Easy Integration of PROFINET Controllers

Many device manufacturers appreciate the easy integration of field devices with PROFINET. At first glance, this issue seems more complex for controllers because they require some initial engineering. Technology providers can help with this.

Technology provider Siemens has been collaborating with Austrian systems manufacturer Bachmann for over 20 years. At the heart of this partnership is the M1 controller family, which operates with Siemens’ PROFINET stack. The M1 controller is primarily used in harsh environments or wherever total reliability is needed – such as in power plants, wind turbines, or onboard ships.

Among its interesting capabilities is the automatic device naming enabled by neighborhood detection. For example, one high-profile client from the food industry supplies machines containing multiple pumps with a PROFINET interface, which are regularly exchanged for cleaning. This rotation has become much simpler for machine operators because it is no longer necessary to manually name the substitute pump according to its deployment location. The added pump is detected, named, initialized, and put into operation even while the control system is operating. “Our customers don’t need to program anything for this to happen,” says a satisfied Helmut Ritter, Product Manager at Bachmann.

Among its interesting capabilities is the automatic device naming enabled by neighborhood detection. For example, one high-profile client from the food industry supplies machines containing multiple pumps with a PROFINET interface, which are regularly exchanged for cleaning. This rotation has become much simpler for machine operators because it is no longer necessary to manually name the substitute pump according to its deployment location. The added pump is detected, named, initialized, and put into operation even while the control system is operating. “Our customers don’t need to program anything for this to happen,” says a satisfied Helmut Ritter, Product Manager at Bachmann.

“We have been using PROFINET to provide maximum interoperability with other automation components since 2005. Our controller can be operated as a PROFINET controller and/or device purely through the configuration, without additional hardware. As an I-Device, the M1 controller can also perform tasks autonomously – that is to say, irrespective of network connectivity. PROFINET offers particular advantages here as individual nodes in the network can be missing – as well as added or removed – without disrupting the network’s determinism,” Ritter explains. A connection is established via the controller CPUs’ existing Ethernet ports, which are then also available for other services (HTTP, FTP, MQTT, etc.).

“The Ethernet cables in the machine are not only used for commissioning and running diagnostics on the individual devices. Thanks to the prioritized PROFINET telegrams, they can also be used as field bus infrastructure and a backbone for Industry 4.0 applications at no extra cost,” Ritter continues.

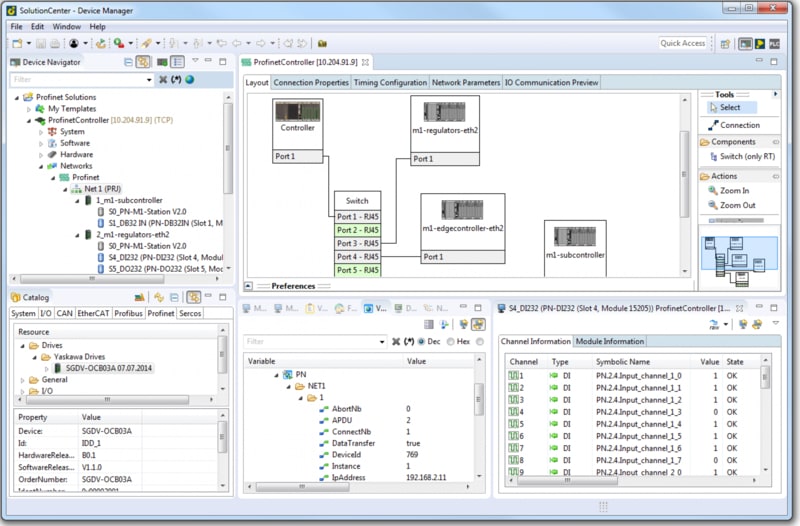

The network is configured via GSDML files in Bachmann’s central configuration and programming tool, SolutionCenter. Siemens’ PNConfigLib was also incorporated into the SolutionCenter for this purpose. Within the control software, the devices’ I/O data are shown in the controller’s process image, while quality information and diagnostic alerts are visualized as a status for the relevant data point.

Siemens’ development kits for PROFINET controllers and devices are also to thank for the smooth integration of the controller. All Bachmann products have recently undergone a comprehensive update and certification process for PROFINET. As a next step, Bachmann is working on the implementation of an F-host, which will enable PROFIsafe actors and sensors to run on a fail-safe Bachmann CPU.

More information @ www.bachmann.info