In part one of “Why PROFINET for Digital Transformation” we looked at the factors influencing the transformation of industrial networks. The end result of which is the transition from serial fieldbus technology to Industrial Ethernet-based networks where any device can be connected to any other device. But it’s not just about connectivity, it’s equally important that we move from a “one bus, one protocol” mentality to a “one network, multiple protocols” philosophy. Having access to multiple protocols opens our minds and our networks to using the right protocols for the right tasks. In part two we look at why PROFINET enables digital transformation in the context of this “one network, multiple protocols” philosophy.

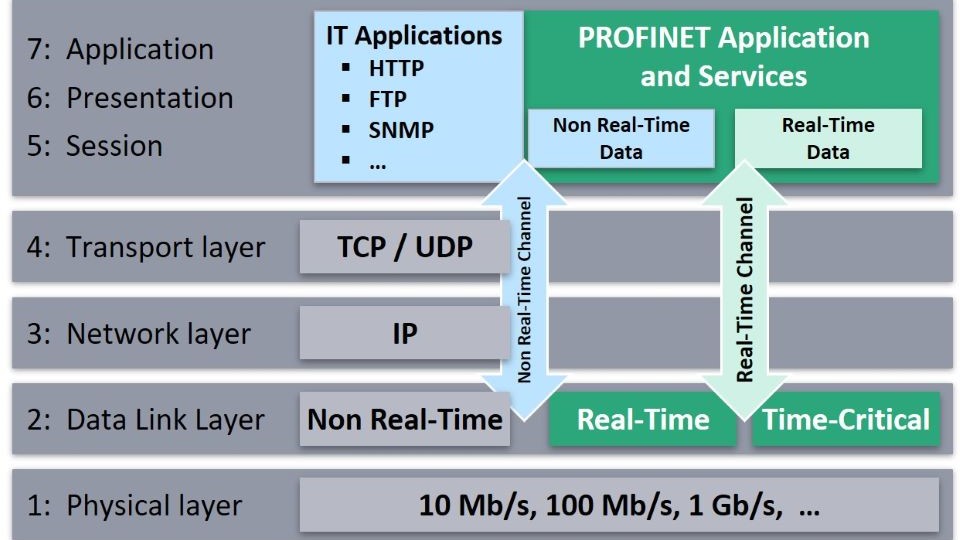

PROFINET works by separating Ethernet traffic into a real-time channel and a non real-time channel. To do this, PROFINET uses a field in the Ethernet Frame called an EtherType and we use this Ethertype to distinguish between real-time frames and all other frames. Messages with the PROFINET Ethertype go into the real-time channel and messages with any other Ethertype go into the non real-time channel. And this is how we can use the same standard unmodified Ethernet for PROFINET as we can for all other IT protocols. As shown in figure 1, the real-time channel provides real-time data exchange to keep the factory running, and the non real-time channel provides non real-time information exchange to get data from the factory floor to a higher level. Machines that speak PROFINET do so through the real-time channel and these messages coexists with all other messages so information can pass from devices to machines to factories to the cloud and back.

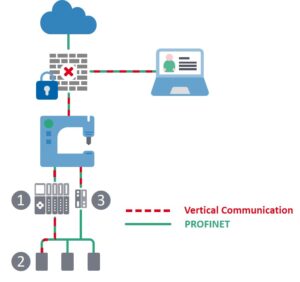

So why is this important? Two words: Vertical Integration. We need PROFINET to keep the factory operating, but we also need to get data in this operations part of the network to a higher level. So we need vertical integration. And this is where OPC UA comes in. OPC UA is really good for Vertical Integration – like device to cloud, as shown in Figure 2.

Because the real power of OPC UA is its information models. They are self-describing, machine-readable, and semantically rich. So now a machine can connect to an information model and it doesn’t need to know a priori what it’s looking for or how the data is arranged, the information model itself tells it. And since we have PROFINET for real-time data exchange on the factory floor and OPC UA for non real-time information exchange from the factory floor to the cloud, we have written companion specifications to map PROFINET data to OPC UA information models. We have done this for PROFINET Asset Management, Diagnostics, and our Application Profiles – we have even done this for IO-Link. And this mapping is the same whether it is done in a PLC, in a Device, or in an Edge/gateway.

The reason why you might want to do this mapping in a PLC is if there is some data dependency in the PLC application, or there is some other advantage in the PLC at the IO level. It may be that it doesn’t make sense to add an Edge/gateway to the network. But in any of these cases, you need to make sure you don’t disturb the PLC performance by retrieving data from the OPC UA Server integrated in the PLC.

If you don’t want to touch the PLC or maybe it is max’ed out in terms of its capabilities, another option is to send data directly from a device to a higher level. Sending data directly from a device can also prevent a PLC or Edge/gateway from being overloaded by a large number of devices on the network. There is so much interest in getting data out of devices that we are starting to see products in the market with both a PROFINET interface in them AND an OPC UA interface in them. And this use case really highlights, more than anything else, the power of PROFINET technology. Deterministic, real-time communication – PROFINET handles all of that. Non real-time information exchange – OPC UA handles all of that.

The third use case for Vertical Integration is to use an Edge Gateway or Edge Computer. If you find yourself in a brownfield environment and you don’t want to touch the PLC, or there is a large amount of raw data on the network, an Edge Computer is a good choice because it doesn’t make sense to send all of this raw data directly to the cloud. It makes more sense to process this data at the Edge – with an Edge computer – and then send OPC UA information to the cloud. If you have just a little bit of data to get to the cloud, an Edge Gateway may be a better choice. This type of Gateway reads PROFINET data from the network, translates it to OPC UA, and then sends the OPC UA information out to the cloud.

The bottom line of both part one and part 2 of this article is that our journey towards digital transformation requires an OT protocol that can meet the requirements for determinism, redundancy, safety, and security while also supporting IT protocols for vertical integration. So to answer to the question, “Why PROFINET for Digital Transformation?” It is because you can use PROFINET to run the factory, and it coexists with any other protocol on the wire – like OPC UA for vertical integration.