Historically, industrial sensors were and still are in many cases analog. They include a sensing element and some way to get the sensing data to a controller. Data was unidirectional analog. Then came binary sensors, which provided a digital on/off signal, and included a sensing element: inductive, capacitive, ultrasonic, photoelectric, etc. with a semiconductor switching element. The output could be: high-side (HS) switching (PNP) or low-side (LS) switching (NPN) or push-pull (PP). But data was still limited to unidirectional communication from the sensor to the master, had no error control, and still required a technician on the factory floor for tasks such as manual calibration.

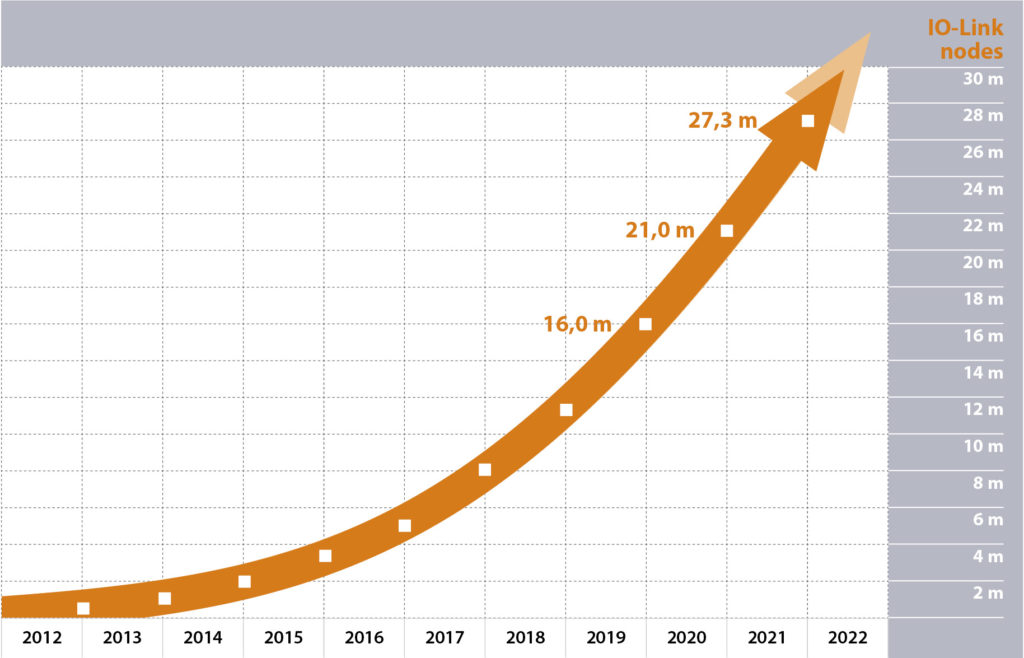

A better solution was needed to meet the demands of “Industry 4.0”, smart sensors, and reconfigurable factory floors. The solution is the IO-Link protocol, a relatively new standard for industrial sensors that is showing a phenomenal growth trajectory. The IO-Link organization estimates that over 27 million IO-Link enabled nodes are being used in the field to date. That number is still growing.

IO-Link is a standardized technology (IEC 61131-9) that regulates how sensors and actuators in industrial systems interact with a controller. IO-Link is a point-to-point communication link with standardized connectors, cables, and protocols. The IO-Link system is designed to work within the industry standard 3-wire sensor and actuator infrastructure and comprises an IO-Link Master and IO-Link Device products.

IO-Link communication is between one master and one device (sensor or actuator). Communication is binary (half-duplex) and is limited to a distance of 20m, using unshielded cables. Communication requires a 3-wire interface (L+. C/Q, and L-). The supply range in an IO-Link system is 20V to 30V for the master and 18 to 30V for the device (sensor or actuator).

Analog Devices’ IO-Link handbook1 elaborates IO-Link advantages as follows:

“IO-Link is a technology that enables a traditional binary or analog sensor to become an intelligent sensor that no longer just gathers data but allows a user to remotely change its settings based on real-time feedback obtained on the health and status of other sensors on the line, as well as the manufacturing operation it needs to perform. IO-Link technology enables sensors to become interchangeable through a common physical interface that uses a protocol stack and an IO Device Description (IODD) file to enable a configurable sensor port. It is truly plug-and-play ready while providing the ability to reconfigure parameters on-the-fly.”

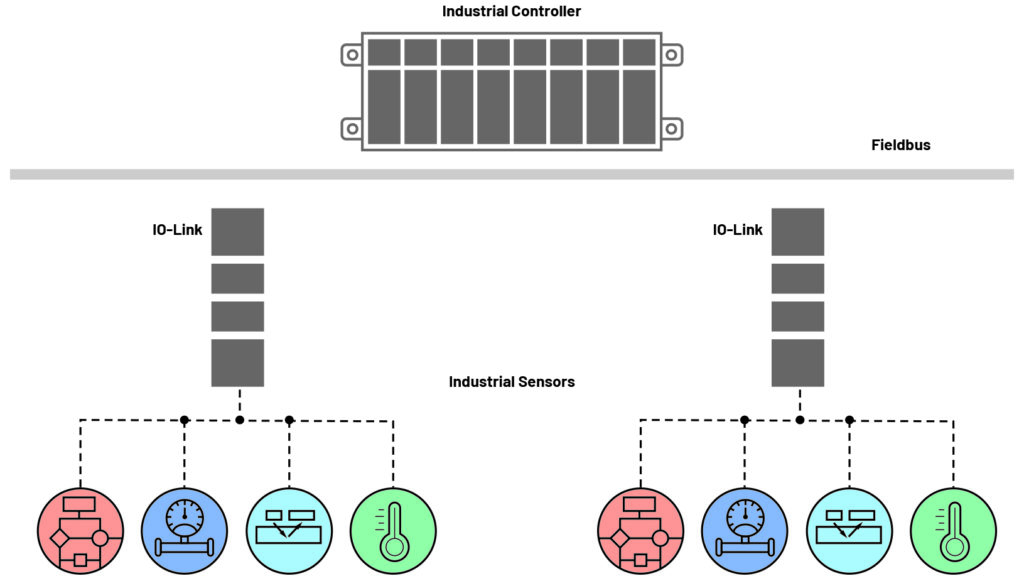

Within the factory network hierarchy, the IO-Link protocol sits at the edge, which are typically sensors and actuators as shown in Figure 2. Many times, the edge devices communicate to a gateway that translates the IO-Link protocol to the fieldbus of choice.

Designing IO-Link Sensors

Industrial field sensors must be rugged, small, and very energy efficient so that the heat dissipation is kept to a minimum. Most IO-Link sensors have the following components:

- Sensing element with the associated analog front end (AFE)

- A microcontroller that processes data, and in the case of an IO-Link sensor, also runs the lightweight protocol stack.

- An IO-Link transceiver that is the physical layer.

- Power supply and in many cases protection (TVS for surge, EFT/burst, ESD, etc.).

Heat Dissipation (Power Efficiency)

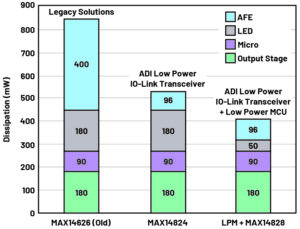

Once we understand the typical components, we can look at how a hypothetical sensor power is budgeted. See Figure 3. All of these numbers are estimates. They show that the transceiver (output stage) power consumption matters when budgeting the total system power consumption of a sensor.

Let’s start at the left-most side, which for an older generation of IO-Link sensor. That way it becomes clearer how advances in technology in the microcontroller (MCU) and the output stage (i.e., the transceiver) has contributed to the lowering of the total system power over the years.

Original or first generation IO-Link transceivers consumed 400mW or higher. The newest low-power Analog Devices IO-Link transceivers consume less than 100mW. Also, the MCUs have helped. A legacy MCU consumes as much as 180mW, but the newer low-power MCU can go down to 50mW.

A state-of-art IO-Link transceiver coupled with a low-power MCU can keep the total sensor power budget can be in the range of 400mW to 500mW.

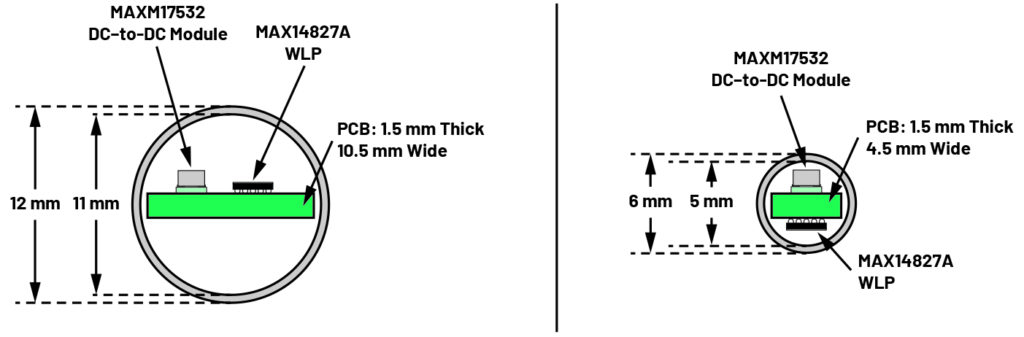

Power dissipation is directly related to heat dissipation. The smaller the sensor the more stringent the power dissipation specification. By some estimates, an 8mm diameter (M8) enclosed cylindrical IO-Link sensor will specify a maximum power dissipation of 400mW and a 12mm diameter (M12) enclosed cylindrical IO-Link sensor will specify a maximum power dissipation of 600mW.

And the technology keeps getting better. One of the new IO-Link transceivers from Analog Devices, the MAX14827A, dissipates a remarkably low 70mW when driving a 100mA load. This is achieved by optimizing the technology to deliver a very low 2.3Ω (typ.) RON (on-resistance).

Size of IO-Link Sensor

After heat dissipation, size is the next biggest concern for all industrial sensors, and it applies as well to the new IO-Link sensors. Board space becomes increasingly at premium as we migrate to a smaller form-factor.

Figure 4 shows that for a 12mm diameter housing, the transceiver (in a wafer level package – WLP – package) and the DC-DC can sit side by side on a regular PCB which has 10.5mm width. There is still room for vias and wires on the same side. If the sensor housing is 6mm, then the PCB width is down to 4.5mm. Then the chips have to be mounted on both sides of the PCB even with small WLP packages.

To enable these sizes, the transceiver must be available in a wafer-level package (WLP) that allows for the smallest size. This size limitation is also one of the reasons we have integrated a DC-DC inside our newest IO-Link transceiver as shown before.

But most industrial sensors also must be designed to work in a rugged environment, which means they must incorporate protection circuitry such as TVS diodes, which are not shown in Figure 5. This is where it is important to pay attention to the Absolute Maximum Ratings specification for the IO-Link transceivers.

Let’s elaborate: Why does 65V Absolute Maximum Ratings on the IOs reduce the size of the sensor subsystem? Typically, the sensor needs to survive surge pulses between the 4-pins: GND, C/Q, DI, DO. Analog Devices’ IO-Link transceivers have a spec of 65V Absolute Maximum Ratings. If we take an example of a 1KV at 24V surge between C/Q and GND.

- Voltage between C/Q and GND = TVS clamp voltage + TVS forward voltage

With the higher Absolute Maximum Ratings specification, the designer can use a small TVS diode such as SMAJ33 whose clamp voltage is 60V at 24A, and TVS forward voltage is 1V at 24A.

- Voltage between C/Q and GND = 61V

This value above is within the Absolute Maximum Ratings specification of the Analog Devices transceiver.

However, if the Absolute Maximum Ratings specification is lower, typically in the industry it is around 45V, then a much larger TVS diode such as the SMCJ33 is required to clamp the voltage down to an acceptable level. This diode is more than 3x the size than the one required for the Analog Devices transceiver.

The size impact of a larger TVS diode in the overall sensor design is significant if the transceiver Absolute Maximum (Abs Max) ratings specification is lower. Table 1 shows an estimated difference in the PCB area. The assumption here is that the sensor must be able to withstand a high-level surge of ±1KV/24A.

| IO-Link TRANSCEIVER WITH ABSOLUTE MAXIMUM RATING 65V | IO-Link TRANSCEIVER WITH ABSOLUTE MAXIMUM RATING 45V | |

| Smallest TVS Diode | SMAJ33 | SMCJ33 |

| Max Voltage | 61V | 45V |

| Total PCB Area | 40.5mm2 | 144mm2 |

Table 1: Advantages of 65V Absolute Maximum Rating on Sensor Size

The next generation of IO-Link transceivers have even improved upon this. The newer IO-Link transceivers from Analog Devices now feature an integrated protection on IO-Link line interface pins (V24, C/Q, DI, and GND). All pins feature integrated ±1.2kV/500Ω surge protection. In addition, all pins are also reverse-voltage protected, short-circuit protected and hot-plug protected.

Even with all the integrated protection features as well as the integrated DC-DC buck regulator, these devices are available in a tiny WLP package (4.1mm x 2.1mm); enabling a really small IO-Link sensor design.

CONCLUSION

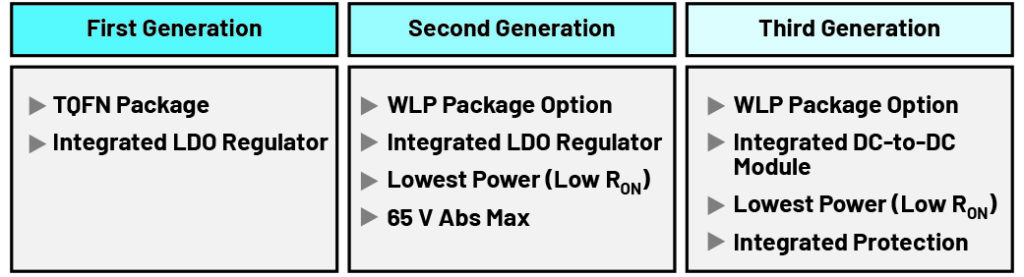

Figure 5 shows a high-level progression of the IO-Link transceiver technology from Analog Devices.

The first-generation IO-Link transceiver technology came in easy-to-use TQFN packages with integrated LDOs that would meet the needs of a small sensor design. As power and size considerations mounted, the second-generation transceiver technology optimized power consumption by moving to a technology that gave us lower RON to further reduce power consumption and were made available in even smaller WLP packages.

The newest generation of transceivers recognize the need to integrate both the protection and a high-efficiency DC-DC buck regulator to further reduce the size and the heat dissipation of the sensor subsystem.

As IO-Link technology gets deployed in even more industrial sensors, these device specifications are key to implement small, ruggedized, power-efficient sensors.