Reliable automation concept with PROFINET technology for compact packaging machine

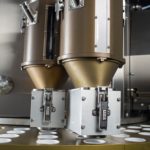

Gima SpA is an Italian manufacturer of packaging machines with many years of experience in the field of innovative packaging solutions, including the food industry. With the 590 series, the company has expanded its machine range for filling and packaging soluble products such as coffee or tea capsules. The machine offers benefits including low entry costs and was developed especially for low and medium production volumes. The Gima 590 not only fills a gap in the midrange market, it is also ideal for large end customers who often want to test new mixes or products – at packaging speeds of 100 to 200 capsules per minute. The new machine is a rotary packaging machine, which means its moving units have been implemented by means of rotary, non-linear workstations.

Adaptable to the customer

A benefit of the new 590 series lies in its compact design, since its construction volume has been reduced by 70 percent compared to a traditional linear machine. Because the new packaging machine is modular, it can easily be adapted to customer-specific production requirements. The mechanical submodules are easily and quickly exchanged, thus considerably simplifying the maintenance work that is usually required for large machines. The floor space is only slightly more than four square meters, which means that the machine can easily be moved without having to dismantle it completely. The time for commissioning is therefore significantly reduced.

Technology for precise production

The automation concept is literally the intelligence of each machine. In the case of the Gima 590, it is completely based on Siemens technology. Davide Azzolini, Head of Electrical Engineering at Gima SpA, explains: “We chose Siemens technology in the development of the 590 series for a number of reasons. Above all, the performance and flexibility of the Simotion D motion control system was decisive for us. In a single development environment, we were able to implement the complete machine automation, starting with typical motion control functions and axis handling down to the drive technology and the motors.”

The automation concept is literally the intelligence of each machine. In the case of the Gima 590, it is completely based on Siemens technology. Davide Azzolini, Head of Electrical Engineering at Gima SpA, explains: “We chose Siemens technology in the development of the 590 series for a number of reasons. Above all, the performance and flexibility of the Simotion D motion control system was decisive for us. In a single development environment, we were able to implement the complete machine automation, starting with typical motion control functions and axis handling down to the drive technology and the motors.”

The PROFINET Piece

All automation components are linked via Profinet and complete remote Internet access to the automation components is implemented via a secure SSL VPN connection.

Thanks to the completely Profinet-based network, it is easy to carry out special or detailed diagnoses of all the components used in the network. The web server available in the automation components offers additional benefits: No additional development tool is needed to access system data, for example. In addition to communication, another decisive benefit of Profinet is the “Safety Integrated” function. Safety Integrated (Profisafe) saves space in the control cabinet, which is very limited due to the compact design of the machine, and cabling is significantly reduced. It is thus an integrated solution that is perfectly adapted to the compact machine.

Conclusion: a strong partner

Gima is an excellent partner in the packaging industry that always has new custom solutions and is still very satisfied with the decision for Siemens as a technology partner. “In addition to its deployment of state-of-the-art technology, we have found Siemens to be a partner who is a specialist in packaging machinery technology, knows the specific requirements of the sector, and is rapidly implementing them,” Azzolini concludes.

Author: Andreas Seubert, Siemens AG