Everything is Moving – OPC UA Companion Specification “Global Positioning”

Everything is moving – this expression describes best the dynamics in production and logistics today. Products, robots, autonomous vehicles, and humans in between. To ensure a smooth production flow in such a mobile environment, machines and software systems need a common understanding of the positions of things in space.

Some associations have already dedicated themselves to the aspects of “location and positioning” in the past. Some OPC UA Companion Specifications already contain data descriptions in this regard. Coming from the aspect of identification, the association AIM-D e.V. published an OPC UA Companion Specification AutoID. The location standard omlox from PROFIBUS & PROFINET International (PI) allows seamless and technology-independent provision of location data in production and logistics.

The three associations have now joined forces to form a joint working group to develop a new OPC UA Companion Specification “Global Positioning”. The goal of the Companion Specification is to define geometric positions in space on a local and global level to ensure a seamless transition between production, intralogistics and logistics. It completes existing Companion Specifications with the aspect of positioning and allows location data from omlox systems to be easily further processed within the OPC world and refined with additional data.

“Interoperability is not only necessary between manufacturers, but also between standards,” says Dr. Matthias Jöst – Committee Leader for omlox – within PI. “In particular in the exchange between different communities, many synergies and new potentials arise.”

Holistic and Automated Material Flow with omlox

Due to increasing and volatile demand in eCommerce, shaken supply-chains and labor shortages, there is a lot of emphasis on automation in intralogistics these days. Logistics companies are deploying automated guided vehicles, robots and invest in modernization of their IT landscape. Systems are becoming increasingly complex which poses the need for interoperable and open standards. In this context, the open locating standard omlox hosted by PI (PROFIBUS & PROFINET International) can be a real game-changer, as it can provide full transparency on every movement in logistic sites. It specifies a locating-middleware to aggregate location data in a technology-independent manner (omlox hub) and an interoperable ultra-wideband system (omlox core zone) to provide real-time tracking in challenging environments.

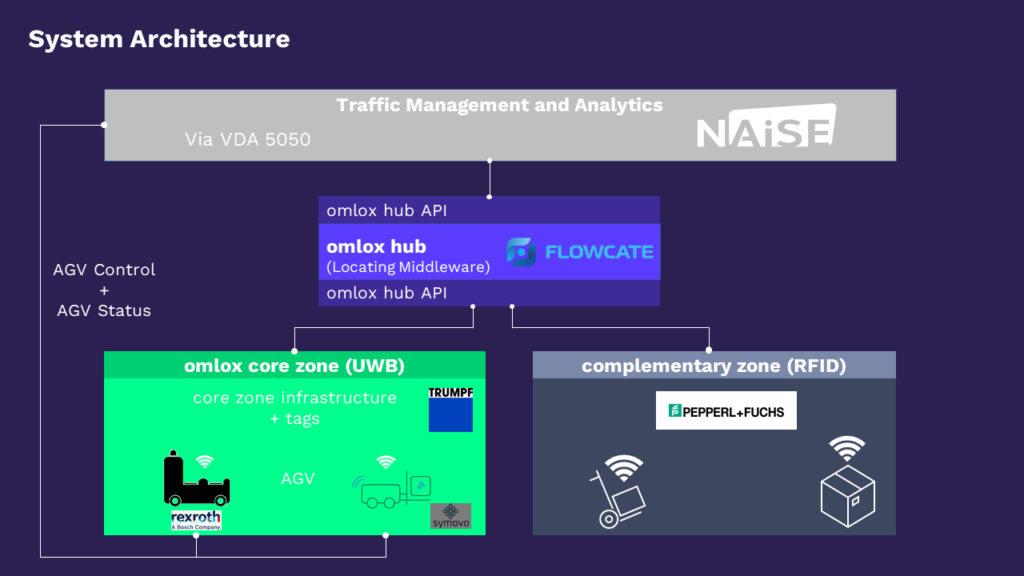

A group of omlox partners has joined forces, to demonstrate by means of a showcase a holistic automated material flow, following the omlox architecture and the specified APIs. In this setup, NAiSE is providing its fleet management solution. This traffic management software uses the VDA 5050 standard to orchestrate AGVs and is adopting the omlox APIs to receive information about locations of other objects like persons, palettes, or small load carriers. Those objects are tracked within an omlox core zone, by TRUMPF Tracking Technologies and by using RFID from Pepperl & Fuchs as omlox complementary zone. The location data is aggregated within an omlox hub, provided by Flowcate. Furthermore, the omlox hub is providing spatial events like fencing and collisions, to foster a frictionless material flow and safety on site.

As all partners follow the standardized omlox API and architecture, the overall system becomes “plug and play” and further locating technologies and use-cases can easily be added. It provides the framework for a future proof setup on a logistic site, while incorporates existing technologies. Due to the fact, that an omlox application provides geo-references location data, the complete system can be embedded into general supply chain management solutions, to enable a seamless tracking of material across sites.

Application Scenarios/ Use of Location data:

- Getting different position data in one system (Manual Guided Vehicles & Persons via UWB, AGVs/AMRs via NAiSE APP, Load carriers via RFID)

- Triggering Geofence Events with position data

- Geofence Event for Traffic Light

- Narrow Zone Event

- Order Triggering via RFID Position data

- Traffic Management to control AGVs/AMRs regarding position data

- Analytics with position data in NAiSE APP

IoT: Energy-optimized Intralogistics for Sustainability

Intralogistics is all about the movement of materials in manufacturing or logistics facilities. From forklifts and automated guided vehicles to locating tags – expending energy 24/7. Monitoring energy consumption inbound and outbound, and optimizing it in real time, is a challenge.

To monitor energy consumption, you need a flexible system, a technology stack easy and modular enough to be deployed, gathering telemetry and location data, unifying it, and aggregating in a platform to perform further analysis and provide insights. For example, how can you know the forklift’s fuel consumption at any given time, and which is the best route to optimize it? What if you had 1,000 forklifts in each of 25 distribution centers or production plants?

Thanks to a collaboration between Software AG and location-based service solutions provider Flowcate, industrial sensor and edge gateway manufacturer Sick AG, and machine maker and Real-Time Locating System (RTLS) provider TRUMPF, there is a solution.

The omlox locating standard provides unified access to locating data with its standardized APIs and provides interoperability within the ultra-wideband RTLS components from different vendors. This enables the creation of sustainable processes in manufacturing and logistics, optimizing materials flow. It is the world’s first open locating standard. Yet for this collaboration to achieve this goal, a solution must encompass a wide range, supporting real-time tracking both indoors and outdoors.

For indoor tracking, TRUMPF implemented omlox’s standardized air interface compliant interoperable ultra-wideband (UWB) system. In real time, the platform can see the movement of all mobile assets indoors.

Dual-location technology of not only forklifts, but other devices on edge or customer data centers, allows for that same vital data to be tracked beyond the shop floor. This is where Sick AG’s gateway came in to track forklifts from indoors to outdoors, pulling location and energy consumption data.

To make sense of all that data from multiple indoor and outdoor locations, centralization was key. Flowcate served as the central datahub of what Sick AG and TRUMPF provided. That hub offers a holistic overview via locating-API middleware operating in the cloud, on edge or even in hybrid setups. With this software, anyone could see the data that fences, zones and more would aggregate with ease.

The tech does not stop there. We at Software AG offered a customized Cumulocity IoT platform to take the aggregated data and conduct further analysis. The assessment determines areas of inefficiencies that can be rectified in aspects such as fuel consumption, duration of operation and other factors.

This complex collaboration is ambitious in its modular approach, but flexible and adaptive to any potential location. Hence it can apply to any distribution center, vendor or company seeking to maximize operations and productivity.

The key is in ensuring all the data aggregates and filters – like branches – to optimize material flow for several purposes, one in particular: reducing carbon footprint.

Sustainability: A key factor of success in the manufacturing and logistics industry

Having a solution that aims to reduce everything from emissions to electricity usage and more makes for a better tomorrow – all while optimizing operations and making it that much easier for production and distribution to produce and deliver to customers to receive.

Flowcate, SICK AG, Software AG and TRUMPF Tracking Technology present a holistic energy monitoring solution in the framework of the open locating standard – omlox. It is a perfect example of technology companies working together for the greater good.