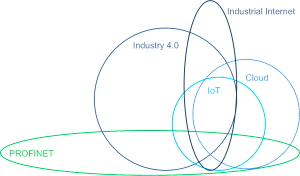

The Industrial Internet of Things (IIoT) has become a hot topic for many in our industry over the past year. Whether you call it Industry 4.0 or Internet of Things or Industrial Internet, if you can’t get the data there is no IIoT. That data needs to be acquired: reliably, in real-time, with alarms, with diagnostic information, and from legacy buses. Recently discussions have evolved to describe how PROFINET is a direct enabler for the IIoT. It is important to note that while there has been a focus on this general concept for many years now, “Internet of Things” just happens to be the most recent of those names and has taken hold.

If you can’t get the data there is no IIoT.

Background

In general, the Internet of Things refers to the collection of smart objects (as opposed to people) connected to the Internet. It can be broken down into three realms:

In general, the Internet of Things refers to the collection of smart objects (as opposed to people) connected to the Internet. It can be broken down into three realms:

- Consumer

- Commercial

- Industrial

The “Consumer” market consists of things that we interact with in our daily lives: smartphones, cars, refrigerators (yes, even smart refrigerators). Some of these things have yet join the “Internet of Things” and some already have. The “Commercial” market consists of things we don’t necessarily see, but affect our daily lives inherently: smart HVAC units, smart thermometers, light bulbs, alarm systems, and buildings. Finally, in the “Industrial” market things are assets from something as small as an I/O block or sensor to a PLC and all the way up to an entire machine, turbine, production line, or factory. PROFINET concerns itself with the latter of these, connecting machines, motors, sensors, and actuators in factories and processing plants.

In Industry

The IoT concept is being investigated by industrial companies for the extended abilities to monitor and analyze assets. They’re moving and collecting data as a way to gain a competitive advantage. If this results in even a 1% increase in efficiency, it can yield huge gains in high value assets. Companies are connecting historians, the Cloud, Big Data, and analytics packages to their machines.

The IoT concept is being investigated by industrial companies for the extended abilities to monitor and analyze assets. They’re moving and collecting data as a way to gain a competitive advantage. If this results in even a 1% increase in efficiency, it can yield huge gains in high value assets. Companies are connecting historians, the Cloud, Big Data, and analytics packages to their machines.

But what sets PROFINET apart in the Internet of Things? It has:

- A real-time component for capable industrial control

- Comprehensive diagnostics (video) “baked into” the protocol

All built on standard Ethernet. The real-time component of PROFINET means messages at the device level get there in a deterministic fashion. In other words, the ‘control’ aspect can be taken for granted, and the diagnostics allow for insight down to the device, module, or even channel level.

For example, this data can be collected in a PLC or DCS controller. The controller then buffers the data. This information is then accessed easily with proprietary methods or open standards like OPC-UA. But it all starts with data. PROFINET uniquely provides data access reliably, in real-time, with alarms, rich diagnostic information, and from legacy buses.