The market for robots is growing rapidly. However, integrating them into the automation world can be very laborious and correspondingly slow. A new robot profile now provides a remedy.

New Robot Systems Working Group

Many medium-sized companies, whether in the food industry, the packaging industry or electronics suppliers, are increasingly turning to robot-assisted applications (pick & place). However, if you take a look at the practical implementation, there are some challenges to overcome. This is because every robot manufacturer today brings its own world of automation with it, including hardware and software, specific programming know-how, interfaces, controllers, operating devices, engineering systems, etc.

Many medium-sized companies, whether in the food industry, the packaging industry or electronics suppliers, are increasingly turning to robot-assisted applications (pick & place). However, if you take a look at the practical implementation, there are some challenges to overcome. This is because every robot manufacturer today brings its own world of automation with it, including hardware and software, specific programming know-how, interfaces, controllers, operating devices, engineering systems, etc.

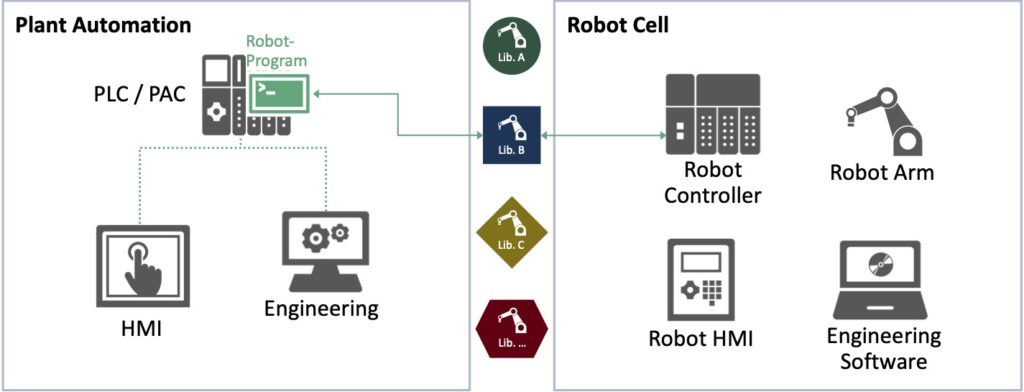

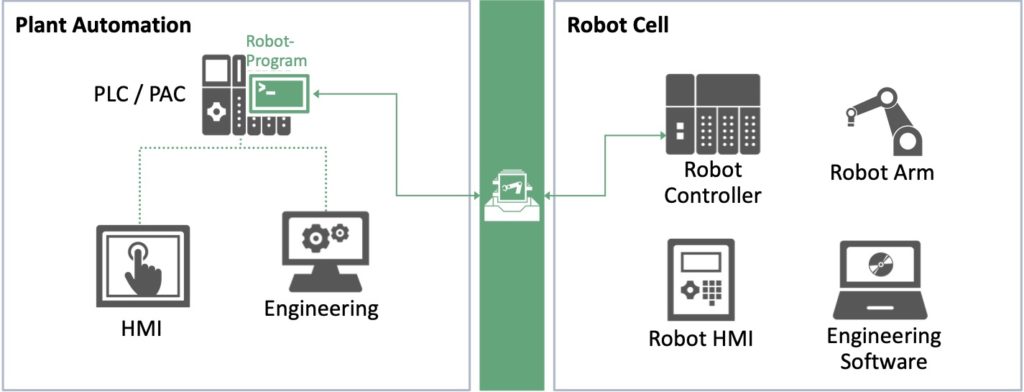

The production line is typically controlled by a PLC, and the user programs the production line application via the PLC’s programming system. If a company wants to integrate a robot into a higher-level, mostly PLC-controlled process, this is often very tedious. Engineering and commissioning in particular are associated with a high level of complexity and a great deal of effort. First, the interface itself must be defined, followed by the PLC program, and then the program must be integrated on the robot controller. The definition of the interfaces is not standardized and must therefore be created again and again. This work is time-consuming and is not the focus of a user.

Innovation Shouldn’t Slow Down

Even in later operation, the workload remains high: every system maintenance, every update, the integration of a different type of robot or even a new manufacturer entails an abundance of work. To make matters worse, robot specialists are few and far between. Therefore, such work is usually outsourced to system integrators, which in turn means effort and expense. As a result, users of industrial robots usually have to decide early into which robot type and manufacturer they want to invest their effort. Innovative new solutions are therefore used less frequently.

Uniform Interface for Robots

For this reason, there has long been a desire for users to be able to uniformly control and program the complete robot systems of different manufacturers integrated in a production line via the PLC programming system.

Leading robot manufacturers – ABB, Comau, Epson, Fanuc, Jaka, Kawasaki, Kuka, Nachi, Panasonic, Stäubli, TM Robot, Yamaha, Yaskawa – joined forces at the initiative of Siemens to develop a solution. This meant that around 70 percent of the world’s robot manufacturers were on board. It took two years to find and develop the concept, which was anything but trivial. After all, the engineering and the runtime systems in the respective robots were launched on the market decades ago in some cases and have been continuously developed over these years. To give just one example: The same movements are currently represented quite differently in the engineering.

The joint work has paid off! Now, a uniform data interface between the PLC and the robot controllers has been defined to make robot programming uniform – and thus more efficient – for PLC programmers and PLC suppliers. Via this data interface, robot programs can be written completely in the PLC by calling the robot functions and reporting the required robot state information back to the PLC. The development, elaboration, and maintenance of the new data interface were placed in the hands of PI. For the development of this new robot profile, PI has set up a new “Robot Systems” working group and launched the “Standard Robot Command Interface”.

This data interface will first be mapped to PROFINET, since PROFINET has proven itself in many applications over many years, both on the part of the robot manufacturers and on the part of the PLC manufacturers.

On the robot side, the commands are converted into the local programming environment/language via the uniform interface (interpreter). On the PLC side, templates or higher-level commands can also be created that combine several actions on the data interface.

A Single Robot Library

As in other technologies, there will be different levels or classes in the robot interface. First, there will be a defined set of functions, which are necessary for all and for simple functions. Higher-level functions can then be added as an option. The focus is still on handling functions, e.g. pick & place applications. Functions such as jog mode, teaching of path points, creation and validation of a motion profile and changing configuration data are provided for this purpose. In the future, however, it is planned to integrate other applications, such as those of welding robots, as well.

As in other technologies, there will be different levels or classes in the robot interface. First, there will be a defined set of functions, which are necessary for all and for simple functions. Higher-level functions can then be added as an option. The focus is still on handling functions, e.g. pick & place applications. Functions such as jog mode, teaching of path points, creation and validation of a motion profile and changing configuration data are provided for this purpose. In the future, however, it is planned to integrate other applications, such as those of welding robots, as well.

Now the PLC manufacturer only needs a single robot library that contains the function blocks for programming robots from different manufacturers. The robot manufacturer also only needs to implement a single interpreter for his robot control. Programming is carried out entirely by the PLC automation specialists.

Users and manufacturers are convinced that this will significantly reduce the complexity of service and maintenance in robot-based applications.

Xaver Schmidt

Xaver Schmidt

Leader

PI “Industry 4.0” Working Group