Giant tank farms are not only just in the oil and gas industry. More and more extensive tank farms are coming into existence with the flourishing palm oil industry in Southeast Asia. In Indonesia, a new project has been implemented by the system integrator DNR Process Solutions which uses its tank farm management system. DNR chose to directly integrate the PROFIBUS PA segments via Ethernet when it came to selecting an installation that would be up to Industry 4.0. The gateways pnGate PA from Softing were the choice for the well-known system integrator – and the experience was outstanding.

Palm Oil Production

Palm oil volume produced worldwide has been steadily increasing over recent years – from about 17 million tons a year in 1996 to a good 72 million tons in 2018. Over 80 percent of that amount originates in Indonesia and Malaysia. Indonesia has tripled its production since 2002. Its world market share is now 51.1%. Palm oil is one of the major agricultural crops, behind rice, cassava, and corn, and is considered an important export product. The majority of palm oil fruits cultivated there are also pressed and processed locally through refining. The refined palm oil is stored on site in large tank farms, comprising many large tanks, before being transported via ship or tankers for further processing.

Searching for a Solution

One of the world’s leading palm oil producers in Indonesia works extremely efficiently and with high productivity thanks to the plant’s high degree of automation, among other things. This also includes downstream processes. In particular, it strives for seamless integration of the sensor and actuator technology into the higher-level control and management level within one tank farm. This allows integrated inventory management, monitoring of field devices facilitating maintenance scheduling and gives the possibility for remote monitoring for an IIoT solution.

One of the world’s leading palm oil producers in Indonesia works extremely efficiently and with high productivity thanks to the plant’s high degree of automation, among other things. This also includes downstream processes. In particular, it strives for seamless integration of the sensor and actuator technology into the higher-level control and management level within one tank farm. This allows integrated inventory management, monitoring of field devices facilitating maintenance scheduling and gives the possibility for remote monitoring for an IIoT solution.

Tank Farm Instrumentation over PROFIBUS PA

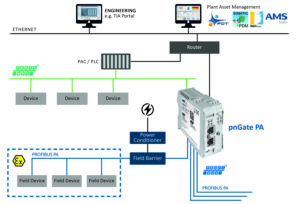

The vessels in the tank farm, which consists of six groups of six tanks each, are each instrumented with a radar level gauge, a level limit switch and a multipoint thermometer. By using the reference temperature, the current volume of the stored oil quantity can be determined from the current level. Temperatures and levels are transmitted via PROFIBUS PA. Usually, these are transmitted to the higher-level process control with the aid of a DP/PA coupler and then converted to a PROFINET signal which can be a relatively expensive undertaking. Applications based on PROFIBUS DP do not fully meet the high requirements of digitalization: for example, in regard to suitability in a Zone 1 area.

In mid-2018, DNR turned to its component supplier Link Vue Systems in search of an alternative for further digitalization and Industry 4.0 customization. “We wanted to find the best and most up-to-date data communication technology for our customer,” says Prafullit Sharma, CTO of DNR. Transmission consistency needed to be ensured via standardized interfaces in the future. Vidyut Gandhi of Link Vue had a suggestion on how to switch to future-proof technology. “With the relatively new pnGate PA gateway from the German automation provider Softing Industrial Automation, PROFIBUS PA segments can be directly integrated into PROFINET systems,” said Gandhi. This gateway is one of the few solutions on the market that is suitable for eliminating the PROFIBUS DP level and integrating it directly on Ethernet instead.

PROFINET as the Primary Network

“The main r eason for choosing a PROFIBUS PA to PROFINET gateway was that it allowed us to create a seamlessly integrated solution,” says Sharma. In addition, the system integrator had to take into account the need for integrating not only the PA devices but also the conventionally wired level switches, pumps, and agitators. Their I/O cards were based on the Siemens ET200 SP PROFINET I/O modules. Sharma says: “That’s why it was imperative to implement PROFINET as the main network.”

eason for choosing a PROFIBUS PA to PROFINET gateway was that it allowed us to create a seamlessly integrated solution,” says Sharma. In addition, the system integrator had to take into account the need for integrating not only the PA devices but also the conventionally wired level switches, pumps, and agitators. Their I/O cards were based on the Siemens ET200 SP PROFINET I/O modules. Sharma says: “That’s why it was imperative to implement PROFINET as the main network.”

Since DNR had extensive experience with PROFIBUS – including one of the world’s largest PROFIBUS projects with around 10,000 nodes – the integration hurdles were negligible. There was one small challenge when integrating the PLC but DNR mastered it with the device manufacturer’s support. The configuration existing on the PA side can be transferred almost intuitively to the control project with the help of a special web server. The big advantage: For the operator, the gateway is transparent, so to speak. The PA devices continue to be “visible” and the operator can assign respective process and diagnostic data to each of them and access them. Ultimately, DNR was able to complete the implementation for all of the tanks.

A Futureproof Solution

“The integrated and unified architecture that we were able to achieve with pnGate PA is the most important benefit for the tank farm operator,” Sharma explains.

The tank farm inventory management system reliably receives up-to-date data from the field and in a very short period of time – a great advantage considering the vast size of the palm oil producer tank farms and all of their numerous field devices. The integrated platform also handles reporting. All in all, DNR can offer the palm oil producer the conditions needed for extensive digitalization of its processes and create the prerequisites for Industry 4.0.