The Difference Between 4–20 mA and Digital Fieldbuses

The factory floor has evolved dramatically over the years.

The first manufacturing facilities did not rely on any automated controls. All processes were based on manual operation. The first automated controls were pneumatic. Pneumatic pressure controls move pressurized or compressed air “signals” from a controller to a device through copper or plastic tubes.

After the adoption of pneumatic controls, electronic controls were introduced. The 4–20 mA convention was born in the 1950s as electronics became cheaper, and the reliability met the automation industry’s requirements. 4-20 mA provided a low-cost, easy to use solution, not subject to major signal line losses. Automation logic was accomplished using relays until being replaced by PLCs running relay ladder logic in code. The invention of the first PLC in 1968 simplified automation networks substantially and reduced hardware requirements.

In the 80s and 90s, several organizations and device manufacturers started engineering the first fieldbuses, like, for example, PROFIBUS. Fieldbuses enable 2-way digital communication. In a Fieldbus network, the devices are an integral part of the system. From the engineer’s point of view, there is no distinction between the devices and the control system. It is an integrated whole. But, why was the transition from 4-20 mA to fieldbuses made?

4-20 mA to Fieldbus Transition

4-20 mA has some limitations and disadvantages when compared to fieldbuses, such as:

- Individual cables and wires are required for each signal

- Troubleshooting can be slow due to the lack of diagnostic information

- Signals are prone to unwanted noise interference

The Fieldbus Value Proposition

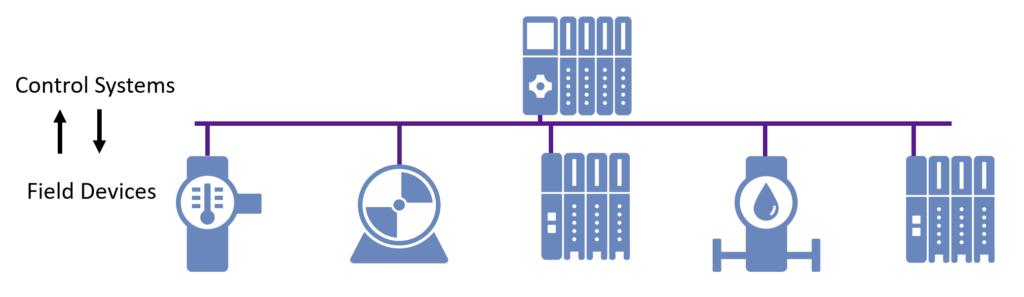

An essential advantage of fieldbuses is connecting multiple field devices over a single cable or ‘bus.’ In fieldbus networks, distributed IO mechanisms collect or distribute multiple inputs and outputs from the field into a local IO device. Then the data is transferred through just one cable to and from the PLC. This factor alone can significantly cut engineering, installation, commissioning, and maintenance costs.

Digital signals can carry more information than analog signals. They can provide diagnostic information for all of the devices in the network. That information is not only useful to resolve downtime situations but also to prevent them. Network diagnostic information is used for preventative and predictive maintenance practices and other advanced asset management techniques.

Digital signals can carry more information than analog signals. They can provide diagnostic information for all of the devices in the network. That information is not only useful to resolve downtime situations but also to prevent them. Network diagnostic information is used for preventative and predictive maintenance practices and other advanced asset management techniques.

Signal noise can interfere with both analog and digital signals; however, the amount of noise necessary to affect a digital signal is much higher. Digital fieldbuses can withstand higher exposure to electrical noise without compromising data and communication quality.

Current Network Trends

Modern automation facilities require the speed, accuracy, and versatility of fieldbuses. The greater accuracy of ‘digital’ means significant improvements in production speeds and quality. Fieldbuses deliver real-time performance for automation environments. And with the shift from analog to digital, we now have a network, and different topologies are possible.

Each fieldbus standard offers specific characteristics. PROFIBUS was introduced in the early 1990s by PI. Currently, it is the leading fieldbus technology in terms of functionality and adoption. By 2019, there were over 62 million PROFIBUS nodes installed worldwide.

Today, the trend continues with Industrial Ethernet standards, such as PROFINET. Higher bandwidth, larger message sizes, and address spaces are some benefits. Plus, multi-protocol coexistence enables modern network architectures and connections to higher-level systems.