Introduction

Whatever the industry, any company that wants to be competitive on an international stage must maximize its production automation level. Flexible and automated production processes are the most essential component for increasing production levels, reducing batch sizes, and ultimately increasing productivity.

The future of intralogistic processes in the field of manufacturing automation is dominated by automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). The role of AGVs/AMRs within the logistics and supply chain industry is becoming increasingly important as they significantly impact productivity, safety and efficiency. To operate at their highest potential, it is imperative that AGVs/AMRs use sensor information effectively to intelligently navigate.

Even though AGVs/AMRs have become a focal point in today’s manufacturing automation industry, they face one key issue: missing interoperability between different types of AGVs/AMRs, location data, and communication interfaces. Historically, different interfaces have made it challenging to effortlessly control and manage third-party AGVs/AMRs, resulting in complex integrations.

omlox has The Solution

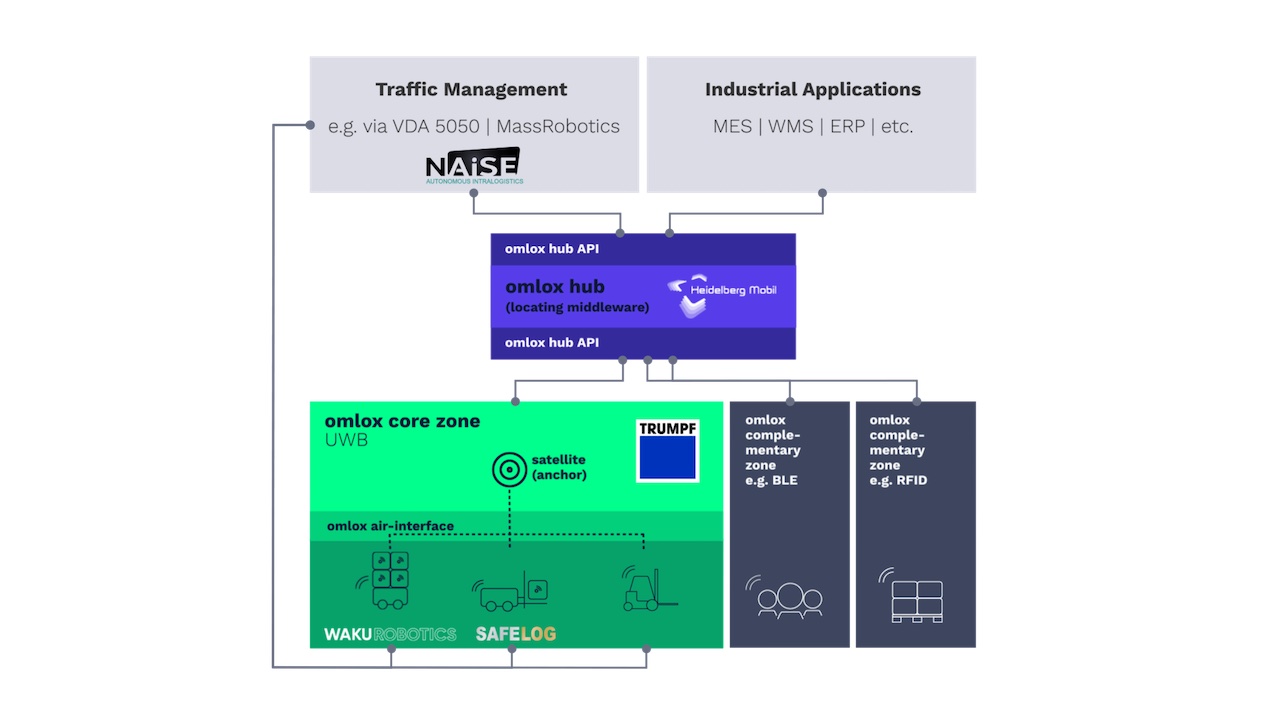

omlox, the world’s first open locating standard, unifies location data from all positioning technologies and enables vendor-independent locating of all moving objects. In the context of AGVs/AMRs, it complements VDA 5050 – a standardized interface for the communication between AGVs/AMRs and a master control (fleet management software). Together, omlox and VDA 5050 ensure interoperability between different types of AGVs/AMRs and fleet controllers.

This interoperability results in a plethora of benefits and enhances processes through optimization. For example, organizations can quickly and flexibly react to order fluctuations by integrating additional AGVs/AMRs when workloads are high, or reducing the number of AGVs/AMRs when workloads are low. With omlox, individual manufacturers and providers can provide the maximum benefit for end users in a manner that is affordable with manageable development costs.

The foundation of omlox is built upon an ecosystem of partners that is growing at a rapid pace. The member companies span a variety of backgrounds – ranging from software and hardware companies, system integrators, and solution providers. They all have one common goal: to utilize, promote, and develop the omlox standard in order to streamline the use of location data and enable new use cases. Ultimately, this will ensure more efficient processes in the manufacturing and supply chain industry.

Although VDA 5050 and omlox both represent highly relevant standards in the industry, they both focus on different areas of standardization. While VDA 5050 was conceptualized to ensure interoperability between AGVs/AMRs and fleet control systems, omlox was subsequently conceptualized to ensure interoperability between different locating technologies. Collaborative work with both standards in the omlox community lead to the realization that combining both standards would extend the horizon of interoperability.

The Arena

To derive a solution incorporating both standards to create an easy-to-implement, flexible and, most importantly, holistic traffic fleet management solution, several key omlox partners teamed up for a joint collaborative project. Here is a short snapshot of the companies involved:

- SAFELOG offers the development and intelligent linking of innovative logistics systems such as AGVs/AMRs.

- TRUMPF Tracking Technologies enables you to create flexible, real-time tracking solutions for tomorrow’s locating requirements.

- Heidelberg Mobil International is a global technology company focused on reshaping how location data is used in IoT.

- NAiSE offers the world’s only traffic manager for all participants of intralogistics.

- WAKU Robotics offers the largest mobile robot comparison website, called Lots of Bots.

The ideal playground for this project was found with ARENA2036 (Active Research Environment for the Next generation of Automobiles) – a research campus located in Stuttgart, Germany, supported by the Federal Ministry of Education and Research (BMBF). It is structured as a registered association representing an innovation platform for cooperation between science and industry with a focus on future mobility.

The ARENA campus is laid out as a versatile factory which serves as an open co-working space. The cooperation through heterogeneous project groups enables the transfer of competencies beyond the boundaries of a single entity, which has a lasting effect on the creation of creative and innovative work. Such a setup facilitates research results outside the established solution spaces to become feasible.

The Use-Case

WAKU Robotics helps with the selection of AGVs/AMRs and brings these robot systems to the factory floor through flexible financing and procurement models. Their Lots Of Bots portal is the largest free and independent comparison platform for mobile robots in the area of logistics and production.

For this project, SAFELOG provided an array of VDA 5050-compliant AGVs/AMRs. Intelligent automated guided vehicles from SAFELOG provide forklift-free and automated JIS and JIT supply for assembly lines and packing stations.

TRUMPF Tracking Technologies supplied the UWB-based omlox core-zone infrastructure, which sets the foundation for an open, real-time locating system. The infrastructure includes a set of anchors, the required tags that are being tracked, as well as the locating software running on an IPC or server to determine the exact position data. The “air interface” of the omlox core zone defines the communication between an anchor and a tag. It is also standardized, meaning that any omlox-compatible UWB tag attached to an AGV/AMR can communicate with the omlox anchors in the core zone – irrespective of the vendor by which it is supplied. This way, an AGV/AMR can be up and running in no time to receive positioning data.

The local positioning data from the TRUMPF core zone (the AGV’s/AMR’s positions) is then sent to the omlox hub. Heidelberg Mobil developed the premier omlox hub implementation – the DeepHub®. The DeepHub is a middleware that acts as the centerpiece of omlox, as it aggregates and processes location data from any source. It transforms local positioning data into standardized, global coordinates, and provides it to any system or application via the standardized omlox API. In this case, the UWB tags from TRUMPF are set up as movable objects in the DeepHub. The location data is aggregated in real-time and the DeepHub computes distances to prevent collisions between AGVs/AMRs and other objects.

The harmonized data from the DeepHub is subsequently sent to the NAiSE fleet management software through the omlox Hub API. Their platform is operated via an intuitive web application that allows for the management and control of the guidance system for the AGV/AMR fleet. Through the omlox standard, the NAiSE fleet management system can incorporate not only AGVs/AMRs, but location data from any other moveable object (people, forklifts, tugger trains, etc.) in traffic control and can therefore ensure seamless material flow in mixed operations.

In addition to the NAiSE fleet management system, the performance of the AGVs can be monitored through WAKU Sense – a platform for alerting and incident management.

Conclusion and Outlook

Setting up a flexible AGV/AMR fleet management system is a challenging task, particularly if you aim to track devices from different vendors and add additional devices to cope with changes in workload on demand. The solution derived from this project has shown how simple it can be to integrate and manage different devices into one holistic system with the help of a global standard that enables full interoperability.

Standards such as omlox and VDA 5050 enable a fast and lean integration of AGVs/AMRs into a new environment. These industry standards are the solution to overcome the limitations of proprietary systems, making location solutions for smart factories and Industry 4.0 realistic and most importantly affordable.

omlox provides streamlined access to location data not just of AGVs/AMRs, but any trackables throughout a facility, such as human-operated machinery and workers. This granular overview of the entire facility allows for true optimization of production processes.

New and innovative solutions are seldomly achieved by a single effort and often involve like-minded people with the same drive coming together. This is what makes omlox unique: its ecosystem of specialized and forward-thinking partners that fosters collaboration at the highest level. Innovation is taking existing solutions and putting them together in a new way and it comes from creating the right environments where ideas can connect.