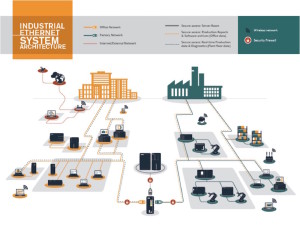

There are numerous advantages to using Ethernet on the plant floor and some critical issues to consider for a successful implementation: migration strategies, communications differences, security needs, and the need for industrially hardened devices. Here are the five critical things an IT Professional needs to know about bringing Ethernet to the plant floor.

CLICK HERE TO READ THE WHITE PAPER

Major manufacturers like automotive are moving exclusively to Ethernet. Why? For one reason, it allows an entire assembly line to be on one physical network, and enables the ability to plug in anywhere and access any node on the network. This is a huge step forward from days past, when companies had a collection of isolated fieldbus networks, one at each machine. With Ethernet they get a unified network that is far easier to manage.

Major manufacturers like automotive are moving exclusively to Ethernet. Why? For one reason, it allows an entire assembly line to be on one physical network, and enables the ability to plug in anywhere and access any node on the network. This is a huge step forward from days past, when companies had a collection of isolated fieldbus networks, one at each machine. With Ethernet they get a unified network that is far easier to manage.

From an architectural perspective, the design is simpler and cleaner, making troubleshooting easier and giving users the ability to log on from anywhere. Once connected, tools can be used to see if a node is responsive, and to harvest detailed data for better decision making. Bottom line: bringing Ethernet onto the plant floor opens the door to engineering capabilities that current fieldbus networks can’t handle, from the free flow of production data to simplified device monitoring and maintenance. There are a few issues, however, that IT staff should keep in mind as they make the move.