandwidth utilization by intelligently combining multiple messages into a single frame – a clear advantage for long lines with many axes.

These are ideal conditions for real-time control of multiple drives with absolute clock synchronization, as required, for example, in the folding process in battery cell manufacturing.

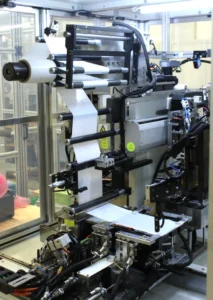

Orchestration of Drives

In battery cell manufacturing, up to 200 axes sometimes need to be orchestrated. This is where the open PROFIdrive communication profile comes into play. The advantage for the user is that they are free to choose their drives independently of the manufacturer, provided they support PROFIdrive. This not only simplifies integration but also the subsequent commissioning of the components. Furthermore, drives with PROFIdrive are essential if the machine is to be simulated – regardless of whether it is a digital twin during commissioning or an executable digital twin to perform a real-time simulation during operation when connected to the physical system.

The Dynamic Servo Control (DSC) function within the PROFIdrive profile enables highly dynamic control of drives in real time and is specifically designed for demanding motion control applications. DSC operates as a closed control loop that is calculated at the fast cycle rate of the speed controller and supplied with setpoints from the position controller cycle. This allows significantly higher gain factors to be achieved in the position controller, resulting in increased stiffness and improved positioning accuracy. A key feature is the support for spline-based feedforward control for speed and torque, which ensures smooth transitions and minimal control deviations, especially with complex motion profiles. The function is therefore a key component for realizing precise, synchronous movements in modern automation systems.

Folded with Utmost Precision

A striking example of the capabilities of this combination is the Z-folding process in battery cell manufacturing. This stacking process plays a key role in battery cell production. A separator film is guided under constant tension by grippers and folded with high precision, alternating with anode and cathode films. This requires the highly dynamic and precise positioning of multiple axes of the grippers, the folding unit, and the feed mechanism. Neither the surfaces nor the edges of the films may be damaged or electrostatically charged during this process.

There are further challenges: A cell stack, which forms the core of the later battery cell, can consist of up to 120 individual layers. Since the goal is to pack more battery capacity into the same space, the trend is towards increasingly thinner and therefore more sensitive separator films. Even today, stacking accuracy is already at ± 200–300 micrometers. This high accuracy is crucial for the quality and lifespan of the battery.

Even the smallest deviations can render the product unusable and result in scrap. This requires a synchronous motion sequence between the handling units and the material feed, for example, when a unit is advanced and lowered simultaneously. The control system requires real-time feedback for position and force feedback.

With cycle times of less than 1 ms and a jitter of less than 1 µs, IRT in combination with PROFIdrive and DSC offers decisive advantages here. This is the only way to precisely maintain motion profiles and keep the films under constant tension during the winding process. At the same time, gripping and folding movements are synchronized and executed without delay. Thanks to real-time control with IRT cycles, the films can be folded with pinpoint accuracy without causing material damage.

Proven in Practice

The interaction of PROFINET IRT and PROFIdrive has already proven itself in real-world projects. This is particularly evident in the steadily increasing number of new drives with PROFINET and PROFIdrive. Through the clever use of PROFINET, production speed and the quality of the manufactured products can be increased in many instances. The stacking machine outlined in this example benefited from the interaction of the highest synchronization accuracy of IRT, the PROFIdrive communication profile with DSC, and the technology objects of the Siemens SIMATIC S7-1500. The quality of the manufactured batteries was improved by 10% compared to other fieldbus systems, while production speed was also increased. The machine is now operating at the limits of its mechanical capabilities.

The interaction of PROFINET IRT and PROFIdrive has already proven itself in real-world projects. This is particularly evident in the steadily increasing number of new drives with PROFINET and PROFIdrive. Through the clever use of PROFINET, production speed and the quality of the manufactured products can be increased in many instances. The stacking machine outlined in this example benefited from the interaction of the highest synchronization accuracy of IRT, the PROFIdrive communication profile with DSC, and the technology objects of the Siemens SIMATIC S7-1500. The quality of the manufactured batteries was improved by 10% compared to other fieldbus systems, while production speed was also increased. The machine is now operating at the limits of its mechanical capabilities.

In addition to the pure production process, other aspects of the machine are also relevant. Plant manufacturers and operators benefit from the use of PROFINET, for example, through simplified machine topologies and integrated safety functions. Safety functions integrated into PROFIdrive, such as “Safe Torque Off” (STO) and “Safety Limited Speed” (SLS), are particularly helpful. And, of course, thanks to the planning function included in the engineering software, PROFINET ensures sufficient bandwidth to send additional data, such as OPC UA or MQTT messages, directly from the machine to the cloud.

Outlook

Quality, throughput, and scalability are key prerequisites for success in the highly competitive market for lithium-ion batteries in battery cell manufacturing. PROFINET IRT not only ensures perfectly coordinated motion sequences at very high speeds within a system but also provides a comprehensive view of the entire production process. This includes, in addition to proven safety concepts, OPC UA with standardized data exchange. Thanks to PROFINET’s openness, production and sensor data can be transmitted to the edge or cloud over the same network – without compromising real-time performance and without burdening the PLC or even requiring reprogramming when new data sources are needed. This paves the way for predictive maintenance, and unplanned downtime becomes a thing of the past.

Mirko Funke,

Mirko Funke,