With the growing focus on digitalization, sustainability, and worker safety, PROFINET is seeing a resurgence in the use of Application Profiles. In this three-part series, we look at the three application profiles fueling this resurgence – PROFIsafe, PROFIenergy, and PROFIdrive. We have already looked into PROFIsafe in a previous issue (see Part 1 here). In this issue we look at PROFIenergy.

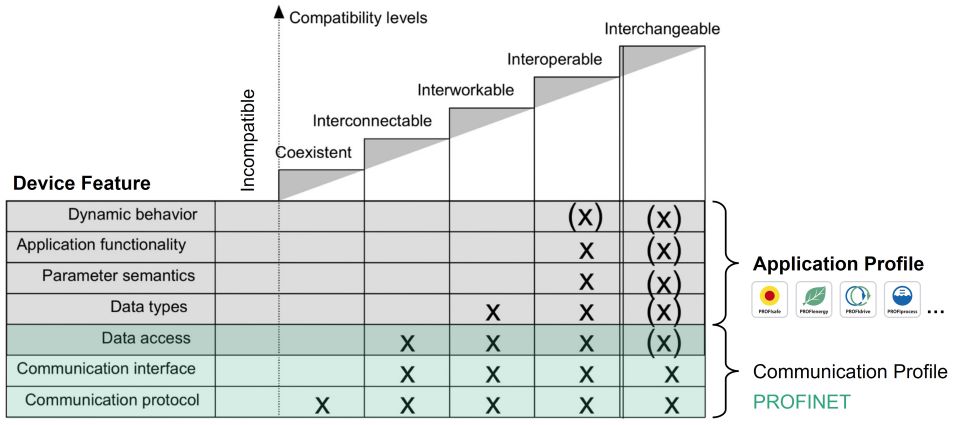

As a refresher from the previous issue, what we’re talking about, when we talk about Application Profiles, is increasing the level of compatibility between devices in a network. As can be seen in the figure below, the PROFINET specification provides the first level of compatibility by standardizing the protocol, interfaces, and data access. Here, we can achieve co-existence and interconnectability at the communication level. Application Profiles take it a step further by standardizing data types, semantics, and functionality. Here, we can achieve not only interoperability but even device interchangeability. Each Application Profile is specified and written by PI, just like the PROFINET protocol.

Application Profiles work by structuring data in a consistent object format for a family of devices. In other words, a family of devices always has its data modeled the same way. For just about every step in a manufacturing process, there is an Application Profile. In PI we have roughly two dozen in total. There are Application Profiles for low voltage switch gear, for RFID readers, for drives, encoders, and so on. The way it works is this: if a device’s description file is written to its Application Profile, then independent of vendor or type, parameters like voltage, or position, or RPM always come into your engineering tool the same way for easy integration. And while Application Profiles are extremely useful, they are optional –a device manufacturer doesn’t need to make their product compatible, it’s just that most do because of market demand. Let’s take a look at the second of three application profiles gaining momentum with this latest market demand: PROFIenergy.

PROFIenergy

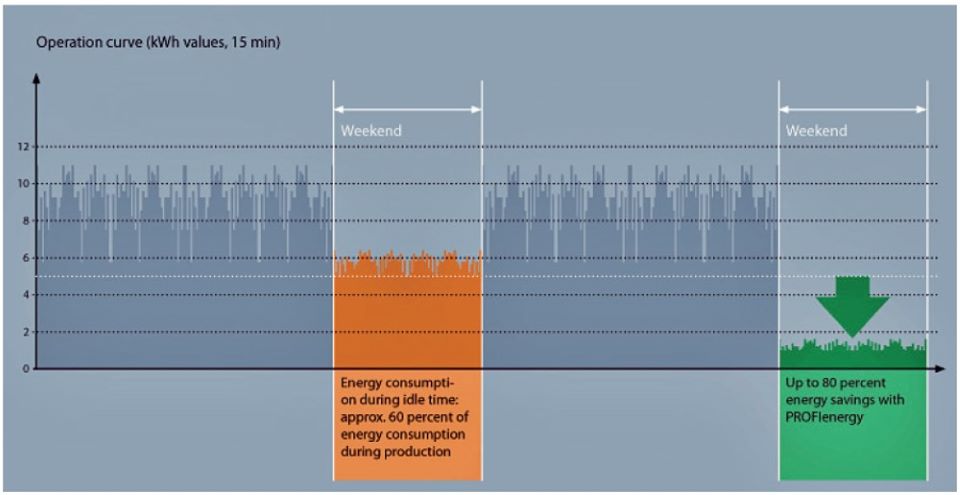

Spurred on by the automotive companies – they noticed that when they are producing cars during the weekdays, they consume a certain number of kilowatt hours, as shown in the gray color in the figure below. Whereas, on the weekends when they aren’t producing cars – when production is actually zero – they still consume roughly half the amount of energy they use during the weekdays, as shown in orange below. So the automotive companies came to PI and asked if there is anything we can do to help reduce energy consumption when they aren’t building cars – when production is zero. So we went away and created a working group and came up with PROFIenergy. PROFIenergy reduces energy consumption by roughly 80% – as shown below in green.

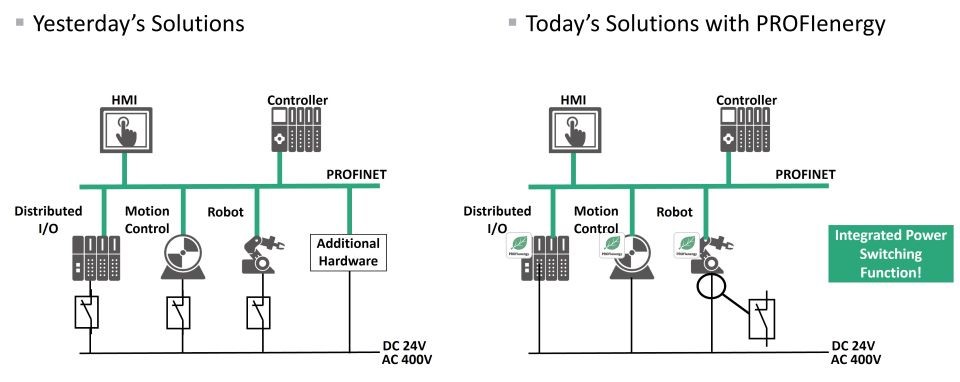

It’s not a new idea. It’s just that in the past there would be some additional hardware connected to the PROFINET network and on the other side hard contactors as shown on the left in the figure below. These contactors cut the power to the I/Os, drives, and robots on Friday evening – and then repower these devices again on Monday morning. This is certainly an excellent way to save energy when devices aren’t being used. Except what these folks noticed is that their lines didn’t run the same on Monday morning as they had before they were shut down on Friday evening! These lines are just so incredibly complex that cutting power to the devices – and then repowering them – causes the line to not restart the same way! So with PROFIenergy we get rid of all of that extra hardware, and the power saving functionality gets integrated into the devices as shown on the right in the figure below. These devices then exchange PROFIenergy messages with the controller to properly repower the devices.

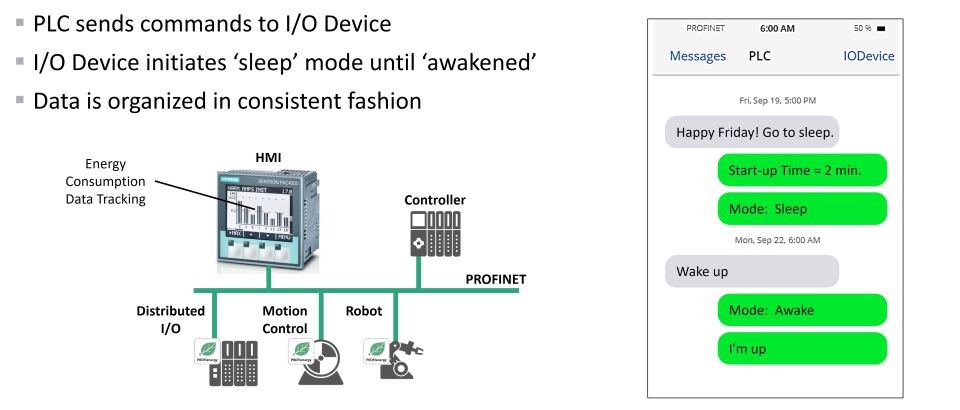

The way it works is this: when it comes time to power down the lines on Friday evening the PLC tells the devices to go to sleep. This is a good analogy to the sleep function on your laptop where you tell it to go to sleep when it’s not doing anything. When devices receive the sleep command, they reply with their start-up time – because each device has its own unique power-up sequence. For example, an end-of-arm tool on a robot may need a longer time to warm-up than a drive in a conveyor belt. Then, when it is time to restart the line, the PLC tells devices to wake up based on their start-up time. A conceptual dialog is shown below on the right. And finally data is organized in a consistent fashion, – which is true for all Application Profiles – so, we can do things like report real-time energy consumption as we are showing below on the HMI.

The way it works is this: when it comes time to power down the lines on Friday evening the PLC tells the devices to go to sleep. This is a good analogy to the sleep function on your laptop where you tell it to go to sleep when it’s not doing anything. When devices receive the sleep command, they reply with their start-up time – because each device has its own unique power-up sequence. For example, an end-of-arm tool on a robot may need a longer time to warm-up than a drive in a conveyor belt. Then, when it is time to restart the line, the PLC tells devices to wake up based on their start-up time. A conceptual dialog is shown below on the right. And finally data is organized in a consistent fashion, – which is true for all Application Profiles – so, we can do things like report real-time energy consumption as we are showing below on the HMI.

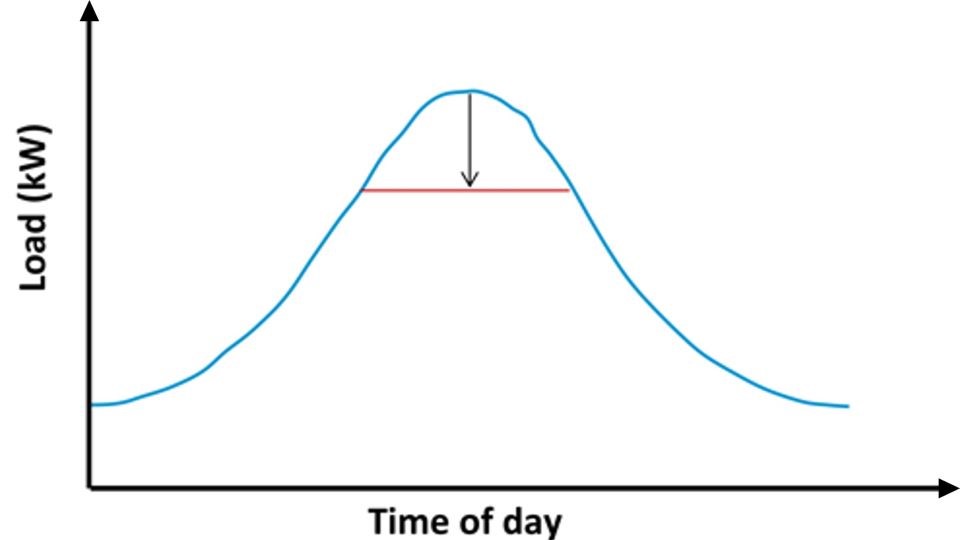

Organizing data in a consistent fashion also allows you to do some really incredible things. For example, one major automotive manufacturer collects and analyzes PROFIenergy data to do something called “peak shaving”. Utility companies bill their industrial customers differently from how they bill their residential customers. Industrial customers are billed not only on how much energy they consume in a given billing period, but also if there are any demand peaks. So if they consume X number of kilowatt hours in July and the same X kilowatt hours in August –but in August, there was a big demand spike, their August bill will be much, much higher, because utility companies don’t like demand spikes since it is hard on the power grid.

As shown in the figure below, by collecting and analyzing PROFIenergy data, this company can recognize when they are approaching a peak in their energy demand. So, they pause production for a little while, and there’s actually an ROI on that, because of the savings on the utility bill. Even though this is not part of PROFIenergy, it is enabled by it, because of the consistent organization of data in the Application Profile.

To learn more about PROFIenergy, checkout these two White Papers: The PROFIenergy Profile and PROFIenergy Study

In the next issue of PROFInews, we will look at Part 3, the third application profile gaining momentum: PROFIdrive.