Open solutions have always been the trademark of PI technologies. The PI Organization follows this credo both in the integration of TSN (Time-Sensitive Networking) into PROFINET and the presentation of PROFINET data in the OPC UA object model. The result is a user-friendly solution which can be used for future architectures and which shows its potential in many brownfield systems as well.

Beneficial Cooperation

Effective communication isn’t just extremely important on the technology side – users profit when it occurs between different user organizations as well. A good example of this was provided through the cooperation of experts from PROFIBUS & PROFINET International (PI) and the OPC Foundation, which recently specified a solution for the presentation of PROFINET data in the OPC UA object model at a joint working group. This means that, with their combined forces, PROFINET and OPC UA are already in a position to offer added value to customers and will integrate new options – such as TSN – in the future.

Companion Specification Use Cases

The most significant content of PROFINET’s OPC UA companion specification includes the collection and display of asset management and diagnostic data. “This makes it possible to concretely implement different applications depending on the requirements and options in a very flexible way,” explained Karsten Schneider, Chairman of PI (PROFIBUS & PROFINET International). Asset and diagnostic data from the devices employed today can be collected in a system controller through existing PROFINET services and delivered to higher-level entities by means of OPC UA. This service can also offer an edge gateway, which can be used as an additional application on the system. “The major advantage here is that no changes have to be made on the controller. That makes these use cases virtually predestined for innovating brownfield systems,” continued Schneider. It’s also possible to directly integrate OPC mapping in a PROFINET field device. In this OPC UA use case, the basic characteristics of PROFINET are once again proving to pay off – specifically, PROFINET’s openness for parallel TCP/IP communication and its comprehensive structuring of data. These possibilities also lay the foundation for further applications, such as the implementation of individual OPC UA modeling (e.g. for collecting energy data) or of standardized models (e.g. Namur Open Architecture [NOA]).

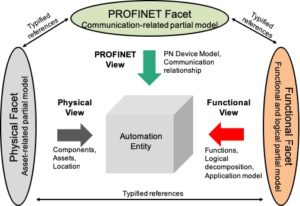

Different Views Under OPC UA

“During the drafting of the companion specification, the experts’ discussions concerning the existing and planned applications raised a fundamental architectural question in relation to different OPC UA implementations in a device or system. With OPC UA, the aspect of different views had previously been lacking – how could hardware, technology and communication be represented coherently and in a way which is comprehensible for the user? This is now being introduced to the expansions of the basic OPC UA specifications,” added Schneider.

“During the drafting of the companion specification, the experts’ discussions concerning the existing and planned applications raised a fundamental architectural question in relation to different OPC UA implementations in a device or system. With OPC UA, the aspect of different views had previously been lacking – how could hardware, technology and communication be represented coherently and in a way which is comprehensible for the user? This is now being introduced to the expansions of the basic OPC UA specifications,” added Schneider.

Practical Transition from Old to New Technology

That’s not enough, though. There’s TSN homework to be done, too. “It can’t be stressed enough that the most important aspect is that the user wants to continue using their tried-and-tested PROFINET applications and existing architecture. The transition to the new technology still has to be manageable by the user,” emphasized Schneider. To arrive at a sustainable solution, PI first chose three TSN mechanisms which are especially important for the requirements for real-time transmission in automation. This includes:

- Time synchronization

- Enhancements for scheduled traffic

- Frame preemption

These are typically the same principles which apply for IRT (isochronous real time), or as Schneider put it, PI set the right course in the past. Existing architectures can easily continue to be used with TSN thanks to this. Practical testing has also been carried out here as well, where a demo system comprised of a variety of available TSN hardware components and PN stacks was tested for network synchronization, IO synchronization, integration of existing devices and network load. It was shown that real-time-capable IO applications with a jitter of less than 1 µs is just as possible as plug-and-work during network changes. The easy connection of existing PROFINET devices and the robustness of PROFINET communication, even with high network loads, were also demonstrated. The specification work for this has been completed as well.

These are typically the same principles which apply for IRT (isochronous real time), or as Schneider put it, PI set the right course in the past. Existing architectures can easily continue to be used with TSN thanks to this. Practical testing has also been carried out here as well, where a demo system comprised of a variety of available TSN hardware components and PN stacks was tested for network synchronization, IO synchronization, integration of existing devices and network load. It was shown that real-time-capable IO applications with a jitter of less than 1 µs is just as possible as plug-and-work during network changes. The easy connection of existing PROFINET devices and the robustness of PROFINET communication, even with high network loads, were also demonstrated. The specification work for this has been completed as well.

Outlook: This is only a cross section of the variety of upcoming work for next year. The topics of security and semantics will be prominent, and the “Safety over OPC UA on PROFIsafe” specification will be published soon as well. Each of these work packages is a crucial component providing answers to questions about what the architectures of the future will look like.

Q&A with Karsten Schneider, Chairman, PI

Question: The “fieldbus war” has finally come to an end after more than 30 years. The “end” of this war was already attempted a good 15 years ago with the emergence of Ethernet – the founding and disbanding of the IAONA – but the vested interests were too great. How different is the current course of the OPC foundation for finally realizing the dream of a uniform communication solution?

Question: The “fieldbus war” has finally come to an end after more than 30 years. The “end” of this war was already attempted a good 15 years ago with the emergence of Ethernet – the founding and disbanding of the IAONA – but the vested interests were too great. How different is the current course of the OPC foundation for finally realizing the dream of a uniform communication solution?

Schneider: To me, the supposed fieldbus war has already been over for 10 years. While work was being carried out on FDI, a new awareness developed during cooperation with other user organizations like the Fieldbus Foundation and HART, as well as with users like Namur. This period facilitated understanding of one another and laid the cornerstone for further cooperation, such as with CC-Link, the OPC Foundation and the OVDA for the intrinsically safe APL Ethernet project. Apart from that, I’m convinced that the competitive situation at the time was definitely positive for technological development. A host of different ideas were brought to market and tried out in practice. This resulted in good technology being available to the user today. In contrast, I see the dream of a uniform communication solution for every requirement as being somewhat more realistic. OPC UA also has competition, for example, and manufacturers will continue to operate different protocols on a network. This is why we will be discovering even more protocols in the future, in addition to the installed base. Who knows what technological challenges we will be faced within a few years. We – and I’m speaking for PI here – are successful when our customers are able to use different manufacturer protocols with no integration problems.

Question: To what degree does PI (PROFIBUS & PROFINET International) have to change to come to a compromise with everyone involved?

Schneider: Actually, the hurdles were considerably higher 10 years ago, compared to today. Since then, we’ve learned to advance the technology together with one another. That’s why there weren’t any noteworthy obstacles this time. Instead, the primary task was to give users an easy-to-handle, sustainable solution.

Question: Nevertheless, they’re still competing, of course. How would PI like to be positioned in the OPC UA over TSN environment?

Schneider: We can see the advantages with PROFINET, especially in the enormous size of the installed base. We have more than 80 million devices with PI technologies in the field. With TSN, it’s now possible to implement real-time applications on a convergent network. It should be stressed here, however, that control will continue to use PI technologies – and we’ve compiled important requirements in the past in this area for redundancy, asset management functions and semantic issues, for example. What’s especially important for the user is our demonstration that the combination of TSN and OPC UA with PI technologies works. This means that we already offer a practical approach for using the new technologies without giving up tried-and-tested ones. Our architecture is open to every possibility.

Question: What message are you sending to your member companies with regard to the advantages and benefits it will have for them and their customers?

Schneider: For our members and customers, it’s investment protection and sustainable technological development which are the absolute crucial aspects we take very seriously. It’s just as important to our member companies and customers that they can continue deciding for themselves which technology is right for them – in other words, which is most effective or affordable. This means that we will continue working to make sure that our technologies remain open. The goal is to have a harmonized network at some point. The initial situation for this is very good, since we got started with the necessary work early on. At the most recent SPS fair, we showed that the combination of PROFINET and TSN works how we and the users envision it. Just to name two examples. The technology worked even with high network loads, and interoperability is guaranteed.

Question: Industrial Ethernet networks have only just overtaken traditional fieldbuses. How long do you think the process will take until OPC UA over TSN takes the lead? In other words, when is successful market penetration of the TSN standard predicted to occur?

Schneider: I think it’s important to be realistic here, too. It took 15 years for the number of newly installed PROFINET nodes to overtake PROFIBUS. Despite the fact that IO-Link had essentially no competitors, it took 10 years for the technology to become established. We should also give TSN technology time like this so that users are provided with a good solution. Naturally, TSN will be on the market faster – corresponding chips will be available next year. The standardization process will be complete in 2022, and experience has shown that the first prototypes and devices will appear on the market shortly thereafter.