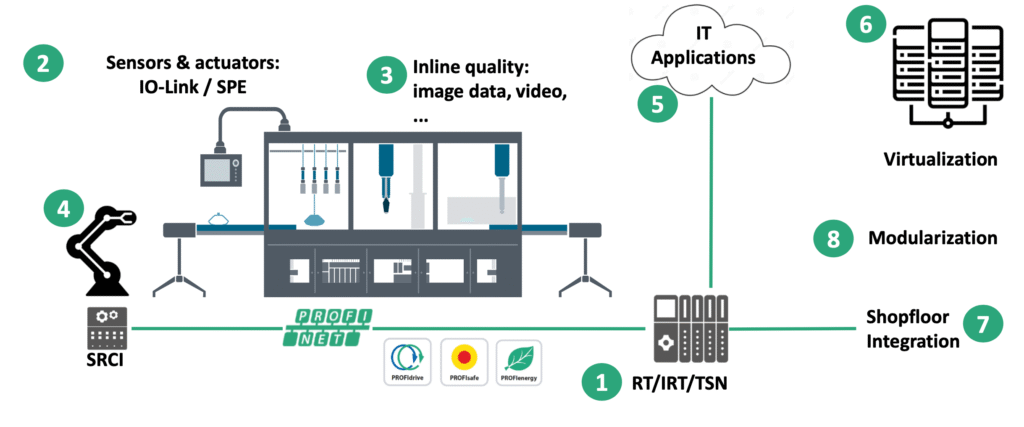

Open Industrial Ethernet Standard Ensures Perfect Integration in Mechanical Engineering Applications

PROFINET is an open Industrial Ethernet standard that meets all the requirements of mechanical engineering through its fast, deterministic real-time communication, as well as integrated safety and diagnostic functions. This enables seamless communication from the field level to the cloud and offers flexibility in designing network topologies and connecting a variety of devices.

Higher Productivity in Wafer Manufacturing

An example of the application of PROFINET is wafer manufacturing at Meyer Burger. By integrating PROFINET, productivity was increased by 50% and downtime minimized. This led to annual savings of around $100,000 USD in material costs.

Plant Efficiency Increased by 25 Percent

The Canadian company Centerline-Seubert was able to increase plant speed by 25% and improve diagnostic efficiency through the introduction of PROFINET. This led to faster troubleshooting and higher plant availability.

Fast Forwarding Reduces Transmission Times

PROFINET offers high-precision communication and fast response times, which are crucial for applications such as robotics and motion control. Mechanisms like Fast Forwarding and Dynamic Frame Packing optimize transmission performance and enable very short cycle times.

Printing Machines: Fit for the Digital Future

Giave Franqueses del Vallés uses PROFINET for its high-end stack flexographic printing machines, which led to a 90% reduction in waste and a 20% reduction in energy consumption.

Lightweight Construction with Integrated Control and Drive Technology

Dieffenbacher developed a production line for lightweight materials that operates 3.5 times faster thanks to PROFINET and enables precise control of infrared emitters.

Servo Drives for Short Cycle Times

Eckel & Sohn mechanical engineering relied on integrated engineering with PROFINET to achieve production rates of over 100,000 units per hour. This was made possible by a new “single-cable servo system” and the distribution of the process across two motion-control CPUs.

Eckel & Sohn mechanical engineering relied on integrated engineering with PROFINET to achieve production rates of over 100,000 units per hour. This was made possible by a new “single-cable servo system” and the distribution of the process across two motion-control CPUs.

Device and Network Diagnostics

![]()

PROFINET offers a flexible diagnostic concept that enables remote access and monitoring of devices in the network. An example is the Siemens Electronics Plant in Amberg, which achieved a defect rate of only eleven defects per million through the integration of PROFINET.

Outlook

PROFINET ensures more flexibility, throughput, and productivity through fast data exchange, high data speed, and deterministic communication. With its profiles for PROFIdrive, PROFIenergy, and PROFIsafe, it saves costs while increasing production and establishing safety and diagnostic functions. The technology is compatible with standard Ethernet technology and offers seamless integration downwards of IO-Link devices and upwards via higher level IT protocols.