Cooperation between PROFINET and OPC UA

PROFINET’s OPC UA companion specification is set to be reviewed soon. The solution’s user-friendliness has already been tested in terms of its practical implementation, using the example of a multi-vendor demonstrator; at the PI booth at SPS IPC Drives 2018, multiple applications were shown in interaction with PROFINET and OPC UA.

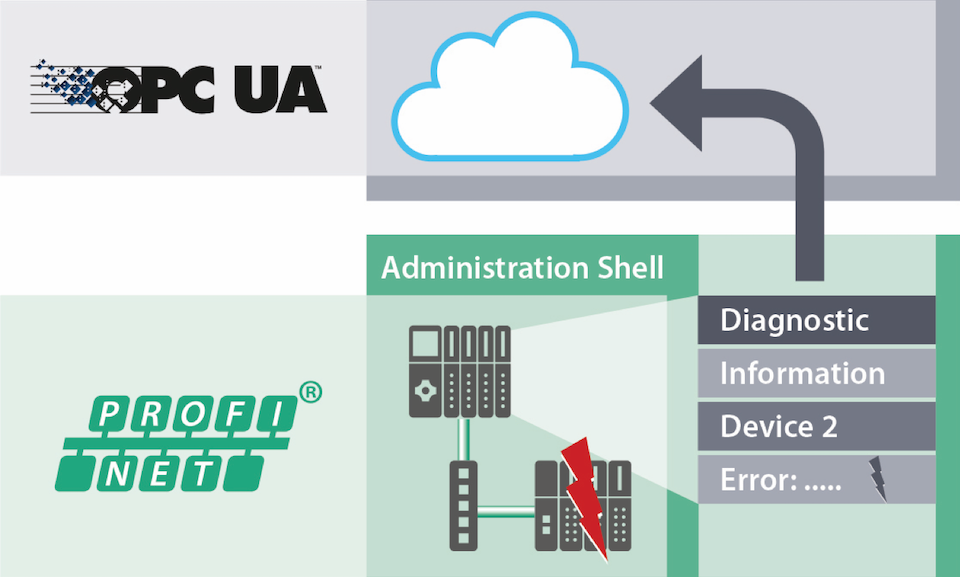

According to extensive coordination talks with users, the most significant content of PROFINET’s OPC UA companion specification includes the collection and display of asset management and diagnostic data. This information can be displayed flexibly in specific ways on various devices, based on the requirements and possibilities.

Asset and diagnostic data from the devices employed today can be collected in a system controller through existing mandatory PROFINET services and delivered to higher-level entities by means of OPC UA. This service can also be offered by an edge gateway, which can additionally be added to the system. The advantage here is that no changes have to be carried out on the controller. These use cases are predestined for innovating characteristic brownfield systems. It is also possible to directly integrate the OPC mapping in a PROFINET field device. In this OPC UA use case, which is in demand by customers, the basic characteristics of PROFINET are once again proving to pay off – specifically, PROFINET’s openness for parallel TCP/IP communication and its comprehensive structuring of data.

These possibilities lay the foundation for further applications, such as the implementation of an own OPC UA modeling (e.g. for collecting energy data) or of standardized models (e.g. Namur Open Architecture [NOA]).

During the drafting of the companion specification, the experts’ discussions concerning the existing and planned applications raised a fundamental architectural question in relation to different OPC UA implementations in a device or system: How can different aspects of a device – such as the hardware view, technology view and communication view – be coherently displayed in a way that is useful and comprehensible for the user? This issue will lead to extensions of the OPC UA basic specification; it demonstrates that PI is bringing significant improvements in the OPC UA basic specification to the Foundation, while PI’s expertise is also contributing to OPC UA’s suitability for industrial applications.

With their combined forces, PROFINET and OPC UA are already in a position to offer added value to customers and will integrate new possibilities – such as TSN – in the future. “In the coming years, we want to further intensify our longstanding cooperation with the OPC Foundation – a partnership that has yielded technologies such as FDI,” emphasizes Karsten Schneider, Chairman of PI. “We can mutually benefit from each other’s expertise, thereby facilitating Industry 4.0 in the field of communication.”

Sensor-to-Cloud with IO-Link via OPC UA

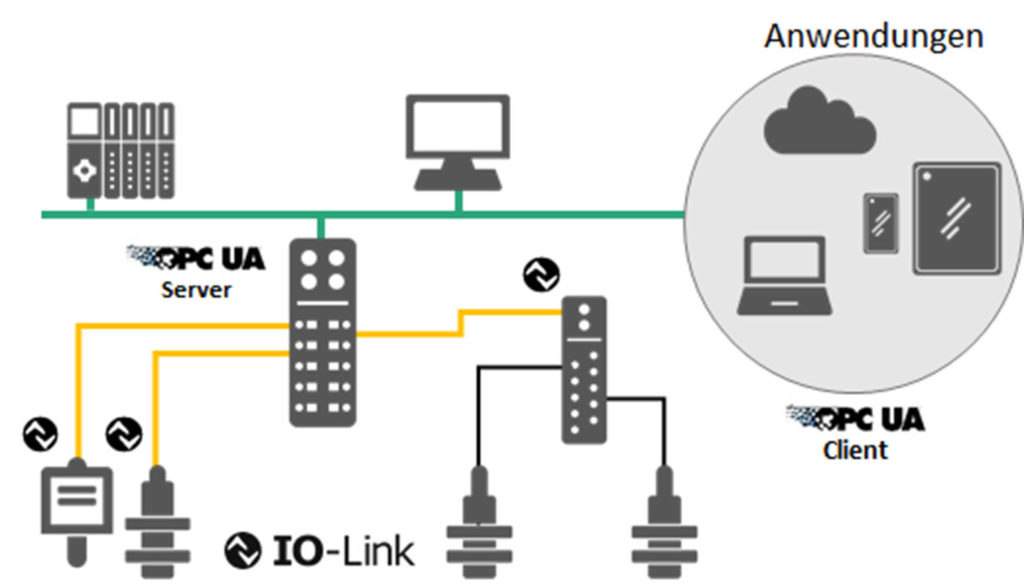

IO-Link was originally developed in order to provide easy standardized wiring of intelligent, complex sensors and actuators using a simple three-core sensor cable. As the issues surrounding Industry 4.0 grew more specific, it quickly became clear that IO-Link is the key in implementing powerful Industry 4.0 concepts, since a wide variety of field information is required from production plants.

Besides the control of automated production and device configuration, this information is increasingly needed for remote maintenance, asset management, predictive maintenance, condition monitoring, and data analytics in order to optimize production and make it more flexible. These tasks are based on open sensor-to-cloud communication. Having completed IO-Link’s safety and wireless technological features, the IO-Link Community undertook this new challenge and – in cooperation with the OPC Foundation – began working on a companion specification, “OPC UA for IO-Link.” The decision in favor of OPC UA was the result of the widely accepted standardized semantic description of the data to be transmitted as well as its relation to the “language” of automation.

In an initial step, main application cases were defined in an IO-Link working group that represented over 20 companies. This formed the basis for drafting the companion specification, in cooperation with experts from OPC UA. The contents were derived from the OPC Foundation specification “OPC UA Device Interface,” which contains the generic model of a field device. The underlying architectural model guarantees conformity with all other field devices that are based on OPC UA.

This companion specification passed a review by the IO-Link Community and the OPC Foundation; the final version V1.0 was then drawn up and adopted. The first implementations and examples were prepared for the SPS IPC Drives trade fair in November 2018.

An IO-Link Community working group then began the task of defining the JSON data-interchange format for IO-Link; defining this internationally recognized data format would allow for configuration tools to be connected independent of manufacturer and for lean sensor-to-cloud applications to be implemented.