Tire manufacturing machinery in general, and tire curing presses in particular, incorporate numerous sensors and indicators that contribute to machine efficiency. As an example, tire curing presses often use magnetostrictive linear position sensors for feedback and control of mold open/close. Overwhelmingly, sensors that provide an analog, 4-20 mA signal are used. But maybe there’s a better alternative to typical analog feedback.

As an example, tire curing presses often use magnetostrictive linear position sensors for feedback and control of mold open/close. Overwhelmingly, sensors that provide an analog, 4-20 mA signal are used. But maybe there’s a better alternative to typical analog feedback.

Migration away from typical analog sensor signals to network-capable IO-Link interfaces makes a great deal of sense in many areas of application.

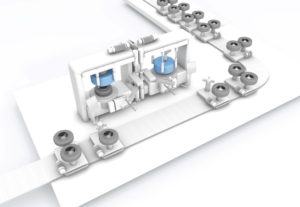

In a tire manufacturing operation, there are typically numerous, essentially identical curing presses, lined up in a row, all doing essentially the same job. Each press uses multiple analog position sensors and each needs to be connected to the press control system. As with pretty much any analog device, the use of individual shielded cables is critical. Individual shielded cables for every sensor is a costly and time-consuming proposition. An Engineering Manager at a machine builder said recently that wiring each press requires around 300 man hours, a significant portion of which is spent on sensor and indicator wiring.

Which brings us to IO-Link. Replacing those analog sensors with IO-Link sensors, allows feedback signals from multiple  machines to be consolidated into single cable runs and connected to the Profinet network. The benefits of such an approach are numerous:

machines to be consolidated into single cable runs and connected to the Profinet network. The benefits of such an approach are numerous:

- Wiring is simple and much more economical

- Eliminates need for shielded sensor cables

- Integrated diagnostics allow remote machine status monitoring

- Reduces more expensive analog IO on the controller side

- Over-the-network configuration and the ability to store those configurations reduces setup time

And, by the way, the IO-Link story doesn’t end with position sensors. The ever-growing list of IO-Link enabled sensors and indicators allows the benefits to be rolled into many areas of machine automation, such as:

- Intelligent IO-Link power supplies with HeartBeat technology that monitor their own “health” and report it back over the network (think Predictive Maintenance)

- Highly-configurable IO-Link stack light alternatives that can be set up to display a number of machine and process condition states

- IO blocks, memory modules, pressure sensors, discrete (on/off) sensors of all type, and more

Article provided by Balluff from their SensorTech blog.