Renovation of the blast furnace at ArcelorMittal Méditerranée

A digital giant in a human affair

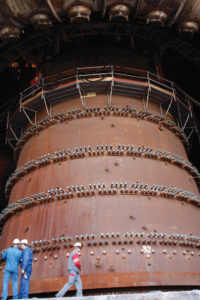

In response to exponential market demand, the annual production capacity at the ArcelorMittal site in Fos-sur-Mer, France, is due to rise from 4.6 to 5.3 million tons of steel. One of the key projects designed to help meet this objective was the refurbishment of blast furnace number 1.

The preservation of this colossal piece of production equipment notably called on new measuring instrumentation technologies and the standardized PROFIBUS field  network to replace a large proportion of the analog signals. The blast furnace is currently the first digital blast furnace in the world. Endress+Hauser assumed responsibility for the efficiency of the project for the instrumentation lot.

network to replace a large proportion of the analog signals. The blast furnace is currently the first digital blast furnace in the world. Endress+Hauser assumed responsibility for the efficiency of the project for the instrumentation lot.

The giant is over 80 meters tall with a capacity of 3,000 cubic meters. The temperature inside the 11 meter diameter crucible is +2,000 °C. Controlling this process digitally means exposing the automation system and instrumentation to extreme conditions.

Endress+Hauser was involved throughout this huge project, from planning through to commissioning.

A solution to the client’s problems

“The success of the refurbishment of the blast furnace firstly depended on a very productive design phase. After that, we simply had to get the best companies in their respective fields on board” explains Philippe Divol, Project Manager at ArcelorMittal.  “Endress+Hauser was able to answer all our questions about the new configuration of the instrumentation in the fieldbus” adds Alphonse Fabiani, Instrumentation Engineer at ArcelorMittal.

“Endress+Hauser was able to answer all our questions about the new configuration of the instrumentation in the fieldbus” adds Alphonse Fabiani, Instrumentation Engineer at ArcelorMittal.

Long-standing partners, ArcelorMittal and Endress+Hauser worked together. The overall supply of measuring instruments fulfilled all aspects of the prerequisites, but ArcelorMittal also stood to benefit from the expertise and support provided by the Endress+Hauser teams: experienced professionals in engineering for process automation and project management.

Attentive and jointly liable for the outcome

To satisfy the quality, safety and efficiency requirements when commissioning the instrumentation and the digital network, Endress+Hauser decided to create and enter into a joint venture with two other well known companies, SNEF and Cegelec. Objective of the joint venture was to consider, supply, install and commission the entire instrumentation lot within set time-frames. Teamwork and reciprocal technical or industrial exchanges were at the heart of this consortium. “We needed solutions, not people who would trade accusations of responsibility for mistakes. As representative of the joint venture, Endress+Hauser assumed joint liability for the outcome of the partnership,” clarifies Philippe Divol. André Amar, ArcelorMittal Account Manager at Endress+Hauser for more than 26 years, ensured that the changes, sometimes requested by the client at short notice, were implemented quickly. “You could say that Endress+Hauser demonstrated great efficiency and flexibility,” says Philippe Divol.

For genuine support

The specialist technicians at Endress+Hauser commissioned 1,100 sensors directly on the blast furnace and supervised 700 others in the peripheral workshops, such as the gas cleaning system and slag treatment, all connected by the digital network. More than 400 sensors on the blast furnace are connected via PROFIBUS. “In order to reduce the length of intervention and by extension the exposure to risks, all the measuring instruments were prepared and preset in our workshops” adds Luc Reibel, Project Manager at Endress+Hauser. The instruments benefit from long-term service contracts. For its operators, the park is easier to manage thanks to dedicated software such as FieldCare and W@M – Life Cycle Management, a unique tool that provides access to all manufacturer data and the log of interventions on the devices.

For maximum efficiency of the production equipment

The service life of the refractory lining in a blast furnace is 20 years, and over the next 20 years the Mediterranean giant will be operating at full capacity. In fact, Alphonse Fabiani is hoping to draw on all the options made available by the devices connected to PROFIBUS. “It will be possible to perform settings and diagnostics remotely. We will have a predictive – rather than a curative – approach to maintenance. We are handing down future-oriented technology to generations of steelworkers to come.”

Many people, one team, one giant

This project is a good example of expertise and teamwork combining to provide a service: after 95 days of downtime, blast furnace number 1 was given a new lease on life. Building on this success, Endress+Hauser has partnered with ArcelorMittal once again to renovate blast furnace number 2 at the Fos-sur-Mer site.

Endress+Hauser services

- Endress+Hauser as Main Instrument Vendor (MIV)

- Project management

- Implementation of platform tests (field network design, PROFIBUS compliance reports)

- Design and provision of measuring instruments (flow, pressure, temperature), namely 1800 instruments installed and commissioned and over 60 km of cables laid

- Fieldbus integration

- Field network verification

- Commissioning

- Training

- Consignment stock

The renovation project in numbers (all trades)

- 450 000 hours of preparation

- 550 000 hours of intervention on site

- 1 million working hours

- 95 days of downtime

- Around a hundred companies

- 800 people working every day