Process protection by means of Asset Management with PROFINET

As the growth of PROFINET continues, new customer requirements for additional Asset Management functions have been incorporated. Added is the ability to record assets to make maintenance and operation easier despite increasing complexity of processes and related machines.

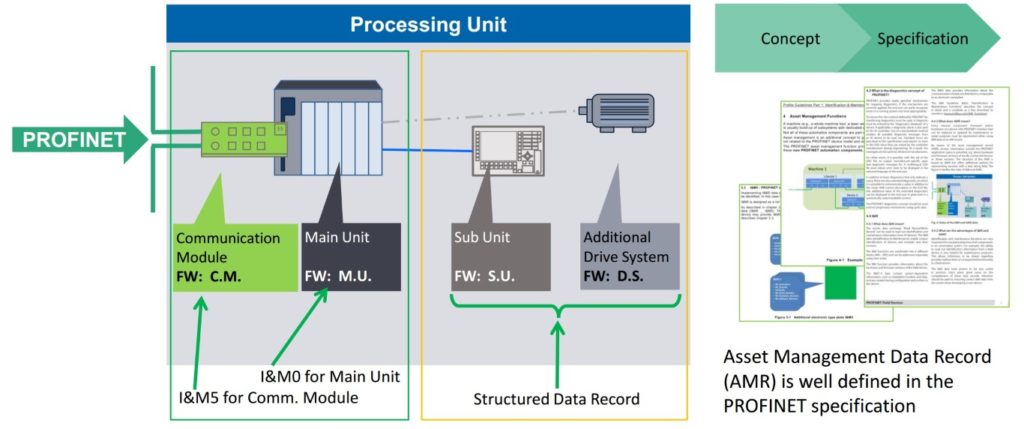

After a precise clarification of the requirements with users, the PROFINET specification has been expanded by the Asset Management Record function after a concept phase. A digital fingerprint of the plant is now available. Together with the Identification & Maintenance data already proven for PROFINET devices, an extensive registration of devices and machines is possible, even if they are not part of the PROFINET environment. A simple acquisition of hardware and firmware statuses, installation locations, etc. is necessary in order to confirm a suitable device installation during startup or upgrading. In addition, the respectively used firmware drivers can be checked in this way so that the necessary and approved assets are used for the respective work process. On account of the open TCP/IP communication, this data is not only accessible by a PLC, but additional tools also can access the data without additional measures. These two aspects of Industrie 4.0 – the precise data specification and the simple access from the outside – are thus implemented already today in Asset Management with PROFINET. Qualified machine-readable data only, which are defined cross-vendor, lead to reduced efforts during asset management and to a concrete benefit of Industrie 4.0 applications.

Details on the functions are described in the PROFINET specification as well as in the known developer documents, such as in the “PROFINET Field Devices Recommendations for Design and Implementation.” These documents are available for free download by members at www.profinet.com.