The omlox technology group is continuing to expand its range in new industries all the time. As a result, omlox-based systems are now being used in the healthcare sector, retail trade, energy supply and mining, in addition to many applications in mechanical engineering and logistics. “The working group now oversees more than 300 use cases,” said Dr. Matthias Jöst, Head of the Committee omlox at PI (PROFIBUS & PROFINET International).

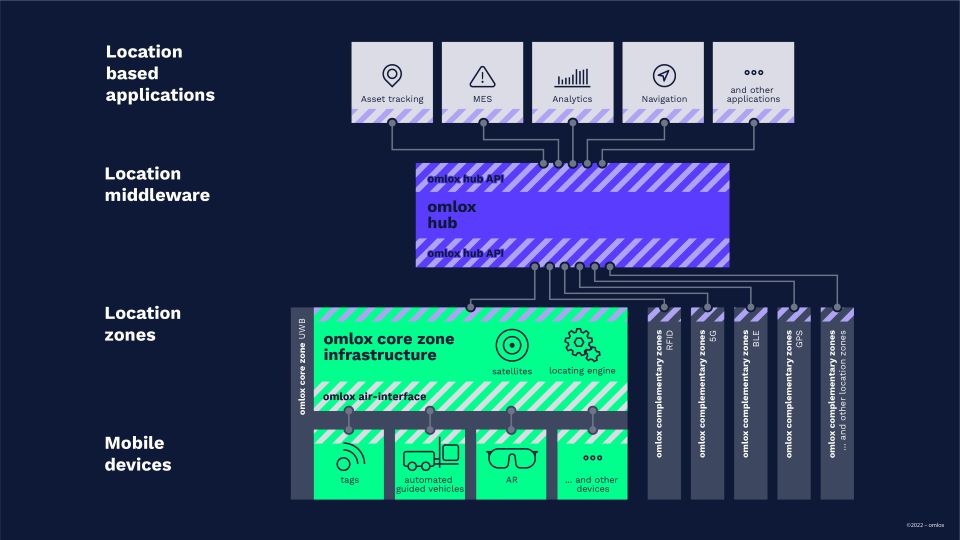

Knowing the “where”—that is, the precise locating of items and equipment—concerns just about every area of life, from the daily search for a key to the localization of tools on a shop floor and from the tracking of medical equipment at hospitals to the locating of shipments throughout the delivery process. “The advantages of the omlox real-time localization system are able to truly shine in applications like this,” explained Dr. Jöst. “Open, manufacturer-independent omlox technology makes it possible to exchange position data regardless of the manufacturer.” The major advantage here is that omlox enables the integration of industrial software and hardware solutions in a shared ecosystem. This makes it possible for companies to use a single infrastructure in different applications from different suppliers. As omlox makes all locating technology available via standardized APIs, the wide variety of implementation variants do not face limitations or restrictions—depending on the industry and use case.

In addition to suppliers of UWB locating technology, the omlox community now also includes manufacturers of LiDaR, Bluetooth & ultrasonic sensors and GNSS. This enables the seamless locating of objects from the global scale all the way down to the millimeter scale on a desk, and the technology is now being rolled out across the world. In early December, the omlox community met up in China, where an integrated demo was presented by Chinese technology suppliers.

International standardization is continuing to advance as well. Thanks to cooperation with several associations, such as the OPC Foundation and the Industrial Digital Twin Association (IDTA), the vision of transparent data exchange along the value-creation chain is one crucial step closer to reality. The OPC is currently working on a companion specification for locating. ECLASS 14 now includes a locating concept for products, and sub-model asset locating for the mapping of spatial product traceability will be completed by the IDTA by year’s end. This makes it possible to locate a product throughout its entire life cycle.

Test Lab Commences Operation

The world’s first omlox test lab began its work in November 2023. PROFIBUS & PROFINET International (PI) has accepted the Fraunhofer Institute in Lemgo, Germany as a PI test lab for omlox. This enables manufacturers of tracking technologies to have their products tested according to the omlox standard at an independent test lab. The PI Certification Office creates certificates on the basis of positive test reports. The use of certified products in systems achieves a high degree of interoperability.

The function and interfaces of the manufacturer-independent omlox technology are described by standards. In order for components (hardware and software) from different manufacturers to work with one another in a system, the components must be implemented precisely following the standards. This is referred to as conformity. Conformity must be checked to ensure a high level of system quality and usability for users. At the world’s first test lab for this purpose, conformity is now being tested and confirmed so components can receive an omlox certification.

For the first time, omlox enables the technology- and manufacturer-independent provision of location tracking information in production environments. Various different localization technologies, such as ultra-wideband wireless (or UWB, which is widely used in localization systems thanks to its robustness), 5G, RFID, QR codes and GPS, can be used together and with standardized interfaces in an omlox system. The standard also ensures that so-called omlox satellites (components of the location tracking infrastructure in a building) can be integrated with omlox tags (devices tracked via signals) regardless of the manufacturer.

Users are therefore able to implement future-proof, manufacturer-independent tracking systems based on omlox-certified products. Thus, omlox achieves a new level of transparency and is therefore regarded by experts as a pioneering location tracking standard with key functions for the advancing digitization taking place in industry and logistics. The availability of the first test lab marks a milestone for the omlox localization standard and its global distribution.