Around this time last year, we wrote an article about industrial networking trends for 2019. Highlighted were three themes focused on advances in simplification, integration, and process control. Simplification would be furthered by the introduction of standardized deterministic Ethernet, in other words, Time Sensitive Networking (TSN). Integration would be accelerated via tighter linking to OPC UA. Finally, I noted that process control networks are poised to go through a step-change with the release of the Advanced Physical Layer (APL).

So, where are we today with these advancements? Well, as promised, PROFIBUS & PROFINET International (PI) has released the specification for PROFINET over TSN in June 2019 and an OPC UA for PROFINET companion specification in August 2019. However, APL still remains on the horizon, and work continues.

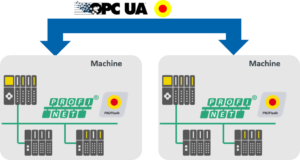

While these specifications are now in place, product development around them remains a work in progress. As that effort proceeds at the chip makers and automation vendors, other possibilities are opening up. For example, with OPC UA poised to become the favored way forward for machine-to-machine (i.e., controller-to-controller or C2C) communication, the next step is to look at any other use cases that could be addressed by such a solution. The missing piece yet to be addressed here is C2C failsafe communication.

Failsafe C2C Communication

Currently, solutions for C2C functional safety involve complicated systems that are difficult to implement, particularly across controllers from different vendors. Furthermore, certification of these safety systems can be a challenge if changes are required. At the I/O level, PROFIsafe has long been the preferred solution to enable performing safety in logic (instead of hard-wired relays). It only made sense to provide the same functionality at the M2M level also. Therefore, PROFIsafe has essentially been provided to the OPC Foundation expressly for this purpose. The first step has been to make it a companion specification, and in the next step to make it an OPC UA core specification.

Currently, solutions for C2C functional safety involve complicated systems that are difficult to implement, particularly across controllers from different vendors. Furthermore, certification of these safety systems can be a challenge if changes are required. At the I/O level, PROFIsafe has long been the preferred solution to enable performing safety in logic (instead of hard-wired relays). It only made sense to provide the same functionality at the M2M level also. Therefore, PROFIsafe has essentially been provided to the OPC Foundation expressly for this purpose. The first step has been to make it a companion specification, and in the next step to make it an OPC UA core specification.

The underlying technology here is known as the ‘black channel principle.’ It means that PROFIsafe messages are unconcerned with the underlying transport or physical layers—all that matters is that the safety message gets from its source to its destination. The same can apply for PROFIsafe over OPC UA and moving safety messages between two controllers.

Consider a scenario in which stationary machines are positioned alongside autonomous mobile robots (AMRs). How would you ensure functionally safe communication between the two? The idea is to have an AMR speak precisely with one machine at a time and dynamically establish a connection with it during runtime. The goal of using PROFIsafe at the controller level, combined with OPC UA, is to make scenarios such as these much easier to implement and certify.

Sensor to Cloud

Another use-case being addressed by PI in 2020 and beyond is the growing “sensor-to-cloud” trend. As computing power and memory have shrunk in size and cost, small low-cost sensors have acquired a certain level of intelligence. However, it still doesn’t make sense to put a $5 Ethernet interface on a $15 proximity sensor. Enter IO-Link—the last meter connection for smart sensors and actuators.

Another use-case being addressed by PI in 2020 and beyond is the growing “sensor-to-cloud” trend. As computing power and memory have shrunk in size and cost, small low-cost sensors have acquired a certain level of intelligence. However, it still doesn’t make sense to put a $5 Ethernet interface on a $15 proximity sensor. Enter IO-Link—the last meter connection for smart sensors and actuators.

With the IO-Link to OPC UA companion specification now released, an IO-Link master (typically an I/O block) can also double as an OPC UA server. On the one hand, it can exchange real-time data with its controller as a PROFINET device. On the other hand, it can provide data to OPC UA clients elsewhere as desired, e.g., the cloud. The potential applications here are many and varied. The reason this scenario works already today, and into the future, is because, in PROFINET networks, real-time automation control traffic coexists plainly with standard TCP/IP traffic. It can do this because it’s all Ethernet-based.

Beyond 2020

There are other topics to be addressed beyond 2020. The aforementioned APL, for example, still needs completion. 5G is a hot topic right now, and PI is looking at how PROFINET might fit into such an architecture. Data semantics is an ongoing effort with continued work invested to expand application profiles and adding value to data. The NAMUR Open Architecture, with its data diode, is another use-case receiving attention. All in all, the future is bright for industrial networking, with many exciting advances on the horizon, and I, for one, am looking forward to it.

–Michael Bowne