The Challenge

Electric Rubber Tired Gantry Cranes (E-RTG) are highly sophisticated machines, operating in container terminals around the world. Instead of being restricted to moving on a track the E-RTG crane is able to straddle multiple lanes on its rubber wheels, securing maximum mobility and speed. However, the crane’s flexibility has a downside: how do you provide a stable supply of power? As long as it moves along container corridors the crane can be powered via conductor lines or motorized cable reels. But outside the corridors, it has to rely on “onboard” power.

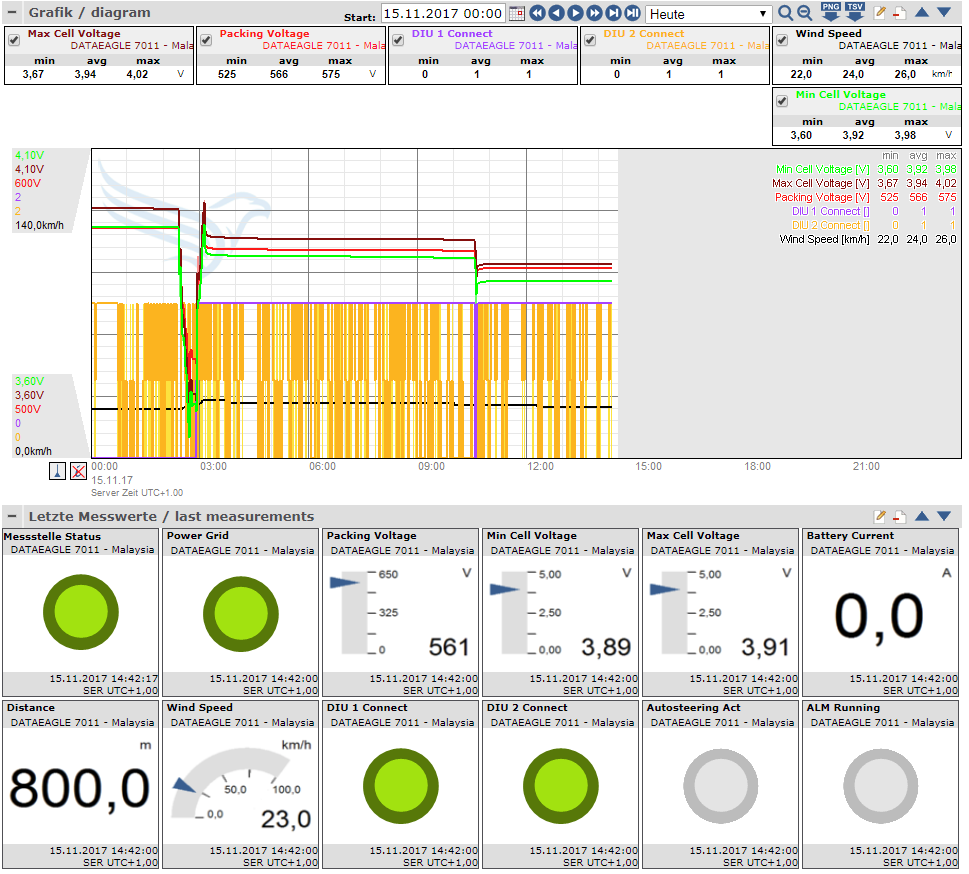

So far, diesel generators have done the job, but now container terminal operators are looking for more environmentally friendly and cost-effective alternatives. To meet this demand, Conductix-Wampfler has designed hi-tech battery systems mounted in a container directly on the crane. These battery systems are sophisticated devices packed with hi-tech components that need to be monitored by sensors to secure flawless operation and maximum uptime. In this case, PROFINET is the industrial network of choice. Since the cranes are deployed in container terminals around the world, remote monitoring should be possible from a central location. In order to roll out such a remote monitoring solution on a global scale, a global connectivity infrastructure is required: the cranes being on the edge of the network and a web portal in its center, located with the operator monitoring the equipment.

Wireless Solution

PROFINET, in combination with an industrial radio-based IoT Edge Gateway from Schildknecht AG, managed to successfully implement the solution for this demanding application. On the input side, the gateway receives up to eight sensor signals via PROFINET. On the output side there is a mobile radio connected with a 2G, 3G or 4G cellular network. Some of the problems to be solved came from the cranes themselves: they are continuously in motion, and on top of that, the gateways in the battery systems are surrounded by metal. Therefore high-performance radio communication technology is required to secure dependable and stable data transfer.

The I4.0 Approach

Conductix-Wampfler has equipped a number of E-RTG crane battery systems with the remote monitoring technology developed in collaboration with Schildknecht, including PROFINET to cloud communication. Evaluating the results, both partners are confident that they have succeeded in securing a stable level of global data transfer, even in harsh environments. Also, the portal presents measurement data in an accessible way, giving monitoring personnel a quick and intuitive overview of the condition of the globally scattered machinery; the project has evolved into a promising IIoT business model.