Future-Proof Combination

Asset management information, i.e. which devices are installed, in which version and in which condition, is highly sought-after in practice. Without such information, neither maintenance plans nor asset management or in-depth diagnostic functionalities can be used. The current challenge: How can such data be transferred from the field to IT, and how can information be obtained from it that is useful to the user? The “OPC UA for PROFINET” Companion Specification V 1.0 now provides answers to these questions.

Asset management information, i.e. which devices are installed, in which version and in which condition, is highly sought-after in practice. Without such information, neither maintenance plans nor asset management or in-depth diagnostic functionalities can be used. The current challenge: How can such data be transferred from the field to IT, and how can information be obtained from it that is useful to the user? The “OPC UA for PROFINET” Companion Specification V 1.0 now provides answers to these questions.

PI and the OPC Foundation have been working for some time on simplifying the interaction between PROFINET and OPC UA for the user. As middleware, OPC UA alone cannot provide data, for example, asset management data, for practical use. However, the approximately 30 million devices in the field that have a PROFINET interface can do it and have been able to do so since the zero hour of PROFINET, for example, through their corresponding Identification & Maintenance services. The OPC UA-PN-Companion Specification V 1.0 shows how this task sharing can be achieved.

Flexibility through PROFINET as “Real Switched Ethernet”

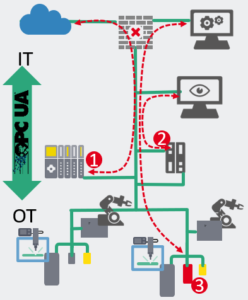

This allows the user to install additional Ethernet devices in a PROFINET network at any desired location. The existing automation solution does not have to be laboriously converted for this purpose. Thanks to the openness of PROFINET, even more complex sensors or devices with an OPC UA interface can be added flexibly. These send their values directly to corresponding cloud services or edge gateways. The interaction between OPC UA and PROFINET thus allows a flexible and thus future-proof solution.

OPC UA in PROFINET Networks

User-Friendly Network

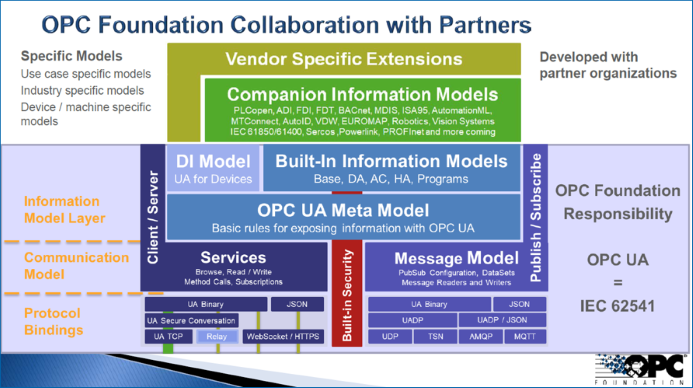

In a user-oriented and future-proof network, existing and new technologies function smoothly alongside one another as well as between cross-manufacturer solutions. A good example is the combination of OPC UA and PROFINET. With OPC UA as middleware, data and information models can become object-oriented. PROFINET, with its application profiles, virtually takes over the supply of the necessary information.

To ensure that this interaction works and is uniform for all PROFINET devices, the PNO established the ‘OPC – PNO Working Group-‘ as a joint WG with the OPC Foundation. The most important task was the standardized mapping of existing and proven data and information models from PROFINET to OPC UA. The goal was to create a ‘Joint OPC UA Companion Specification’. Since January 2020, version 1.0 of the specification has been officially released. This first version focuses on applications in the areas of asset management and diagnostics. The main objective was to map the different views of the various user groups.

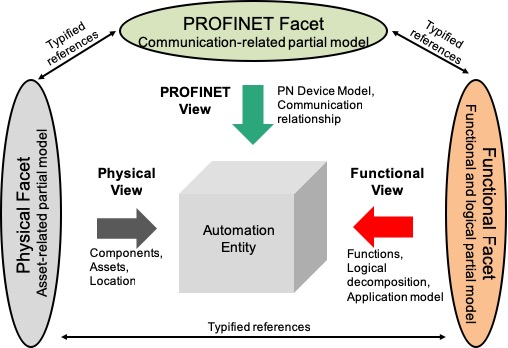

From a technological point of view, production data, or process sequences of a machine are essential, but from a maintenance point of view, the equipment used is important. Energy management also requires different information, while details about the network are interesting for a different user group. The PROFINET view deals with the representation of the devices and their communication relationships, a network view deals with interfaces and ports, and a functional view deals with the information model of a control loop or sensor function, for example. These different views of the same machine or plant must fit together, which is achieved by semantic references.

Which views, i.e. which submodels and data are important for everyday operation, were developed on the basis of a detailed use-case description within the framework of the Companion Specification.

In contrast to the classic Companion Specifications based on OPC UA DI, which only deal with the modeling of a device, the PROFINET Companion Specification refers to the modeling of a complete system automated with PROFINET with a large number of controllers and devices.

Accordingly, the PROFINET model consists of the controller and the device submodel. The controller submodel contains the PROFINET connections (application relations) with modules and submodules configured in the PROFINET controller. The device submodel consists of the PROFINET devices with their actually existing modules and submodules. These two submodels are connected to each other via OPC UA references.

In addition, the information model includes the mapping of the physical network topology of the PROFINET network. Thus, the exact cabling of the PROFINET devices with their Ethernet interfaces, ports, and cables is included in the OPC UA information model and can be used for network diagnostics. The OPC UA information model uses OPC UA Amendment 7 ‘Interfaces and Add-Ins’. An appendix to the specification describes the use of the information model as an example.

A ‘proof of concept’ trade fair model has already proven that this approach works in practice. Various use-cases, from controller-controller mapping to energy management, and NOA (Namur Open Architecture) connection of positioners, show that a wide range of applications is covered. Thanks to the openness of PROFINET, more complex sensors or devices with an OPC UA interface can be added, which send their values directly to corresponding cloud services or edge gateways without having to laboriously rebuild the automation solution.

Convincing Combination

PROFINET has been fulfilling diverse and complex tasks in the field for many years, for example, during machine startup, in engineering, or for redundancy requirements. More than 30 million field devices with a PROFINET interface provide relevant information. OPC UA complements this technology because it allows object modeling from a wide range of data sources. Thanks to this combination, the result is a real added value for users, as the following practical examples from asset management and diagnostics show. The first version of the PN-OPC UA Companion Specification focuses on these two applications.

Asset Management

Many users do not know which devices with which hardware or firmware status have been installed in a system over the years. Without such information, however, maintenance plans cannot be created, let alone managed properly. This is now being solved.

The first version of the PN-OPC UA Companion Specification solves the requirements of asset management and diagnostics with the following details:

Asset Identification

Listing of all PROFINET Nodes (Controller and Devices) with:

- Modules and submodules (Real and Expected)

- I&M and Asset Information (Tag Function, Tag Location, Versions, Vendor, …)

- Network Parameters

- Physical Topology of the PROFINET Network

Detection of Asset Changes

- New, Remote and Replaced Devices / Submodules – Docking Devices

- Firmware Updates in the Devices

- Changes in Physical Topology

Changing Asset Information

- Name of Station, Tag-Function

Diagnosis

More detailed information from the field is also required for intelligent diagnostic strategies. Here too, the PN-OPC UA Companion specification provides practical strategies.

- Display PROFINET Connections (ARs)

- Recognizing the differences between the configuration in the controller and the real assets (devices, modules, submodules)

- Reporting the PROFINET device diagnoses

- Network diagnostics (counter, wrong neighbors)

OPC-Server

OPC-Server

The corresponding OPC-Server in this illustration can be installed in different devices:

- PLC

- Gateway/Edge

- Direct Device-Integration

Depending on the application and environment, these solutions have various advantages.