The annual independent notary recording of installed products with interfaces using technology from PROFIBUS & PROFINET International (PI) yielded very positive numbers for 2022. This is especially true for PROFINET and IO-Link, but PROFIsafe achieved a considerable increase over the previous year as well.

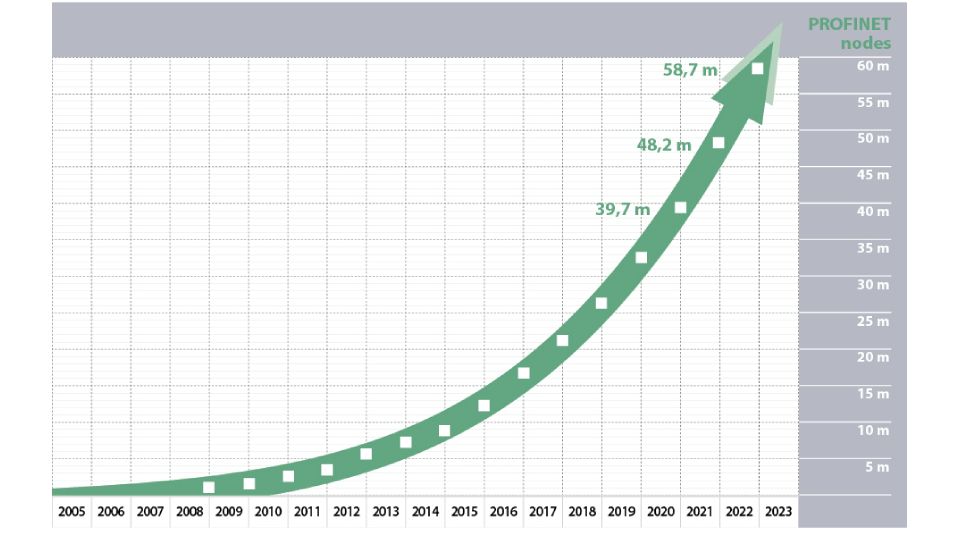

In the case of PROFINET, the count yielded a never-before-seen number of 10.5 million nodes added to the total. In 2022, 2 million more new PROFINET devices were put on the market than in 2021. This corresponds to an increase of 23.5% over the previous year. Altogether, a grand total of 58.7 million PROFINET products have been installed in systems by the end of 2022.

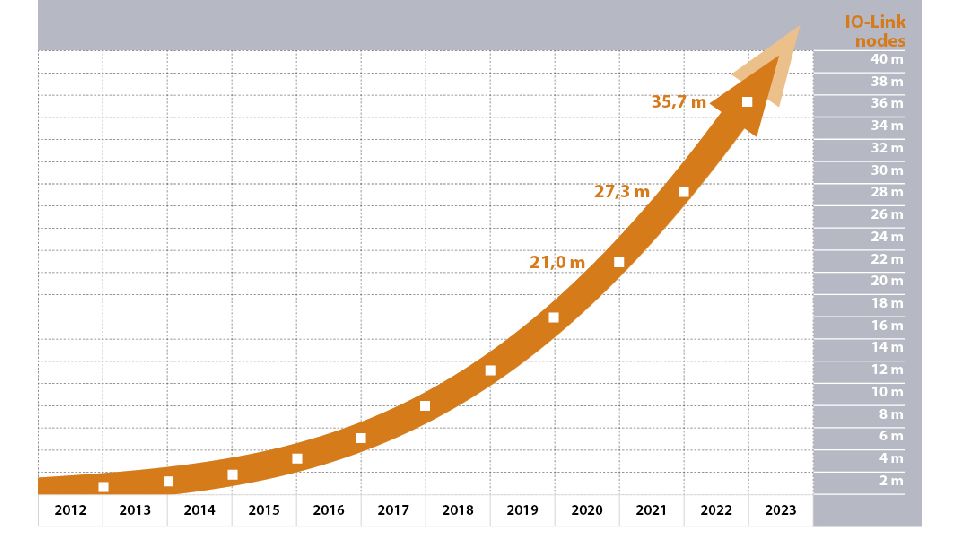

In the case of IO-Link, 8.4 million IO-Link nodes were integrated into systems last year. This means that 2.1 million more nodes were installed than in the previous year (2021), which corresponds to an increase of 33% over that year’s number. In all, a total of 35.7 million IO-Link nodes was reached by the end of 2022.

“These numbers and the trends of previous years impressively prove that our technology hasn’t just arrived on the market, but will remain a market leader for the long term,” said Karsten Schneider, PI Chairman, with delight. “We made the right decisions, our experts in the working groups did an outstanding job and member companies implemented a large number of marketable products. For this, I would like to thank the entire community,” said Schneider.

Another highly successful technology is PROFIsafe. The highest value ever in one year of 2.8 million nodes was reached in 2022. This brings the total number to 21.7 million. With a count of 1.5 million new devices for the year, PROFIBUS reached the same number as the previous year. The situation was similar with PROFIBUS numbers in process automation. With a count of 0.8 million in 2022, the value remained stable compared to the previous year. Accordingly, a grand total of 67.4 million PROFIBUS devices have been put on the market, with 15.4 million of them having been installed in process plants (PROFIBUS PA).

To maintain this trend over the next few years, the entire PI community is working on further establishing PI as an enabler for digitalization in industrial automation applications. The marketing working groups are continually coordinating the requirements for the various different areas of application with end users, and the technology working groups are working intensively to implement them in corresponding innovations. These innovations not only involve the expansion of existing technology, such as the integration of Ethernet-APL into PROFINET, but the inclusion of new technologies which advance digitalization as well. Examples here include the omlox location-tracking standard and the Module Type Package (MTP) standard.