With the growing focus on digitalization, sustainability, and worker safety, PROFINET is seeing a resurgence in the use of Application Profiles. In this three-part series, we look at the three application profiles fueling this resurgence – PROFIsafe, PROFIenergy, and PROFIdrive. In two previous issues, we have already looked into PROFIsafe (see Part 1 here) and PROFIenergy (see Part 2 here). In this issue we look at PROFIdrive.

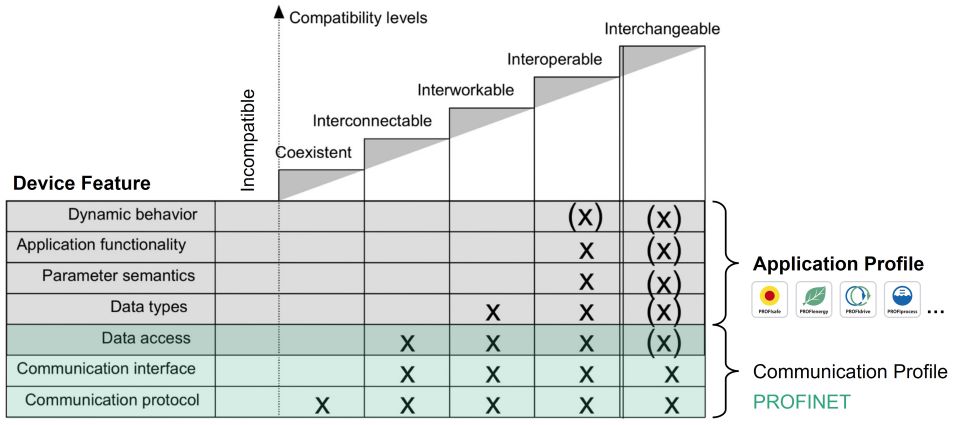

As a refresher from the previous issues, what we’re talking about, when we talk about Application Profiles, is increasing the level of compatibility between devices in a network. As can be seen in the figure below, the PROFINET specification provides the first level of compatibility by standardizing the protocol, interfaces, and data access. Here, we can achieve co-existence and interconnectability at the communication level. Application Profiles take it a step further by standardizing data types, semantics, and functionality. Here, we can achieve not only interoperability but even device interchangeability. Each Application Profile is specified and written by PI, just like the PROFINET protocol.

Application Profiles work by structuring data in a consistent object format for a family of devices. In other words, a family of devices always has its data modeled the same way. For just about every step in a manufacturing process, there is an Application Profile. In PI we have roughly two dozen in total. There are Application Profiles for low voltage switch gear, for RFID readers, for drives, encoders, and so on. The way it works is this: if a device’s description file is written to its Application Profile, then independent of vendor or type, parameters like voltage, or position, or RPM always come into your engineering tool the same way for easy integration. And while Application Profiles are extremely useful, they are optional –a device manufacturer doesn’t need to make their product compatible, it’s just that most do because of market demand. Let’s take a look at the third of three application profiles gaining momentum with this latest market demand: PROFIdrive.

PROFIdrive

The number of parameters involved with programming a drive can be staggering and this makes drive configuration a real challenge what with “set speeds” … “slope times” … “current limits”, etc., all different and disorganized from different manufacturers.

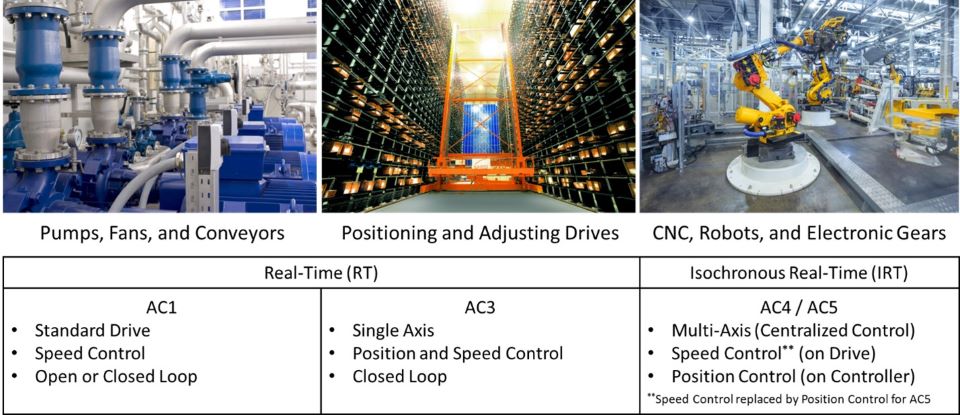

PROFIdrive helps make configuration easier by organizing all those parameters in a consistent fashion in the GSD (General Station Description) file. This organization starts by grouping drive-types into Application Classes – from simple variable speed drives to more complex, time-synchronized, multi-axis drives. There are 6 Application Classes with class 1, 3 and 4 being the most common as shown below.

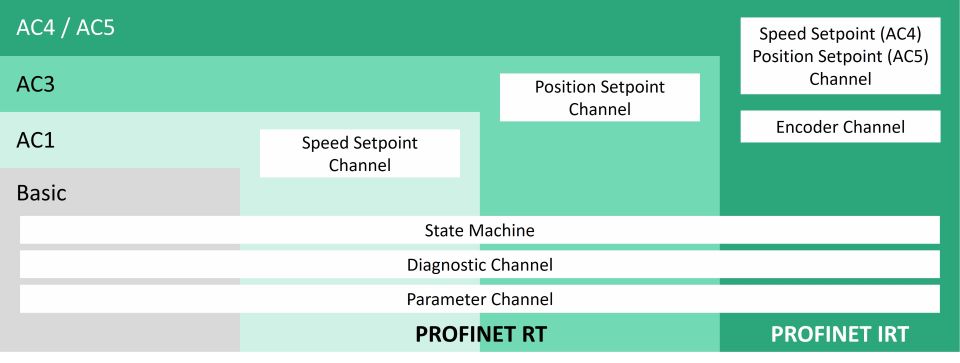

Each drive type uses the same basic interface across all Application Classes. This includes state machine control, diagnostic information, and specific drive parameters. Application Class 1 is for applications like pumps and fans. The controller sends a speed setpoint to the drive and the drive maintains speed control. Application Class 3 is for positioning applications. Here, the controller sends information pertaining to position and speed control to the drive and the drive performs autonomous, single-axis positioning. Application Class 4 is for multi-axis robot and machine-tool applications. To achieve the desired position, the controller modifies the speed setpoint based on the drive continuously sending its position data. This data exchange is why the clocks need to be synchronized between the drive and the controller. The interfaces for the various application classes can be visualized in the figure below.

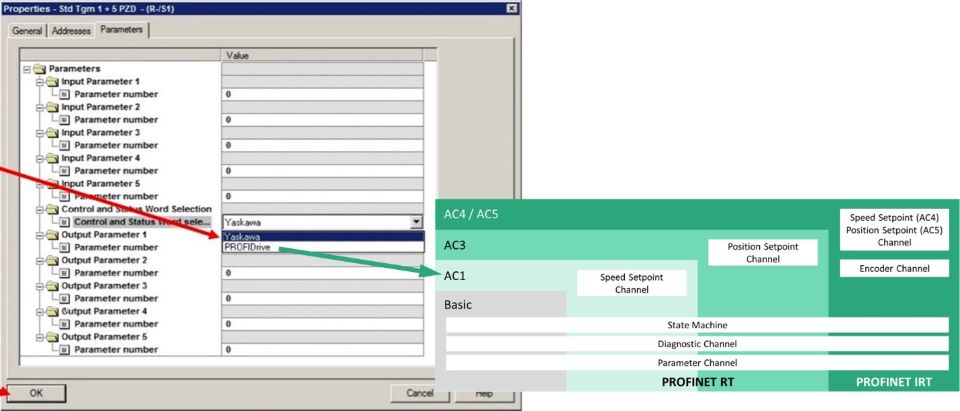

The next figure shows a screenshot on the left that is an example of using a GSD file for a drive that has PROFIdrive capabilities. During import of the GSD file, the user chooses either the drive manufacturer’s data formatting, or the standardized PROFIdrive data formatting. When PROFIdrive data formatting is selected, all the parameters for the drive’s Application Class are used – Application Class 1 as shown in this example.

PROFINET is an open communication standard that supports interoperability by standardizing communication at the protocol level and at the application level. This allows users more flexible integration and opens more possibilities when it comes to product selection.