The Importance of Open Standards

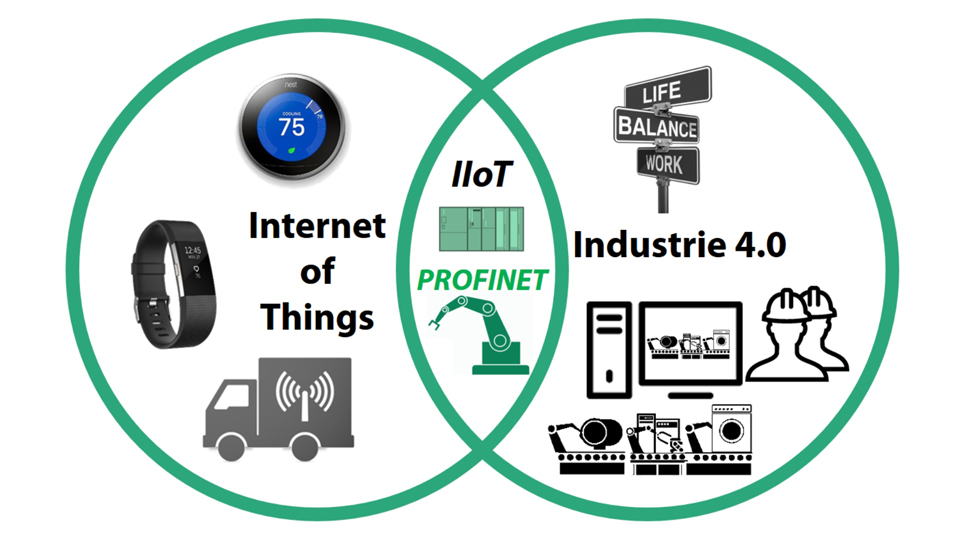

As the data from factories scales exponentially, the ability to access that data transparently becomes critical. If we want the Industrial Internet of Things to truly be a game changer for the manufacturing industry, open standards will be a major enabler of that transformation.