Recent events in the UK and the Netherlands featured PROFINET, PROFIBUS, and IO-Link. The UK had two events, one focusing on factory automation and one on process automation. In the Netherlands, the Industrial Ethernet event was themed “Linking people, companies, and machinery.”

PROFIBUS, PROFINET and IO-Link seminars in UK

PI UK held two “Practical Aspects of PROFIBUS, PROFINET and IO-Link” seminars with accompanying mini fairs in Manchester, which between them attracted over 50 people who listened to presentations covering design, installation, commissioning, fault-finding, safety, and security, plus EMC and Industrie 4.0.

PI UK held two “Practical Aspects of PROFIBUS, PROFINET and IO-Link” seminars with accompanying mini fairs in Manchester, which between them attracted over 50 people who listened to presentations covering design, installation, commissioning, fault-finding, safety, and security, plus EMC and Industrie 4.0.

An analysis of the feedback received indicated that of the attendees at the Factory Automation seminar, 40% indicated that as a result of attending the seminar, they would now be more likely to use, or make greater use of PROFIBUS, while 50% indicated they would be using IO-Link and 70% would be using PROFINET. A similar analysis of the Process Automation seminar delegates indicated 78.6% would be using or making greater use of PROFIBUS and 71.4% would be using PROFINET in their projects.

Industrial Ethernet 2017 Event in the Netherlands

Linking people, companies, and machinery

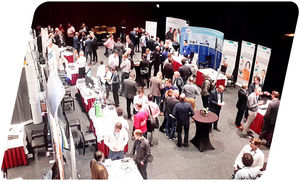

On March 16, the members of FHI and PI Netherlands  together with more than 170 visitors, discussed the possibilities of Industrial Ethernet. The high attendance confirms that the integration of Industrial Ethernet and digital communication is being widely adopted on the factory floor. More than 20 companies presented their solutions and topics in the middle of the Netherlands.

together with more than 170 visitors, discussed the possibilities of Industrial Ethernet. The high attendance confirms that the integration of Industrial Ethernet and digital communication is being widely adopted on the factory floor. More than 20 companies presented their solutions and topics in the middle of the Netherlands.

Mike Balm working for Thales highlighted the relations between different devices at home and at work. Thales is building a platform where everything comes together, so that you do not need to be running different applications on your devices, but only one. They are also busy decentralizing security to ensure safety as much as possible in a flexible environment. Thales handle security not as a big shell, but as individual files, secured separately, also called Content Based Security.

Henk Capoen of Catael discussed important elements in the digital revolution. He began with the change of the PLC, the workhorse of the industrial world, the controller in heavy industrial environments. Over the last few years the PLC has become more and more a communications system. Regarding the question have embedded PC’s conquered the PLC, there is no answer yet. What we have today is that there are more and more features added to both devices. The PLC nowadays can directly communicate with databases, MES, and ERP applications. The choice between a PLC or an embedded PC is still difficult. If you ask this question to an ethical hacker, then maybe you get this surprisingly answer; many hackers often do not understand the language / protocols of a PLC and that makes it less attractive for the ‘standard’ hacker.

In the total program topics addressed included cyber security, the use of fiber, the use of wireless, and IoT and Industrie 4.0. Also we see a major adoption of sensors and automation in the agricultural sector. Two speakers Henk Mesken from the company Mesken with Marcel Tuit from the member company Weidmüller Benelux, presented a large network of redundant machine supply lines, pressing, and packing robots. They were followed by Lely, who finished the day, with a view in the future, which is actually already a reality.

Industrial Ethernet 2017 was very appreciated by the visitors. Behind the scenes, we are already working on the 2018 edition. We hope to see you next year.