New Video: PROFINET and Edge Computing

The Edge Concept

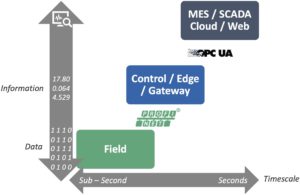

Edge components are key enablers for vertical integration. They can be existing network devices with edge capabilities or external devices added to the network. In both cases, the edge components gather data from the factory floor. Then, they turn it into valuable information for higher-level systems.

Device-2-Cloud Communication

OPC UA has become the de-facto standard for interoperable information exchange from the shop floor to the top floor (vertical communication). With its robust object-oriented information model and platform independence, OPC UA is proving to be the most efficient way to move semantic information around a plant. This fits perfectly with PROFINET with its ability to run different protocols independently on the same Ethernet network. OPC UA is a perfect aid to boost vertical integration in PROFINET systems and to bring added value to end-customers.

Example: OPC UA in PROFINET Controller or Edge Gateway

OPC UA can be integrated into the edge device, in this case, a PROFINET Controller or PLC. In this scenario I/O data fetched from multiple PROFINET devices are aggregated and analyzed, turning the raw data into valuable information. This enables the vertical integration of the field device data into the high-level enterprise-level application.

OPC UA can be integrated into the edge device, in this case, a PROFINET Controller or PLC. In this scenario I/O data fetched from multiple PROFINET devices are aggregated and analyzed, turning the raw data into valuable information. This enables the vertical integration of the field device data into the high-level enterprise-level application.

If the existing PLC does not have support for OPC UA, then external edge gateways can be used as an alternative. In this way, data can be fetched and turned into valuable information without disturbing the existing process. This is one of the principles behind the NAMUR Open Architecture (NOA).