Why are so many isolating switching amplifiers and pneumatic valve terminals still installed in large control cabinets to send intrinsically safe signals and pneumatic drives from Ex zoned areas?

There are numerous concepts for planning of potentially explosive systems, such as the optimization of the zoning, the reduction in size of zoned areas or the wish to run everything out of hazardous areas into a central cabinet via cable routes. The crux of the issue is that the calculation of the cabling is often not within the scope of the plant or- machine builder. Logically speaking, the effort and costs arise elsewhere, but they do not vanish into thin air. An innovative solution while considering the potential trade-offs must be carefully considered.

It is clear that many plants, especially in the chemical industry, have long been equipped with Ex remote I/O systems. Large and modular remote I/O cabinets are widely established in this industry. In this article I would like to draw the attention of plant and machine builders to a new concept.

What is new about it and what are the benefits?

What is new about it and what are the benefits?

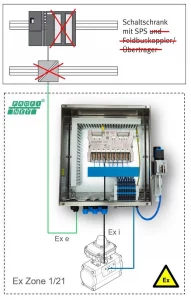

The new concept for zoned areas is: Place small remote I/O valve terminals distributed within a system instead of building central or large decentralized solutions. The aim is to collect the intrinsically safe signals on-site and to supply the pneumatic drives decentrally via short pneumatic lines. From there, communication takes place directly via PROFINET to the controller.

Newly developed technologies from non-hazardous areas are usually upgraded and certified for zoned areas with a time delay. In the case of products for Zone 2/22, this may happen very quickly. However, for devices for Zone 1/21, which also supply sensors from Zone 0/20, new and innovative products can usually only be implemented with considerable effort by the manufacturer.

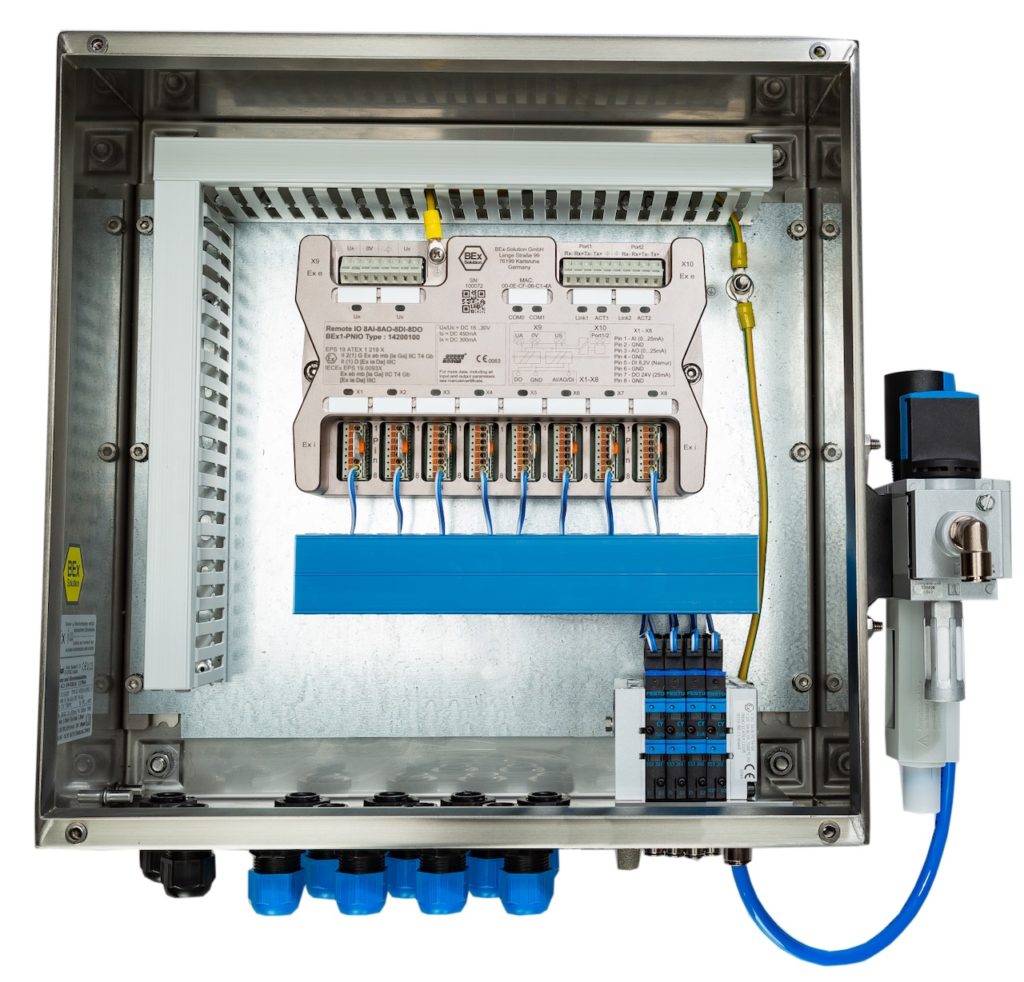

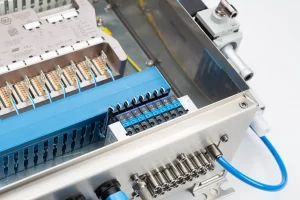

Through the successful partnership between BEx Solution, FESTO and Exepd, the 3 in 1 solution was created, which as a result provides an innovative, tried-and-tested and certified compact remote I/O valve terminal for potentially explosive areas in Zone 1/21.

What added value results from this solution? Space, time and money. The small boxes combine bus nodes, isolating switching amplifiers, intrinsically safe I/O channels and the valve terminal, guaranteeing short distances to the sensors and the pneumatic actuators. Connect compressed air, power supply and PROFINET, quickly and easily.

Now many will say ‘yes, but what about the software effort?’ Those who already have experience know that it does work but costs a lot of time and money. We are back on the big topic of resources. When developing the new concept, particular care was taken to ensure that the remote I/O module itself does not have to be configured. Communication and I/O settings take place via 64 I/O bytes.

Areas of application: Painting plants, pharmaceutical and chemical industry, bulk goods plants, mixing/grinding plants, industrial heating/cooling systems, sewage plants, and much more.

Functions: The connection is possible via PROFINET . Up to 16 pcs 3/2-way valves or up to 8 pcs 5/2-way valves can be configured, or combinations thereof. 16 Namur inputs are available for the position indicators. The module is also equipped with analogue 4 to 20mA Ex i signals.

One final point: Many customers like the compact concept very much, but they have decided on existing solutions based on long-term specifications by their end customers or company-specific specifications. That is certainly the reality, especially in explosion-prone systems, where technology should last for several decades. With existing and well-performing systems, you have to think twice about a change. But when it comes to modernizing old systems or planning new systems, we recommend that you take a closer look at this solution which will enable more flexibility in the future.

More information at: https://www.bex-solution.com/en-gb/bex1-remote-io-valve-terminal

Contribution by Karl Vogel CMO – BEx-Solution GmbH