For decades, PROFIBUS DP and PA provide process plants with excellent communication features and solutions. Now, Ethernet-based PROFINET opens the door to PROFINET for Process Automation. PROFINET is often used in process plants as the main network backbone, but PROFIBUS PA is still used where no Industrial Ethernet can go – into hazardous areas. This is not a limitation of PROFINET, but a limitation of Ethernet, since Ethernet was never designed as a hazardous area network.

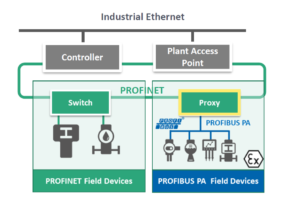

PROFINET provides a high-speed, high-bandwidth, backbone for PROFIBUS PA (and other fieldbus networks) similar to the way that PROFIBUS DP does. It differs slightly however by using a ‘proxy’ interface – a module that sits between PROFINET and the underlying bus. The data path via the proxy is fully transparent: instruments on the fieldbus appear directly connected to the PROFINET controller as remote IO. This makes the configuration, maintenance, and management of an automation system very simple from any part of the enterprise. Proxies exist for PROFIBUS PA and for many other bus technologies including Foundation Fieldbus and WirelessHART. The great advantage of the proxy approach is that existing field networks do not have to be replaced when upgrading a plant to PROFINET; investments in skills and inventory are protected as the migration to Industrial Ethernet architectures occurs.

PROFINET provides a high-speed, high-bandwidth, backbone for PROFIBUS PA (and other fieldbus networks) similar to the way that PROFIBUS DP does. It differs slightly however by using a ‘proxy’ interface – a module that sits between PROFINET and the underlying bus. The data path via the proxy is fully transparent: instruments on the fieldbus appear directly connected to the PROFINET controller as remote IO. This makes the configuration, maintenance, and management of an automation system very simple from any part of the enterprise. Proxies exist for PROFIBUS PA and for many other bus technologies including Foundation Fieldbus and WirelessHART. The great advantage of the proxy approach is that existing field networks do not have to be replaced when upgrading a plant to PROFINET; investments in skills and inventory are protected as the migration to Industrial Ethernet architectures occurs.

The PROFINET backbone can be used to connect other field devices typically found in process applications – for example, drives and discrete IO. Since most process plants are ‘hybrid’ (they include both process and discrete automation elements) only one network – PROFINET – is needed to cover the entire plant.

Learn more about the challenges in Process Automation, integration of existing Process Automation solutions in PROFINET, complementary and upcoming technologies.

Download Slide Set

Slide Set Table of Contents

Transition from PROFIBUS DP/PA to PROFINET

Transition from PROFIBUS DP/PA to PROFINET- Challenges in Process Automation

- PROFINET details

- Integration of existing PA solutions into PROFINET

- PROFINET benefits in operation (incl. PA Profile 4.0 for PROFINET)

- Supplementary/Upcoming technologies (FDI, NOA)

- Test and Certification / Summary / Further information