PROFINET is an established communication standard in industrial automation; in the majority of cases, the development and installation of PROFINET networks presents no problems. If a diagnosis of the PROFINET network is needed, however, many users venture into new territory: For example, the plant commissioning procedure often does not include acceptance testing of the PROFINET networks, and plant operators and maintenance staff are looking for clear best practice guidance on how to monitor PROFINET networks during operation, how to reliably keep them up and running, and how to react quickly and efficiently if problems occur. The reason for this situation lies in the profound changes brought about by the shift from traditional fieldbus systems to PROFINET or, more generally, to TCP/IP-based industrial communication. The first part of this article addressed organizational aspects of these changes. The second part will now discuss technical issues and describe the appropriate PROFINET diagnostic tasks and tools for the different life cycle phases of the network.

Blind Flight or Efficient Maintenance?

Diagnosis of PROFINET Networks

Tasks of PROFINET diagnosis

As detailed in the first part of the article, the tasks – and thus the requirements on the diagnostic tools employed – differ depending on the phase of the plant life cycle and the users involved. These factors determine the required set of diagnostic tools and the necessary functionality.

| Installation | Commissioning | Operation | |

|---|---|---|---|

| Cable test | X | ||

| Acceptance test | X | ||

| Continuous monitoring | X | ||

| Troubleshooting | X | X |

Table 1:

The individual phases of a plant’s life cycle require different diagnostic functionalities for PROFINET networks.

Cable validation

A key task in the installation phase is to ensure correct cabling. Testing every single cable that is used would involve too much effort, however. Therefore the focus is on checking all important network cables, which is primarily cables that are used as the backbone and that are permanently integrated and difficult to replace, as well as custom cables. Standard cables can generally be used without special verification. A useful tool for the validation and certification of Ethernet cabling, e.g. during acceptance testing, is the WireXpert 500 IE product from Softing Industrial Automation.

Support during commissioning

Once installation is complete, the next phase in the plant’s life cycle is the commissioning phase. Here the diagnostic tasks are aimed at detecting general configuration and communication faults in the installed PROFINET network, and documenting the network and the acceptance test in order to minimize the residual risk of network failure during operation of the plant. The configuration faults to be detected include, for example, device names that are used in the controller, but not assigned to any device in the network. During acceptance testing, documents are issued that detail the current characteristics of the PROFINET installation and serve as evidence and as a basis for future comparisons. One of these documents is the network topology representing the nodes connected to the network. Selectable filter settings allow adjustment of the size, layout and level of detail (see Figure 1). Another document in this phase is the inventory list which contains a complete, detailed list of all devices. An acceptance test report automatically summarizes all the individual results of the acceptance test. The last step in this phase is the reference measurement with a record of the network status that was rated as “good” in the acceptance test. This record provides a basis for future comparison with the current network status during operation of the plant, and is a useful aid in troubleshooting if network problems occur.

Once installation is complete, the next phase in the plant’s life cycle is the commissioning phase. Here the diagnostic tasks are aimed at detecting general configuration and communication faults in the installed PROFINET network, and documenting the network and the acceptance test in order to minimize the residual risk of network failure during operation of the plant. The configuration faults to be detected include, for example, device names that are used in the controller, but not assigned to any device in the network. During acceptance testing, documents are issued that detail the current characteristics of the PROFINET installation and serve as evidence and as a basis for future comparisons. One of these documents is the network topology representing the nodes connected to the network. Selectable filter settings allow adjustment of the size, layout and level of detail (see Figure 1). Another document in this phase is the inventory list which contains a complete, detailed list of all devices. An acceptance test report automatically summarizes all the individual results of the acceptance test. The last step in this phase is the reference measurement with a record of the network status that was rated as “good” in the acceptance test. This record provides a basis for future comparison with the current network status during operation of the plant, and is a useful aid in troubleshooting if network problems occur.

Depending on the situation, it may also be advisable to run a network load test as part of commissioning. This test examines the behavior of the installed network (utilization, number of frame errors, etc.) under load and differs from load or stress tests for single devices, in which the robustness and the conformity with device standards are typically assessed in a laboratory environment.

Network diagnostics during operation

While the plant is running, plant operators need an overview of the plant-wide status. Diagnostics in this phase are aimed in particular at ensuring a high plant productivity and avoiding costly downtime. The focus is on the continuous monitoring of the PROFINET communication and on the efficient support of users in the case of emerging problems or network failure. During continuous monitoring, key characteristics such as the current network load and the number of error packets are monitored. In this way, negative influences on the PROFINET data exchange can be eliminated, for example, when replacing an Ethernet device or expanding a decentralized I/O system. If a specified limit value is exceeded on the monitored network, the user is automatically notified.

For many maintenance tasks and for finding typical faults that are common during operation, users do not need special IT knowledge. The employed tools provide the necessary functionality, such as an aggregated view of the overall network, network communication statistics, and maintenance and troubleshooting advice in plain text. The tools also detect cable problems, device drop-outs and broken connections. An example of fault statistics can be seen in Figure 2.

For many maintenance tasks and for finding typical faults that are common during operation, users do not need special IT knowledge. The employed tools provide the necessary functionality, such as an aggregated view of the overall network, network communication statistics, and maintenance and troubleshooting advice in plain text. The tools also detect cable problems, device drop-outs and broken connections. An example of fault statistics can be seen in Figure 2.

During plant operation, users are also faced with “network management” tasks. A typical task, for example, is to update the firmware in all devices of a particular device type. Using suitable tools, the users can quickly see at a glance if all devices are discovered after the update and if they have been updated to the correct firmware version.

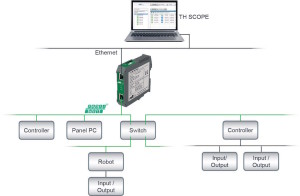

The ke y components for acceptance testing and network diagnostics in this phase are the TH LINK PROFINET and TH SCOPE products from Softing Industrial Automation (see Figure 3). Designed specifically for maintenance staff and plant operators, these tools can be used without in-depth IT or Ethernet knowledge. The TH LINK PROFINET gateway provides access to the PROFINET network independently from the controller or control room. The gateway can be integrated at any time, without interfering with the operation of existing installations. It requires neither configuration nor development work. The TH SCOPE software application is used for the monitoring and maintenance of the PROFINET networks used. It processes the data acquired by the TH LINK PROFINET and displays it in the form of graphs. This solution enables local and remote access, and also provides a browser interface. Third-party tools can be integrated into the diagnostic solution through the SNMP or OPC standards. The BC-200-ETH Industrial Ethernet Tester can be used additionally in order to perform network load tests.

y components for acceptance testing and network diagnostics in this phase are the TH LINK PROFINET and TH SCOPE products from Softing Industrial Automation (see Figure 3). Designed specifically for maintenance staff and plant operators, these tools can be used without in-depth IT or Ethernet knowledge. The TH LINK PROFINET gateway provides access to the PROFINET network independently from the controller or control room. The gateway can be integrated at any time, without interfering with the operation of existing installations. It requires neither configuration nor development work. The TH SCOPE software application is used for the monitoring and maintenance of the PROFINET networks used. It processes the data acquired by the TH LINK PROFINET and displays it in the form of graphs. This solution enables local and remote access, and also provides a browser interface. Third-party tools can be integrated into the diagnostic solution through the SNMP or OPC standards. The BC-200-ETH Industrial Ethernet Tester can be used additionally in order to perform network load tests.

Troubleshooting complex problems

During commissioning or operation of the plant complex faults, such as a large number of error frames on a particular port, may occur without apparent cause. Troubleshooting these problems usually requires in-depth knowledge and expertise in communication and information technology, as well as special tools for locating, identifying and correcting the fault. In many cases, for example, users may need to perform a frame analysis of the communication. This can be done with additional tools, such as temporary taps in combination with the Wireshark software.

Summary

The use of TCP/IP-based communication changes the character of industrial networks. The comprehensive plant-wide planning of the diagnostic tasks to be performed provides key benefits to PROFINET users looking to minimize the failure risk of their production plant and increase the efficiency of their maintenance work. A thorough acceptance test for the PROFINET network provides a sound basis for the future smooth operation of the plant. Softing offers a complete portfolio of products for PROFINET network diagnostics, ranging from installation and network acceptance testing to continuous network monitoring during plant operation.