There is often some confusion when engineers begin to use Human Machine Interfaces (HMIs) and PROFINET, so we will explain how HMIs are typically used in PROFINET systems and describe the types of HMIs and application protocols available.

First off, let’s start with a description of what an HMI is:

First off, let’s start with a description of what an HMI is:

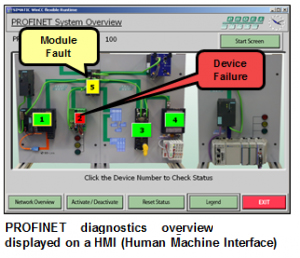

A Human Machine Interface (HMI) or sometimes called Operator Interface is a device used in automation environments which provides graphics-based visualization for both monitoring and control for a human operator to interface to a machine. Oftentimes, on PROFINET systems, this is a device connected to the network which usually communicates to a Programmable Logic Controller (PLC), Programmable Automation Controller (PAC), or Distributed Control System (DCS). An HMI can be used to read or write process information to these systems or to receive notifications and diagnostics / alarm messages in case a problem arises.

In modern systems, HMIs have become even more ubiquitous and can be implemented via an external node with a built in display usually ranging from 4” to 20” screen size (operator panel / interface), a PC with HMI software loaded, or even a mobile device such as a tablet or smartphone with a special HMI app. It should be noted that HMIs can be wired or wireless on PROFINET systems allowing mobile functionality. The advantage of a mobile device is that it can be right beside the operator at all times. Some PROFINET HMIs might even have an e-stop button built in (for instance as part of a PROFIsafe application) to stop the machine in case a safety issue occurs.

As the need for more information arises and the use of analytics and machine tracking are employed, HMIs are as important as ever and their role is even expanding. HMIs may not just be monitoring a device or a single machine now; they might be monitoring the entire process or multiple machines in conjunction with a Supervisory Control And Data Acquisition system – SCADA. We even see HMIs embedded in PLCs, drives, network components, and other devices to offer easy device management and process monitoring. Also, cloud based monitoring systems with analytics and diagnostic reporting on the overall process can be found.

Many questions may arise when using HMIs on a PROFINET system such as “What protocol(s) are the HMIs typically using on a PROFINET system?”, “How can I use  them in my applications?”, and “How can you best design HMIs into a system?”

them in my applications?”, and “How can you best design HMIs into a system?”

The good news is that there is no need to worry. HMIs work seamlessly on PROFINET systems because PROFINET is an open network, so any Ethernet based protocol can be used on your HMIs whether it’s PROFINET real time (RT) or TCP/IP, but there may be reasons to choose one type or another depending on your application requirements. And all application scenarios are well covered by vendors today.