In this article, you can learn all about a crucial piece of infrastructure in PROFINET networks: the cabling. A PROFINET network is based on standard IEEE 802.3 Ethernet. Therefore, you can utilize standard Ethernet cables to build your PROFINET network.

You might have heard the term: PROFINET cable before. We will reference this term through the article, so it’s better to explain it from the start.

What Is a PROFINET Cable?

The factory floor, where PROFINET is most commonly used, is a harsh environment with challenging environmental conditions. In that environment, standard Ethernet cables, like those you find in your office or home, might break or damage easily. For that reason, industrial Ethernet cables are a common choice.

The factory floor, where PROFINET is most commonly used, is a harsh environment with challenging environmental conditions. In that environment, standard Ethernet cables, like those you find in your office or home, might break or damage easily. For that reason, industrial Ethernet cables are a common choice.

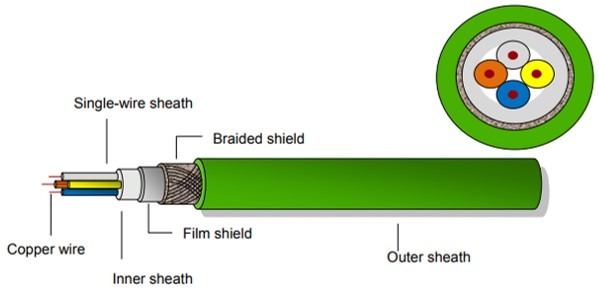

On the wire, Industrial Ethernet is just Ethernet. Yet, Industrial Ethernet is characterized by rugged hardware, and its wiring is protected with shielding and jacketing.

Many vendors offer Industrial Ethernet solutions, and some produce cables specifically for PROFINET, which we call PROFINET cables. They often come with a green jacketing and comply with ruggedized specifications that have been standardized by PROFIBUS and PROFINET International (PI).

Cables in PROFINET Networks

Now, we can cover an in-depth description of cabling in PROFINET networks. PROFINET cables come in two flavors: copper and fiber optic.

Copper Cables

The most common PROFINET copper cable is a 4-wire shielded, green-colored cable, which supports 100 Mbps Fast Ethernet at a distance of 100 meters. Full-duplex transmission means data can be transmitted in both directions through one cable simultaneously. Also, 8-core copper cables are available for 1 Gbps transmission rates.

To go further distances than the 100-meter limit, you have to install a node, like a switch, every 100 m. It’s similar to cable segments as a limiting factor in traditional fieldbuses. For instance, in PROFIBUS networks, you would implement PROFIBUS repeaters between components to go longer distances.

The four-wire cable can either be realized as two twisted pairs or as a one star-quad. On the one hand, twisted pairs can help reduce crosstalk between the wires, but on the other hand, star-quad cables are easier to install.

The structure of the wires in copper cables can vary. They can have a solid core or stranded core, and variations in the jacket material and construction. Stranded core cables, for example, are more flexible. They are suitable for indoor applications where twisting and bending can occur. Different jacketing materials can provide resistance to flames, chemicals, or extreme temperatures or, in specific applications, come in different colors.

There are four PROFINET copper cable types: A, B, R, and C.

- Type A cables are for fixed installations. They should not undergo motion after commissioning.

- Type B cables are for installations where flexing may be present. These cables can withstand occasional motion or vibrations.

- Type R cables are for robot applications and are tailored for that specific usage.

- Finally, Type C cables are for other specialized applications. They can withstand movement and dynamic environments, for example, rotary machines.

There are also other cable classes for specific applications, such as buried cables for underground communication, flame retardant non-corrosive cables for fire protection, trailing cables for moving parts, and many others.

CAT 5, 5E, CAT 6, 6A, and CAT 7 Cables in PROFINET Networks

A common question about copper cables in PROFINET applications is if you can implement Cat 5, 5e, Cat 6, 6a, or Cat 7 cables in PROFINET networks?

The short answer is “Yes,” you can implement those cables. However, the categories only specify the performance of the cable like achievable frequency, speed, crosstalk, and signal to noise ratio. You must also check the specifications of each cable.

Some older Cat 5 cables, for example, are unsuitable as they are only capable of 10 Mbps speeds, which is below the required 100 Mbps for PROFINET. That said, Cat 5e is the most common, as it can fulfill the 100 Mbps transmission speeds. Cat 6, 6a, and Cat 7 cables can provide transmission speeds of up to 10 Gbps. Such high rates might seem unnecessary based on current hardware transmission speed capabilities, but some users choose to future-proof their network with them.

PROFINET networks can employ all of these Category cables, but it’s not the whole picture. The cabling you choose should also be a “PROFINET cable” and meet the PI specification for use in industrial environments.

Fiber Optic Cables

Besides copper cables, PROFINET can also employ fiber optic cables.

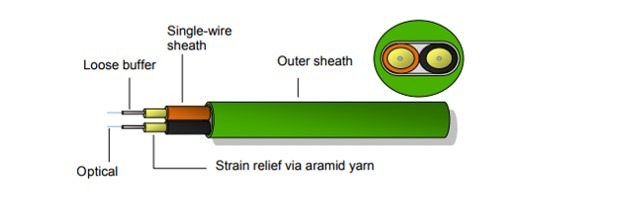

A PROFINET fiber optic cable’s scheme consists of two parallel wires. The wires are ready for the direct assembly of connectors. Printed directional arrows help facilitate the wires’ assignment to the transmit and receive connections. PROFINET fiber optic cables have speeds of up to 100 Mbit/s and full-duplex communication over two wires.

Fiber cables offer benefits in particular instances. They can cover distances of kilometers, and they provide total electrical isolation between plant areas. Also, fiber cables are immune to electromagnetic interference.

There are two PROFINET fiber optic cable types: Type B and Type C. Type B cables are meant for stationary or flexible use. Type C cables are designed for special applications like, for example, permanent movement, vibration, or torsion.

Four different fiber classes can be employed when using optical fibers for PROFINET. Those four classes are: POF, multi-mode glass fiber, single-mode glass fiber, and glass fiber with a plastic jacket.

Important Cabling Considerations

Distance: Individual copper segments are limited to 100 m before the signal must be refreshed, for example, with a switch. Fiber optic cables cover longer distances by default; some run for over 100 km long.

Cost: Cost is a crucial factor when building a network. Since cable costs vary depending on the general type and functionality, you must create a budget based on each project. Also, remember to consider additional expenses besides the cable cost per meter. During installation, each cable will require testing equipment, connectors, and adapters. Also, different cables may require installation training.

Environment: Both copper and fiber have multiple cable types available for different conditions. Always choose the appropriate type depending on the environment: fixed, flexible, or dynamic installations.

Electromagnetic Interference: Because copper cables operate through electrical signals, they can be susceptible to the effects of electromagnetic interference. That is why you must be careful when running power cables and data cables close to each other. Also, VFDs and other industrial equipment can be significant sources of EMI. Fiber optic cables cannot be affected by external magnetic fields as they are immune to EMI.

Availability: Most devices in an industrial network have built-in connections that support copper media. You can employ a media converter to transition to fiber, but it is an extra step to keep in mind.

Summary

You can employ standard copper or fiber Ethernet cables in PROFINET networks. Utilizing PROFINET cables is a huge benefit, as they are ubiquitous, affordable, and versatile. Many cable manufacturers offer competitive products.

You are always able to find the right cable for each PROFINET connection. Copper and fiber cables have type classifications to indicate what degree of movement they are built to withstand. And manufacturers also offer cables for special applications. Finally, when commissioning copper or fiber cables, always remember to follow proper installation guidelines available for free from PI.

Download the PROFINET Cabling White Paper for more information: