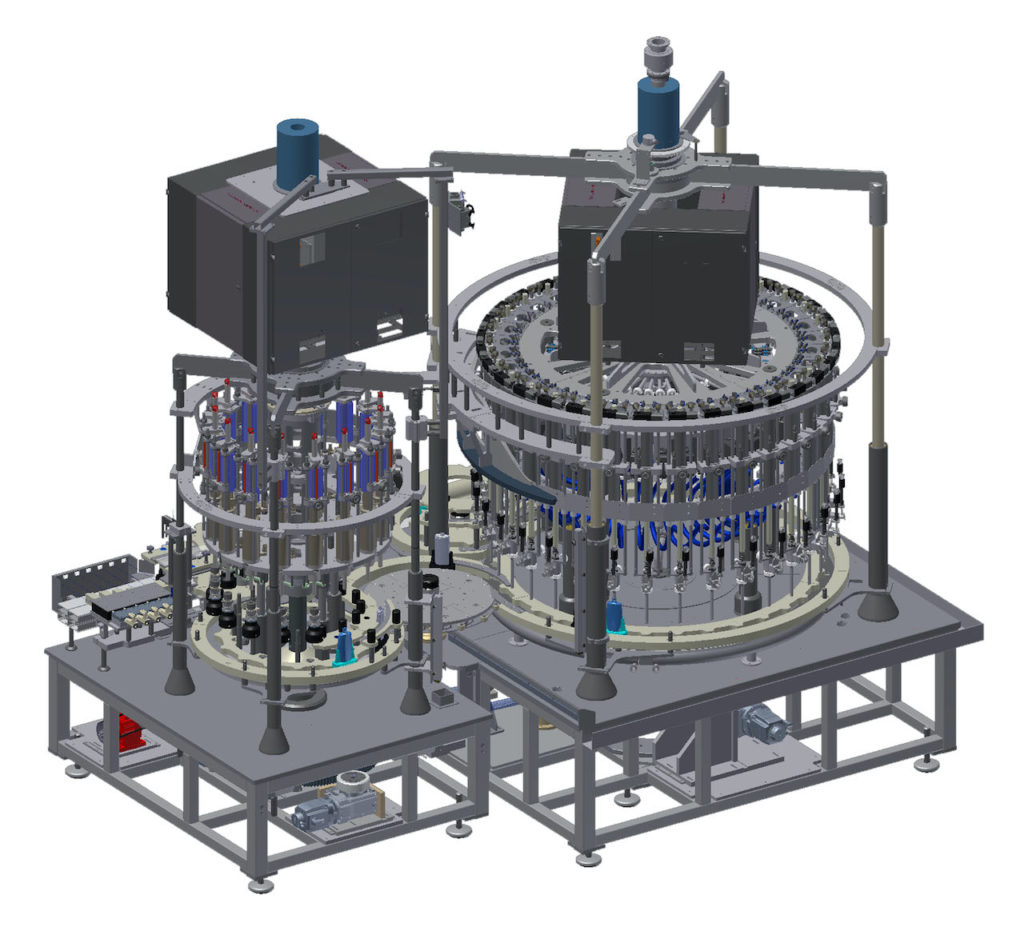

Many users wish they could combine the advantages of flow-rate metering and piston metering in one rotary filling machine. Tölke, a specialist in packaging machinery, has pulled off this feat by using LinMot linear motors and servo drives. The operator of the system benefits from short changeover times, less scrap, shorter downtime, and a more flexible machine.

With the complete solutions of servo motors and servo drives from LinMot, the filling process can be adapted much more easily to individual product requirements and a product change can be carried out more quickly, as more and more users are demanding. Thanks to LinMot, those production changes that require a change in the stroke movement of the filling needles can be carried out at the simple push of a button. This eliminates the time-consuming and costly conversion of the mechanical lifting curves.

However, the use of LinMot linear motors and drives offers even more important advantages that optimally support modern Industry 4.0 concepts: Information provided by the servo drive, such as the current motor temperature or the course of acceleration, can be used to monitor the filling process in order to detect mechanical problems (condition monitoring) or collisions at an early stage. In addition, the variety of fieldbus interfaces and protocols makes it easy to integrate the LinMot servo drives into any control system, be it a PLC, an industrial PC or a proprietary control system. Via PROFINET – as is already the case with several Tölke developments – complete drive configurations can be loaded, thus covering a wide range from simple point-to-point movements to complex multi-axis applications.

Thanks to this smooth interaction of the LinMot drives and PROFINET, Tölke can realise a wide variety of motion profiles and thus, for example, fill differently shaped bottles without having to adjust the entire structure of the mechanical system. Thanks to the precise position measuring system of the linear motors, the filling needle can also be moved with an accuracy in the tenth of a millimetre range above the filling level. The acceleration values when lowering and raising the filling needle can also be individually adjusted as required in order to reduce the loads on the mechanics and optimise the handling of the filling medium – completely in line with the precision of Industry 4.0.

Thanks to this smooth interaction of the LinMot drives and PROFINET, Tölke can realise a wide variety of motion profiles and thus, for example, fill differently shaped bottles without having to adjust the entire structure of the mechanical system. Thanks to the precise position measuring system of the linear motors, the filling needle can also be moved with an accuracy in the tenth of a millimetre range above the filling level. The acceleration values when lowering and raising the filling needle can also be individually adjusted as required in order to reduce the loads on the mechanics and optimise the handling of the filling medium – completely in line with the precision of Industry 4.0.

Author: Franz Rossmann, Technology Journalist

Editor: Mihaly Vidovenyecz, Technical / Social Media Writer