About the Client

The client is a leading e-commerce company, considered one of the most valuable global brands. The client operates upwards of 150 warehouses worldwide where associates pick, pack, and ship customer orders of diverse sizes and shapes.

Customer’s Challenge

The client uses SINAMICS drives in some of their warehouses in India for controlling the conveyor systems in the distribution lines. These conveyor systems distribute the products to various delivery vehicles. The client faced intermittent communication issues in their drives on a PROFINET network, which affected their continuous work. This was particularly recurrent in the peak holiday seasons, where due to continuous operations, the conveyors under the tremendous load experienced intermittent tripping. These network issues led to operational disturbances and decreased productivity in their warehouses.

The client uses SINAMICS drives in some of their warehouses in India for controlling the conveyor systems in the distribution lines. These conveyor systems distribute the products to various delivery vehicles. The client faced intermittent communication issues in their drives on a PROFINET network, which affected their continuous work. This was particularly recurrent in the peak holiday seasons, where due to continuous operations, the conveyors under the tremendous load experienced intermittent tripping. These network issues led to operational disturbances and decreased productivity in their warehouses.

Utthunga’s Solution

Utthunga is an authorized partner for Indu-Sol GmbH’s PROFINET/PROFIBUS network diagnostic solutions in India. Utthunga used Indu-Sol’s PROFINET network diagnostic solutions in the client’s warehouses to resolve the issue. This led to efficient production lines operating on a stable PROFINET network.

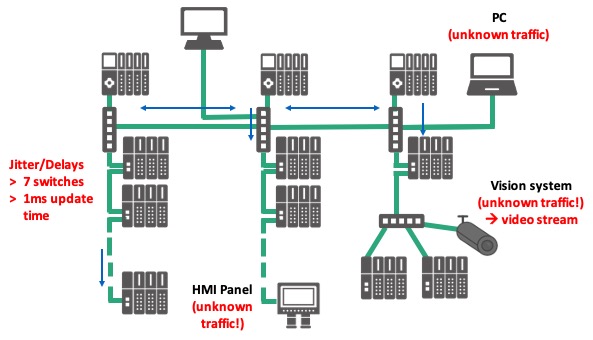

A diagnostic tool was installed in four separate warehouses to find the root cause. The issues reported were:

- Line depth was not as per PI standards

- Network was occasionally overloaded with packets

- Lack of industrial-rated switches and connectors

Line Depth & Load Ratio

| Maximum line depth with update time | ||||

| Update time | 1 ms | 2 ms | 4 ms | 8 ms |

| Line depth | 7 | 14 | 28 | 58 |

The standard line depth for a 2 ms update time should not be more than 14 devices, according to the PROFINET guidelines. In the client’s case, the line depth was 24, creating jitter on the network which led to intermittent tripping.

Unknown TCP/IP traffic was also interfering with PROFINET packets. An HMI and CCTV were also connected directly to the PROFINET network, which led to an increase in the bandwidth utilization (load) ratio. Traffic spikes therefore couldn’t be handled properly as the network would become overloaded. Other network diagnostic devices were employed to understand the issues better.

Permanent Monitoring Solution

The PROFINET-INspektor® NT evaluates telegrams of the logical data traffic and displays events (error telegrams, missing RTC packets, jitter) including any alarms that may have been triggered. The diagnosis takes place during normal production. Other aspects like data throughput, load ratio, network load and device failures are also continuously monitored. Through appropriate event-oriented triggers, the complete telegram sequence before and after each error are recorded for analysis.

Physical Layer Tester

The PROlinetest supports troubleshooting of PROFINET/Ethernet networks with copper lines. The diagnostic tool for the physical offline analysis inspects the network for the correct packaging of the wire pairs and shielding. Additionally, the continuity tester measures the total length of the cable and facilitates troubleshooting by locating installation problems accurate to the meter.

EMC Checker

The leakage current clamp EMCheck® LSMZ I is especially designed for measuring leakage and shield currents in the frequency band of 50/60 Hz and 5 Hz–1 kHz. The adjustable measuring range is arranged in levels from 30 μA – 100 A, whereupon the lower range is of special interest for any shield current measurement in a data cable. By not following proper grounding and shielding procedures, sporadic problems in data communication can sometimes be caused by interference produced by high-frequency shield currents.

Topology Documentation

The PROscan Active® V2 software is used to describe and display the PROFINET network in detail. In addition to the current topology, subscriber information such as PROFINET names, IP/MAC addresses, subnet masks, hardware and software versions, as well as device types and associated port statistics are displayed. Additional information about line lengths, loss reserves (if polymer fiber), and wiring changes can be captured and displayed.

Recommendations to the Client

Based on the various tests and reports, it was recommended that the client make changes to their PROFINET network in the warehouses as per the PROFINET guidelines, and to use managed industrial-rated switches for better performance. By implementing these solutions the client avoided network failures causing plant outages extra maintenance costs for the time spent troubleshooting such issues. Furthermore, the client was able to:

- Pinpoint root causes and improve operational efficiency

- Achieve continuous production even during peak production times

- Improve its network infrastructure resulting in high plant availability