PROFINET network diagnostics during commissioning and operation

With the growing use of Industrial Ethernet, in particular PROFINET, in modern production facilities, plant operators are faced with a technology that opens up a host of new possibilities. To fully exploit PROFINET’s advantages, long-established commissioning and operation practices must be reviewed and adapted to the new conditions. General standards and rules for acceptance testing, monitoring and diagnostics of PROFINET networks are currently still being discussed. Softing Industrial Automation has extensive experience in PROFINET technology and offers suitable solutions.

One thing will not change, even with PROFINET: Production facilities must run economically and cost-effectively to ensure competitive production. However, this is only possible if the plant networks work properly and are always available. One of PROFINET’s advantages over previous PROFIBUS installations is that much larger network architectures are possible. Where a typical PROFIBUS network consists of up to 50 devices, PROFINET supports up to 2000 devices and more per network. PROFINET also offers more flexibility, making installations much easier to expand or modify. The integration of additional devices into an existing network is simpler and takes less effort than with PROFIBUS.

Predictive monitoring

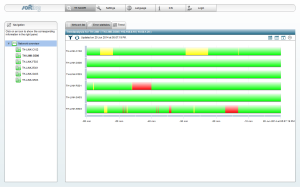

The dynamic development of PROFINET is also reflected in increasing requirements for network availability. Statements like “Once or twice a year, our network breaks down and then our production stands still” or “We’re aware that we’ve got network problems, but we can’t find the cause”, are quite common when talking about today’s PROFIBUS installations. In PROFINET networks with up to 2000 nodes in one network, issues like these have become unacceptable. While error diagnostics in PROFIBUS installations are often only performed sporadically or in the case of failure, it is advisable to preventively and continuously monitor PROFINET networks. This involves keeping an eye on impending failures, changes in network load, and potential error sources. In state-of-the-art production, the facilities must be available 24/7 – similar to search engines such as Google that today are expected to provide access from anywhere in the world at any time.

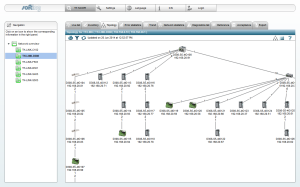

Playing it safe and keeping track of all devices in the network

Users appreciate PROFINET’s flexibility, but for this same reason they should always know which devices are connected to the network and where faults may occur. It can easily happen that more devices are added to the installation than specified in the original configuration. State-of-the-art monitoring software like the TH SCOPE make it possible to query the current topology, the number and status of nodes, the current network load, the firmware versions of devices and the order numbers at any time. The software also detects standard Ethernet devices, such as servers or video cameras, that are not specified in the network configuration, but may often affect network security and stability. This is achieved using IT standards like SNMP, and additional protocol-specific extensions like DCP. Reliability of the communication is another reason why maintenance engineers should always keep track of all the devices in the network, because even regular Ethernet devices can cause a high network load and adversely affect the real-time behavior. State-of-the-art monitoring even goes a step further: In addition to PROFINET and standard Ethernet, the TH SCOPE also monitors other leading Industrial Ethernet standards, such as EtherNet/IP and Modbus TCP, and all that in a single application.

Rapid commissioning and automated acceptance testing

When using Ethernet, there are various tools that facilitate commissioning and acceptance testing, which is quite essential in view of the large number of potential devices in the network. An important step in the commissioning of installations is the automatic determination of the topology, which can be done completely without engineering tools. As many different specialists, from equipment manufacturers to service providers, often work simultaneously on the same network when a plant is being set up, the topology is an ideal way to get an up-to-date overview of all the devices connected to the network. Powerful systems like the TH SCOPE make it easy to automatically generate information about error messages from individual devices, about performance, protocol distribution or inventories of complete device sets, and to document the difference between actual and planned configuration. As a result, they can significantly speed up commissioning and acceptance testing. In the automotive industry, automated diagnostics today are also used to gather further information like network parameters (such as IP address, subnet mask and default gateway) and device parameters. The acquired data can then be compared with the planned configuration created using engineering tools. When using fiber optic cables, additional details are also significant, such as cable lengths, transmission quality and connection quality – in other words, the number of lost packets, deviations from the send cycle, the number of broadcast and multicast frames, etc. All these criteria are then included in the commissioning process.

The right tool for maintenance engineers

Reading out network parameters with suitable tools is only one factor in keeping PROFINET networks up and running. Diagnostics and monitoring tools also have to be easy to use and ready to run immediately when a network problem occurs. Maintenance engineers can then quickly decide whether they can solve the problem themselves or need the services of an IT specialist. Maintenance engineers are usually not IT or network experts who are well-versed in frame analysis and jitter. They need simple-to-use tools that do not require additional engineering. When using high-performance software tools like the TH SCOPE, the network monitors itself, so to speak. If problems occur, the system automatically sends an email or initiates malfunction messages by relay contact, if required, and provides useful troubleshooting tips. The obtained network, line and device diagnostics are available for up to a month after running the diagnostics. Device logs provide valuable information that helps to correct the problem. Diagnostic information is also available centrally and web-based, allowing access from anywhere in the world.

Monitoring pays off

A survey by Softing shows that 76% of users have no experience with commissioning and monitoring tools yet and 37% still use unmanaged devices that do not support diagnostics and topology scans. This means: Consulting and training in diagnostics and monitoring remain on the agenda, particularly because the principles of best practice develop slowly in the field. Softing has recognized this demand and offers independent network services providing comprehensive support for plant operators, system integrators and manufacturers across all industries. As part of a standardized network check, an initial assessment of the condition of a PROFINET network can often be made within ten minutes of installing the devices.

The automotive industry plays a pioneering role in using PROFINET technology and today already applies cutting-edge methods and tools for the commissioning and diagnostics of PROFINET networks – for good reasons: Already today it is possible to cost-effectively monitor PROFINET networks. The additional costs of network monitoring amount to maximum one percent of the device costs, while giving peace of mind that the plant is running. In other words: Investing in network diagnostics has already paid for itself when the availability of the plant through its life cycle is increased by one hour or when the commissioning phase is reduced by one hour.