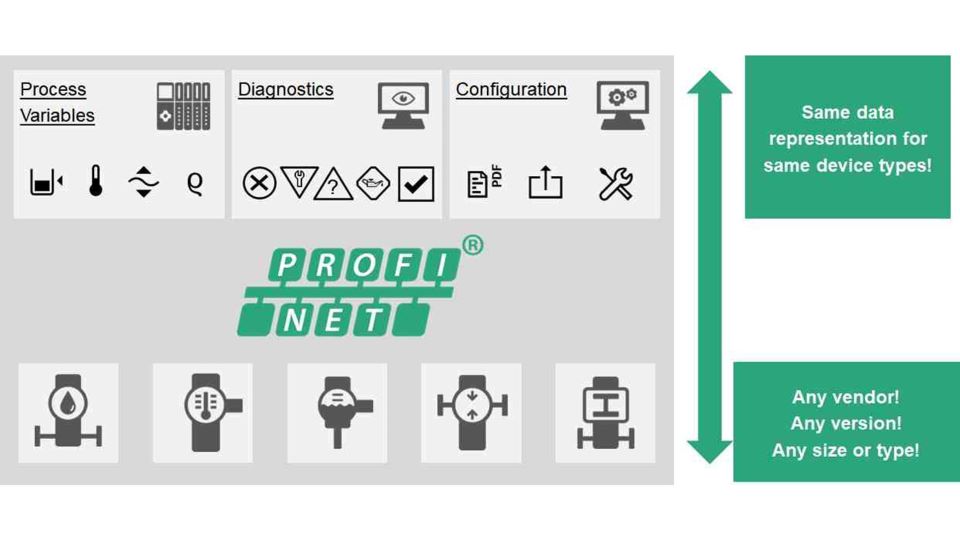

With PROFINET over APL, PI provides a new, Ethernet-based communication protocol for the field level of process automation, which meets all requirements for robustness and simplicity on the basis of the new Advanced Physical Layer (Ethernet-APL). PROFINET over APL ensures fast, seamless access to data in field devices in process plants and combines the advantages of Ethernet-APL with proven PROFINET technology.

Now, the challenge is to integrate further elements into the new technology. PA device profiles, in which important parameters and functions are specified uniformly across manufacturers, for example, have long proven themselves in process automation. These device profiles lead to identical operating sequences and similar behavior in the PA devices during engineering and operation, regardless of type and manufacturer. Standardized manufacturer-independent error messages, in accordance with NAMUR recommendation NE107 and taken into consideration in PA Profile 4, simplify the handling of field devices.

PA Profile 4 has now been implemented for the first time in field devices with PROFINET over APL, making it possible to implement workflows for automatic device replacement – even between different manufacturers. If a replacement device is connected in the place of the previous device, the new device is automatically detected and parameterized. This restores the basic functionality of the field device.

With the completion of the work surrounding PA device Profile 4, another milestone has been reached on the way to flexible and, at the same time, more secure process automation. In combination with PROFINET over APL and its high bandwidth, seamless integration from the field level into the entire PROFINET network is possible. For users, this means that not only can the efficiency of operating a plant be significantly increased, but also the effort required for training maintenance personnel is reduced.