High-Quality Asset Health Insights + Power for Condition Monitoring Applications

Condition monitoring applications continue to grow in importance as equipment manufacturers look to increase asset utilization with real-time monitoring of equipment. The goals are to extend equipment lifespans and increase throughput by utilizing predictive maintenance techniques to reduce maintenance costs and asset downtime. Condition monitoring is also deployed to improve manufacturing quality and increase safety in manufacturing plants.

Given that unscheduled downtime can amount to nearly a quarter of total manufacturing costs, predictive maintenance has the potential to unlock significant savings and productivity. Industry market reports focused on condition monitoring show growth projections for this market between 25% and 40% CAGR driven by the two growth areas:

First is the increased deployment of smart sensors to monitor the health of the assets. Second is the increased use of artificial intelligence and advanced analytics to transform asset health data into actionable insights to deploy predictive maintenance capabilities and create new service-based, predictive maintenance business model opportunities.

Growth in new condition monitoring deployments will be across a wide range of industries, such as:

- Water and wastewater treatment

- Manufacturing

- Food and beverage

- Pharmaceutical

- Metal and mining

- Energy

- Oil and gas

Within these industries, condition monitoring applications are expanding beyond the traditional rotating equipment applications (pumps, compressors, and fans) to new applications in CNC machines, machine tools, encoders, conveyor belts, robotics, and instruments. One key challenge that needs to be solved to enable the growth of condition monitoring applications is the connectivity from the smart sensors to the higher-level management systems that act based on the insights from the asset being monitored.

Existing Communications Challenges

To-date, condition monitoring applications have used wired or wireless connectivity solutions, depending on the end application requirements. Wireless connectivity solutions have advantages in terms of ease of deployment but are often limited in bandwidth and/or battery life. Wired connectivity solutions are sometimes limited in data bandwidth, long-distance in a harsh industrial environment is not always supported and often require a separate cable for power. Existing Industrial Ethernet solutions based on 100BASE-TX/10BASE-T and PROFINET provide high data bandwidth up to 100Mb, power over a CAT-5 or CAT-6/e cable with PoE but are limited to 100m distance and don’t support hazardous area use case as they are high power solutions. Condition monitoring applications require support for potentially remote sensors that require robust communication over a long distance. The sensor node is in a space and power-constrained IP66/67 enclosure due to the harsh industrial environment it is deployed in. These constrained sensor node applications need a low power, high data bandwidth communications solution that delivers both power and data on a low cost, easy to install cable with a small cable connector to the sensor node.

Why Single Pair Ethernet / 10BASE-T1L and PROFINET?

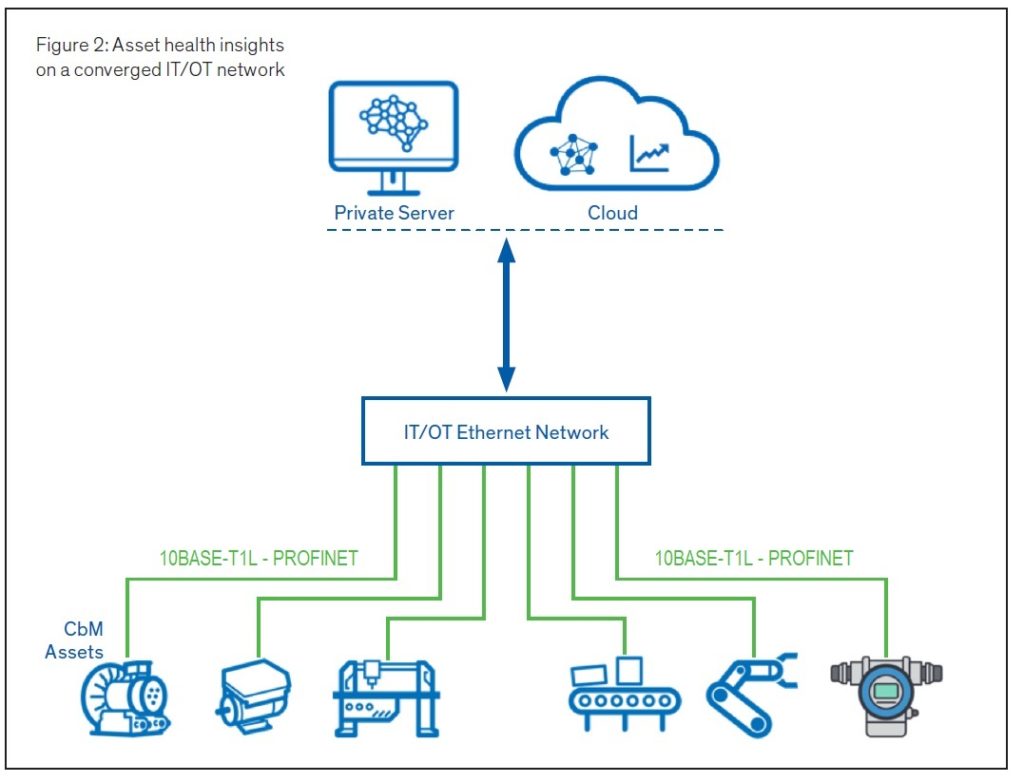

New SPE (Single Pair Ethernet) physical layer standards completed in IEEE combined with PROFINET offer new connectivity solutions for communicating asset health insights for condition monitoring applications. 10BASE-T1L is a new Ethernet physical layer standard (IEEE 802.3cg-2019) approved within the IEEE on November 7, 2019. It will dramatically change the automation industry by significantly improving operational efficiency through seamless Ethernet connectivity to field-level assets. 10BASE-T1L solves the challenges that, to-date, have limited the use of Ethernet to field assets. These challenges include power, bandwidth, cabling, distance, data islands, and intrinsically safe Zone 0 (hazardous areas) applications. By solving these challenges for both brownfield upgrades and new greenfield installations, 10BASE-T1L and PROFINET will enable new asset health insights that were previously unavailable and seamlessly communicate them to the control layer and to the cloud/private server. These new insights will awaken new possibilities for data analysis, operational insights, and productivity improvements through a converged Ethernet network from field assets to the cloud or private server (see Figure 2).

Advantages of 10BASE-T1L and PROFINET for Condition Monitoring Applications

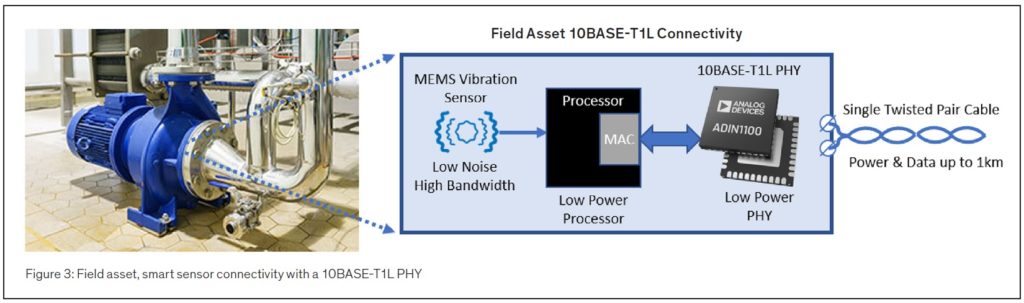

10BASE-T1L with PROFINET removes the need for complex, power-hungry gateways required by legacy communications to connect to the control and management network. It enables a converged Ethernet network across the information technology (IT) and operation technology (OT) networks. This converged network delivers a simplified installation, easy device replacement, faster network commissioning and configuration, and faster software updates with simplified root cause analysis and maintenance of field-level assets. To communicate with a 10BASE-T1L enabled field asset, a host processor with integrated medium access control (MAC), a passive media converter, or a switch with 10BASE-T1L ports is required. No additional software, no customized TCP/IP stack, and no special drivers are required (see Figure 3). This results in clear advantages for 10BASE-T1L devices:

- 10BASE-T1L is a very low power physical layer technology that can enable very low power smart sensors deployments with a high data bandwidth connectivity solution.

- A smart sensor connected with 10BASE-T1L and PROFINET is accessible over the network and can be remotely updated anywhere, at any time. Sensors are becoming more complex, and the probability of software updates increases. This is now possible within realistic periods of time via a fast Ethernet connection.

- Access to advanced Ethernet network diagnostic tools to simplify root cause analysis.

- Increased smart sensor installation flexibility via a single twisted pair cable up to 1km and beyond, with power and data on a single twisted pair cable.

- Asset health insights are now available remotely via a web server running on the field asset. They can now be accessed anywhere, reducing the need for a maintenance technician “to walk the floor” to monitor an asset’s health, a significant cost saver.

Analog Devices 10BASE-T1L PHY – ADIN1100

Analog Devices is now sampling the ADIN1100 10BASE-T1L PHY. Please see this month’s New Products article for more information.

Maurice O’ Brien

Strategic Marketing Manager

Industrial Communications

Analog Devices