Industry 4.0 Requirements

The benefits of Industry 4.0 are based on leveraging increased data for better decision making. Timely access to the data and the delivery of that data throughout the automation system hinges on the connectivity network. Networking technology must evolve to handle the increased data volume, as must the manufacturers’ processes and methodologies.

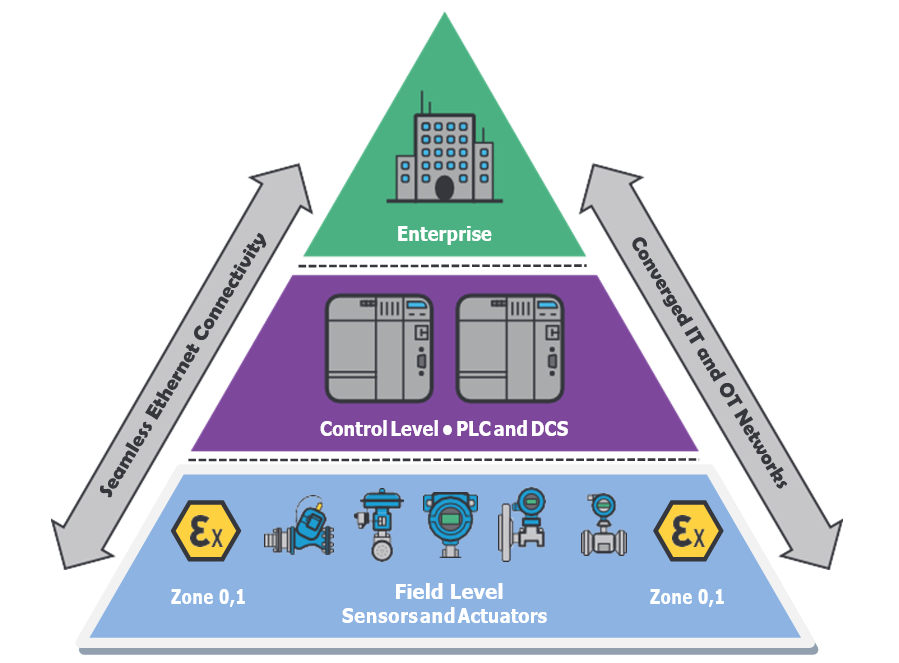

An intelligent, interconnected automation environment requires digitally connected systems and devices, creating and sharing information. How these devices communicate and the manufacturing communications network they use is at the heart of the Enterprise and the enabler for our Industry 4.0 ambition. There is a need for seamless connectivity from every sensor and actuator across the manufacturing site. However, this is not possible today with existing legacy communications.

The challenge becomes finding a way to enable a long reach, higher bandwidth connection to edge devices with increased power availability, without the need for gateways while including hazardous location use. PROFINET on long reach single pair Ethernet (SPE), will provide seamless Ethernet connectivity from the Enterprise to the Edge on a converged network to unlock the benefits of Industry 4.0.

10BASE-T1L

10BASE-T1L is a new Ethernet physical layer standard (IEEE802.3cg-2019) that was approved within IEEE on Nov 7th, 2019. It will change the manufacturing industry by significantly improving plant operational efficiency through seamless Ethernet connectivity to field level devices (sensors and actuators). It solves the challenges that, to-date, have limited the use of Ethernet to the field. These challenges include power, bandwidth, cabling, distance, and use in hazardous locations (intrinsically safe zones). By solving these challenges for both brownfield upgrades and new greenfield installations, 10BASE-T1L enables new insights that were previously unavailable. For example, it enables the combining of process variables, secondary parameters, and asset health feedback while seamlessly communicating them to the control layer without the need for any gateways. These new insights will awaken new realms of possibilities for data analysis, operational insights, and productivity improvements through a converged Ethernet network from the field to the Enterprise.

Both power and data need to be provided to the sensors and actuators to replace 4 mA to 20 mA or fieldbus communications (such as PROFIBUS PA) with 10BASE-T1L in process automation applications. The distance between field-level devices and control systems in process automation applications has been a significant challenge to existing Industrial Ethernet physical-layer technologies limited to 100 m. With distances of up to 1 km required in process automation applications combined with the need for low power and robust field devices suitable for use in Zone 0 (intrinsically safe) applications, a new approach to realize Ethernet physical-layer technology for process automation was required. 10BASE-T1L is this new approach.

10BASE-T1L physical-layer is a full-duplex, dc-balanced, point-to-point communication scheme with PAM 3 modulation at a 7.5 MBd symbol rate, 4B3T coding. It supports two amplitude modes: 2.4 V peak for up to 1000 m cables, and 1.0 V peak for reduced distances. The 1.0 V peak amplitude mode means that this new physical-layer technology can also be used in the environment of explosion-proof systems (Ex) and meet the strict maximum energy restrictions. 10BASE-T1L enables long-distance transmission on two-wire technology of both power and data over a shielded, single twisted pair cable. It belongs to the family of single-pair Ethernet media (SPE).

Ethernet-APL

Ethernet-APL (Advanced Physical Layer) specifies the detailed description of the application of Ethernet communication to sensors and actuators for the process industry and will be published under the IEC. The leading companies in process automation are working together under the umbrella of PROFIBUS & PROFINET International (PI), the ODVA, and FieldComm Goup to make Ethernet-APL work across Industrial Ethernet protocols and to accelerate its deployment. Ethernet-APL specifies the implementation and explosion protection methods for 10BASE-T1L use in hazardous locations.

PROFINET and 10BASE-T1L

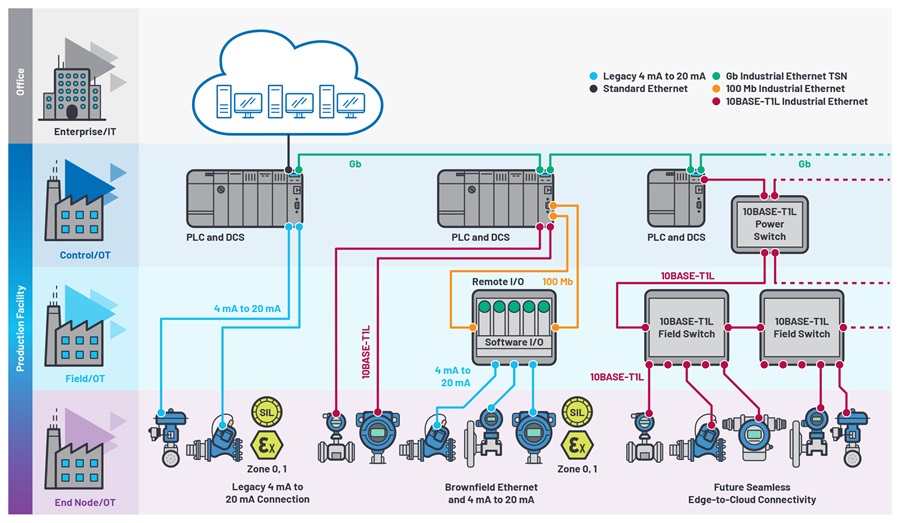

The figure below shows a transition from legacy 4-20 mA connected instruments to a brownfield Ethernet where new, higher power 10BASE-T1L enabled instruments will co-exist with legacy 4-20 mA instruments. Software configurable I/O connects these legacy instruments where remote I/Os provide the aggregation point to a 100Mb Ethernet uplink to the PLC. In the future, seamless Edge-to-Cloud connectivity with PROFINET will be achieved in Process Automation with 10BASE-T1L technology. This approach will remove the need for gateways and I/O, and where Ethernet packets move from the field level to the control level and eventually to the cloud. Also, this strategy realizes the ambition of an Industrial 4.0 unified PROFINET network with IP addressability to each device, dramatically simplifying the installation, configuration, and maintenance of field-level instruments and unlocking their rich datasets.

Topology and Infrastructure

The proposed network topology for 10BASE-T1L in Process Automaton is referred to as a trunk and spur network topology. The trunk cables can be up to 1 km in length with a PHY amplitude of 2.4 V peak and reside in Zone 1, Division 2. The spur cables can be up to 200 m in length with a PHY amplitude of 1.0 V peak and reside in Zone 0, Division 1.

A power switch resides at the control level, providing Ethernet switch functionality and supplies the power to the cable (over the data lines). Field switches reside at the field level in the hazardous area and are powered from the cable. The field switches provide the Ethernet switch functionality connecting the field-level devices on the spurs to connect to the trunk and pass the power to the field-level devices. Multiple field switches are connected on a trunk cable to provide for the high numbers of field-level device connections to the network. Also, the field switches can be connected via a ring topology to enable redundancy.

Performance

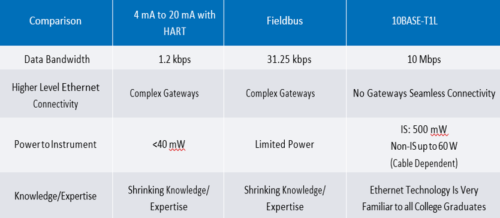

At the Edge, a data rate of 10 Mb/s is a significant advance for most applications that previously were limited to a data rate of roughly 30 kbps, or even less. When it comes to power delivery to field devices, 10BASE-T1L can deliver up to 500 mW in Zone 0 intrinsically safe applications, compared to that of approximately 36 mW delivered by 4-20 mA systems today. In non-intrinsically safe applications, up to 60 W of power is possible depending on the cable used.

With significantly more power available at the Edge of the network, new field devices with enhanced features and functions can be enabled because the power limitations of 4-20 mA and fieldbus no longer apply. For example, higher performance measurement and enhanced edge processing of data are now possible with this additional power.

By converging on 10BASE-T1L, the need for expensive, complex, and power-hungry gateways has been removed. By removing these gateways, the cost and complexity of these legacy installations decreases, and data islands are avoided. Process automation applications, to-date, have used the legacy communication standards as shown in the table below, which have several limitations that the new 10BASE-T1L standard overcomes.

Implementation

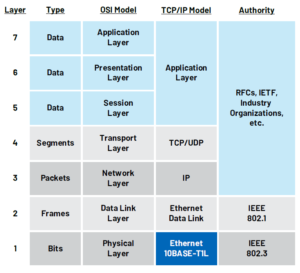

Ethernet standards ensure that all higher protocol layers with 10BASE-T1L work exactly as with 10BASE-T, 100BASE-TX, and 1000BASE-T, eliminating the need for sophisticated gateways. IEEE 802.3 defines all physical layers in the ISO 7-layer model for Ethernet: 10BASE-T1L.

Ethernet standards ensure that all higher protocol layers with 10BASE-T1L work exactly as with 10BASE-T, 100BASE-TX, and 1000BASE-T, eliminating the need for sophisticated gateways. IEEE 802.3 defines all physical layers in the ISO 7-layer model for Ethernet: 10BASE-T1L.

To communicate with a 10BASE-T1L enabled device, a host processor with integrated medium access control (MAC), passive media converter, or a switch with 10BASE-T1L ports is required. No additional software, no customized TCP/IP stack, and no special drivers are required. The combination of PROFINET with 10BASE-T1L physical layer will provide seamless Ethernet connectivity from the Enterprise to the Edge on a converged Ethernet network to unlock the benefits of Industry 4.0.

Maurice O’ Brien

Strategic Marketing Manager

Industrial Communications

Analog Devices

Volker Goller

System Applications Engineer

Deterministic Ethernet Technology

Analog Devices