Whether it’s called Industrie 4.0 or the Industrial Internet of Things – digitalization has long since encompassed all industry sectors and brings with it new business opportunities, but also new challenges. Only by consistently taking advantage of all available data is it possible to exploit all the savings potential and open up new possibilities. That applies to the process industry in particular.

Operational excellence in production requires running production at an optimal level and permanently ensuring the availability of the plant. Furthermore, devices in the field are expected to transmit status signals for maintenance and diagnosis and parameter data, in addition to the actual measurement and control values, in order to allow comprehensive plant asset management. Even though the corresponding NAMUR Recommendation 129 is from 2009, plant asset management is far from standard even today. Modern Ethernet-based fieldbus systems come into play as an enabler.

The increasingly demanding communication requirements can be met by using “intelligent” field devices (scales, analysis devices, smart transmitters) in which partially configurable, partially parameterizable information processing provides better quality measurement signals within the devices and relieves the burden on the following signal process in the controllers of the process control system. Unlike with the analog standard signal (4 – 20 mA), with digital signal transfer it is possible to transfer higher resolution signals and verify the correctness of transferred data. As a general rule, digital transfer occurs with no loss of precision. If we wanted to transfer the additionally available status signals conventionally, the immense wiring effort that is already necessary today would reach unrealistic proportions. In a press release from December 2016, NAMUR (the User Association of Automation Technology in Process Industries) also emphasizes once again that the transition to fieldbus systems will be the only opportunity to face this problem.

Requirements on an Ethernet-Based Process Fieldbus

Users in the process industry have very specific ideas about what fieldbus systems must achieve. One of the basic requirements that was already discussed at the 2012 NAMUR Annual General Meeting is a “plug and play” concept for field devices. The basic idea is to make field device replacement semi-automatic. The installation location must be assigned manually to the new device, but the rest should occur automatically.

However, process automation still places many additional requirements on automation solutions. The plants are complex and often constructed of multiple sub-systems; they are large and usually extensive and have a lifespan of 15 to 40 years. The production processes must run fault-free and without any interruptions (24 hours a day, 365 days a year), sometimes over several years. This requires a flexible communication topology, robust connection technology, and redundancy concepts for critical functions. Another special requirement of the process industry (including chemical, petrochemical, oil & gas) is operation in potentially explosive areas.

Modifications and extensions are frequently made throughout the lifecycle of the plant, and the configuration of the automation changes correspondingly. The communication protocols used in the automation must meet these requirements.

PROFINET for the Process Industry

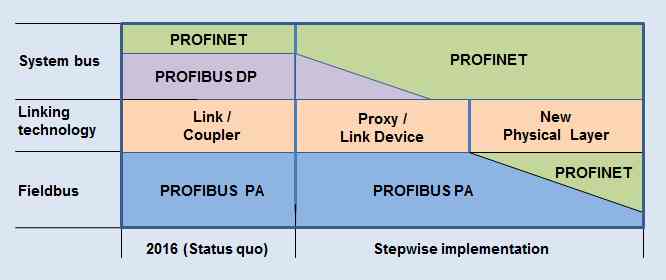

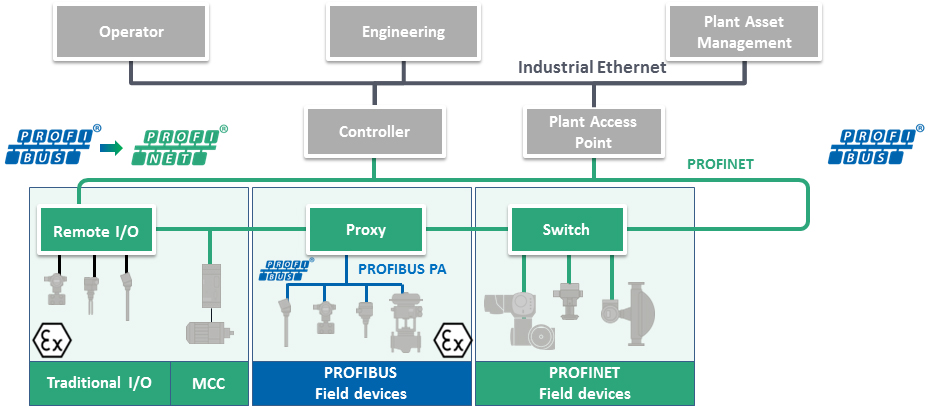

PROFINET can be used in process technology plants in the short term. The corresponding functions and products are already available or have been announced. PROFINET provides special functions for the requirements of process automation. Scalable redundancy solutions corresponding to the automation requirements that are made and changing the configuration at run time are new elementary functions that will find their way into the automation components. Lower-level systems can be integrated seamlessly into the automation system. This provides investment protection for existing plants and instrumentation, e.g. with PROFIBUS PA.

PROFIBUS PA is the proven fieldbus from PI (PROFIBUS & PROFINET International) for the process industry. It allows extended cabling, explosion protection, and digital integration of the field instrumentation into control and asset management systems and power supply to the field devices through the bus via the “Manchester-Encoded Bus Powered” (MBP) physical interface according to IEC 61158-2.

Segments of networked PA field devices (devices with an implemented PA profile) can be connected via coupling components (link, coupler, proxy) to PROFIBUS DP or PROFINET. Thus PROFIBUS PA remains the future-proof key technology for the process industry with guaranteed future compliance protection.

PROFINET: Proven in Practice in Industrial Applications

PROFINET is already an established industry standard and is used in the so-called hybrid industries in addition to factory automation. Filling plants or mixing applications can already be automated with PROFINET without difficulty. Frequency converters, automation systems, and decentralized peripherals with Ethernet derivatives are available. The advantages arise over the entire lifecycle of a plant.