During the last few years, industrial communication systems based on Ethernet (PROFINET mainly) have spread immensely. Transitions toward innovative technologies require huge investments: purchase of new field devices, new cabling and higher-performance processors. For many companies, the investment in new protocols is not a real necessity and can be postponed by investing in the existing plant.

But what are the tricks to extend the life of an existing PROFIBUS network? And what kind of investments are required?

1- Follow the ‘PROFIBUS Installation Guideline for Cabling and Assembly’ rules, defined by PI International.

Basically this means:

- Check the installation of active terminations at the end of each segment and check the related power supply. Some devices have their own integrated terminations; however, we recommend including active terminating resistors to avoid any issues when disconnecting a device from the power supply or when it is taken out of the network. The price of an active termination depends on the brand and its characteristics, however it is a relatively small investment.

- Respect the cabling rules (i.e. the one-meter rule) and use certified PROFIBUS cables. Remember that cables are subject to wear and tear and ensure that cables are not too close to EMC-sensitive areas (e.g. power cables or motor drives).

- Make sure that the PROFIBUS connectors are properly connected.

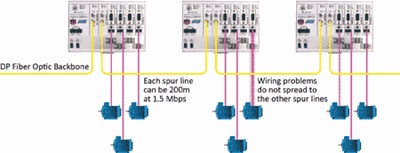

- To avoid interference and disturbances, remember to separate the segments with disturbances using repeaters or Fiber Optic. EMC interferences can damage the plant, limiting its functioning and reliability, increasing the costs related to maintenance or troubleshooting.

- Check if any configuration error occurs.

2. Adequate technical training

Every company should have at least one Certified PROFIBUS Engineer or Certified PROFIBUS Installer working. A Certified Engineer should keep up-to-date with the latest innovations and changes in the fieldbus technology. For example, in the last few years some PROFIBUS rules have been outdated by some recent innovative products launched on the market. In some regions, needed investments in technical training is paid by public funding or allowances.

Only trained technicians can easily understand the reasons of malfunctioning or solve issues that happen in their networks. Engineers who do not know the rules of PROFIBUS will often try to solve issues using the wrong instrumentations and spend money on unsuitable solutions. For instance, checking the information provided by the PLC does not suffice, similar to replacing cables or devices when these are not the reason of the malfunctioning.

The big question now is what is less costly:

- Not investing in training and risking a wrong or inappropriate decision.

- Spending a limited amount of money for Certified Training and have the right people for the job with the specialist knowledge to always find the best solution.

3- Recurring diagnostic activities.

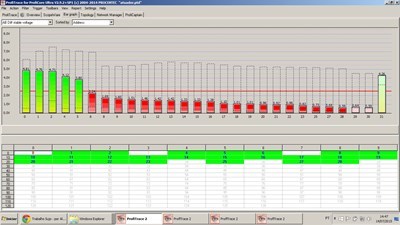

Diagnostics of the PROFIBUS network requires a protocol analyzer and an oscilloscope. ProfiTrace combines those functionalities in a single mobile tool. Many Competence Centers and experts use this powerful tool worldwide. Auditing the PROFIBUS network is important to find errors or issues.

At the end of the audit, it is important to generate a report with the analysis of the protocol and an overview of the issues and data at a certain moment. If an issue occurs only sporadically and it is hard to detect, we recommend installing a permanent monitoring tool for predictive maintenance. Due to these kind of tools, the company can save the money typically spent on safety protocols and maintenance work in the field.

4- Ask a PROFIBUS expert!

A PROFIBUS expert can provide technical support on site and check the health of the network, suggesting the right solution to a problem.

The experts have all the specialist knowledge and tools for repairing breakdowns directly on-site, usually in less than one day. After the testing phase, the experts provide a report with the protocol analysis and give specific recommendations on how to improve the quality of the network.

In conclusion… these four tricks require moderate investments and provide solutions to extend the life of a PROFIBUS installation, avoiding downtimes and high costs for urgent troubleshooting and maintenance. Many companies have experienced downtimes and breakdowns costing thousands per hour. This can easily be avoided with moderate expenditures by following the four tips in this article.

Managing Director

PROCENTEC Italy