Use PROFINET Switches to Increase Diagnostic Capabilities and Reduce the Time to Market

Project Introduction

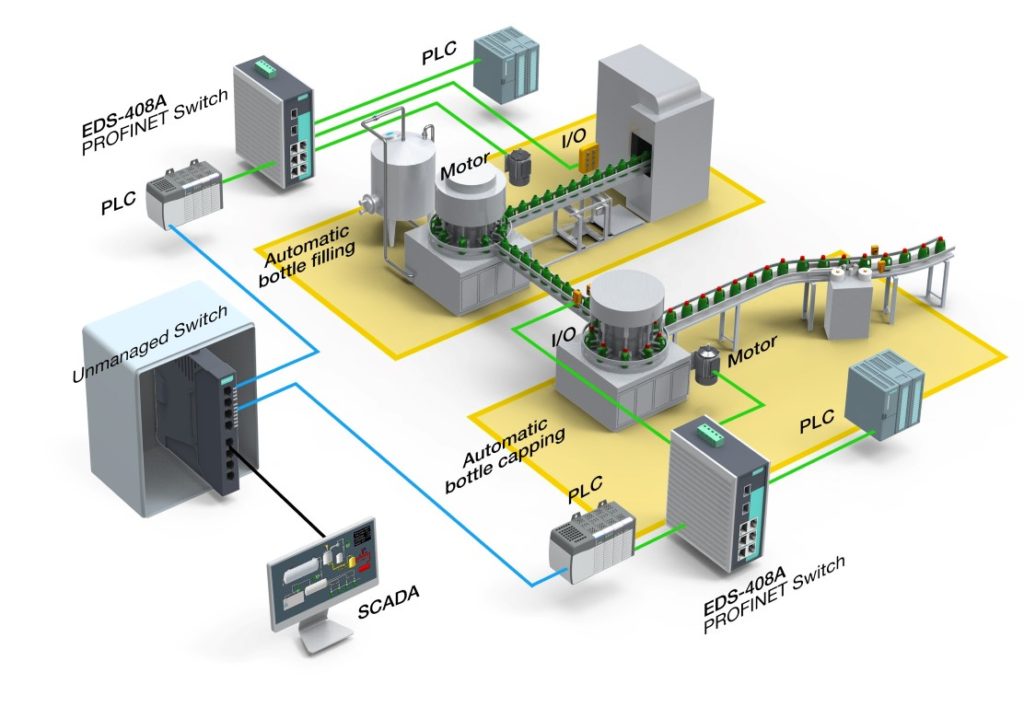

A Moxa customer, one of the leading manufacturers of filling, bottling, and packaging machines utilizes Ethernet switches and PROFINET technology to create an integrated industrial network for all of their machines. Learn why this customer chose to deploy Moxa’s devices in order to enhance production efficiency at their bottling plant.

The use of the PROFINET protocol is becoming a de-facto standard in manufacturing. However, before all of the benefits of Ethernet-based technologies can be exploited, machine builders have to overcome a few challenges. One of the main challenges is that machines builders often come from a technical field of mechanics and electrical engineering and do not have much IT knowledge so they find it difficult to work with the new IT infrastructures that are currently being deployed. This manufacturer, based in Europe, is already using the protocol in its machinery and equipment. By using PROFINET, the company can increase the diagnostic capabilities of their PLCs, reduce the time it takes to build their machines, and can enable untrained staff to replace devices within a few minutes.

System Requirements

The migration from PROFIBUS to PROFINET requires minimal electrical engineering knowledge, but new IT knowledge in order for a smooth transition to take place. The company invested in an exclusive PROFINET division early on because they realized the potential of migrating to PROFINET and wanted to reap the benefits as early as possible. Companies that do not utilize PROFINET technology often have to go to the plant to check on a device and manually enter the IP address and the name of the PROFINET device. As downtime at a bottling plant is very costly, engineers often have to go to the site immediately in order to keep downtime to a minimum.

To take full advantage of the benefits of PROFINET, the company deploys field-proven Ethernet switches that form an internal network. Within the internal network, Ethernet-based devices that communicate on a machine level are integrated with other packaging machines on the factory level, and are controlled and monitored from a decentralized control center. As the process of fixing machines is very simple, even untrained staff can get the machine operating normally again quickly. In addition, it is important that the centralized control function of the control system performs reliably all the time. The company also builds machines for the beverage, chemical, and health care industries, so it is essential that every piece of machinery can withstand high-pressure cleaning solutions and sterilizers.

Moxa Solution

High Performance on PROFINET networks

One of the manufacturer’s solutions is a filling line for soft drinks that consists of three machines: a filling machine, a labeling machine, and a packaging machine. To control the machinery, the manufacturer uses Siemens S7-1500 PLCs. The PLCs are responsible for ensuring that all adjustable drives, HMIs, actuators, and sensors function properly. For the filling machine solution to work properly, the PLCs require managed switches that support the PROFINET protocol. In addition, the switches must also act as a cyclic PROFINET I/O device. The company is able to meet all of the key project requirements by deploying Moxa’s EDS-408A-PN, which is a managed switch that is capable of cyclically exchanging information with the S7-1500 over the PROFINET protocol. The machine builder only needs to load the GSD file into the PLC, and does not need to perform any more configuration. The PLC can automatically correct the name of the PROFINET device if it is not assigned correctly. This simplifies the first steps of machine development and saves the manufacturer time. In addition, the managed switch can exchange information between adjacent devices using LLDP (Link Layer Discovery Protocol), which enables PROFINET DCP (Discovery and Configuration Protocol) in accordance with the IEC 61158 standard.

The PROFINET switches can be integrated into the PLC using SIMATIC Step 7 or the TIA portal. This allows the PLC to determine which ports are active, if the redundancy mechanisms and redundant power supplies are working, and what the data transmission speed is. The PLC can evaluate this information or pass it on to the HMIs. The information can be integrated directly in the programmer’s development environment, which generates added value for programmers and end users without the need for additional tools or interfaces.

Fixed Topology

The machine builder deploys networks with fixed topologies, which means star, ring, tree, and mixed structures can be used. When every network node is attached to a fixed, physically defined port, the network can perform the configuration by itself. In this scenario, all PROFINET devices know the name of each PROFINET device and what device is communicating with what device across the network. Manufacturers that do not use a fixed topology network will often only realize there is a problem when the system fails. This is very problematic because the machine builder must send an engineer to the plant to configure the devices with special automation software in order to get the device working again. One of the main advantages of using a fixed topology is that untrained staff can simply replace devices. There is no need to configure devices as this is done automatically by the switch and the PLC, which removes the need for a skilled engineer to manually assign IP addresses and name the PROFINET device.